Mechanical repair kit for kilns

A technology for maintenance tools and kilns, which is applied in the direction of manufacturing tools, wrenches, wrenches, etc., can solve problems such as difficult maintenance of raceway kilns, affecting normal production, and difficult maintenance, so as to improve maintenance work efficiency and shorten maintenance. The effect of low time and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

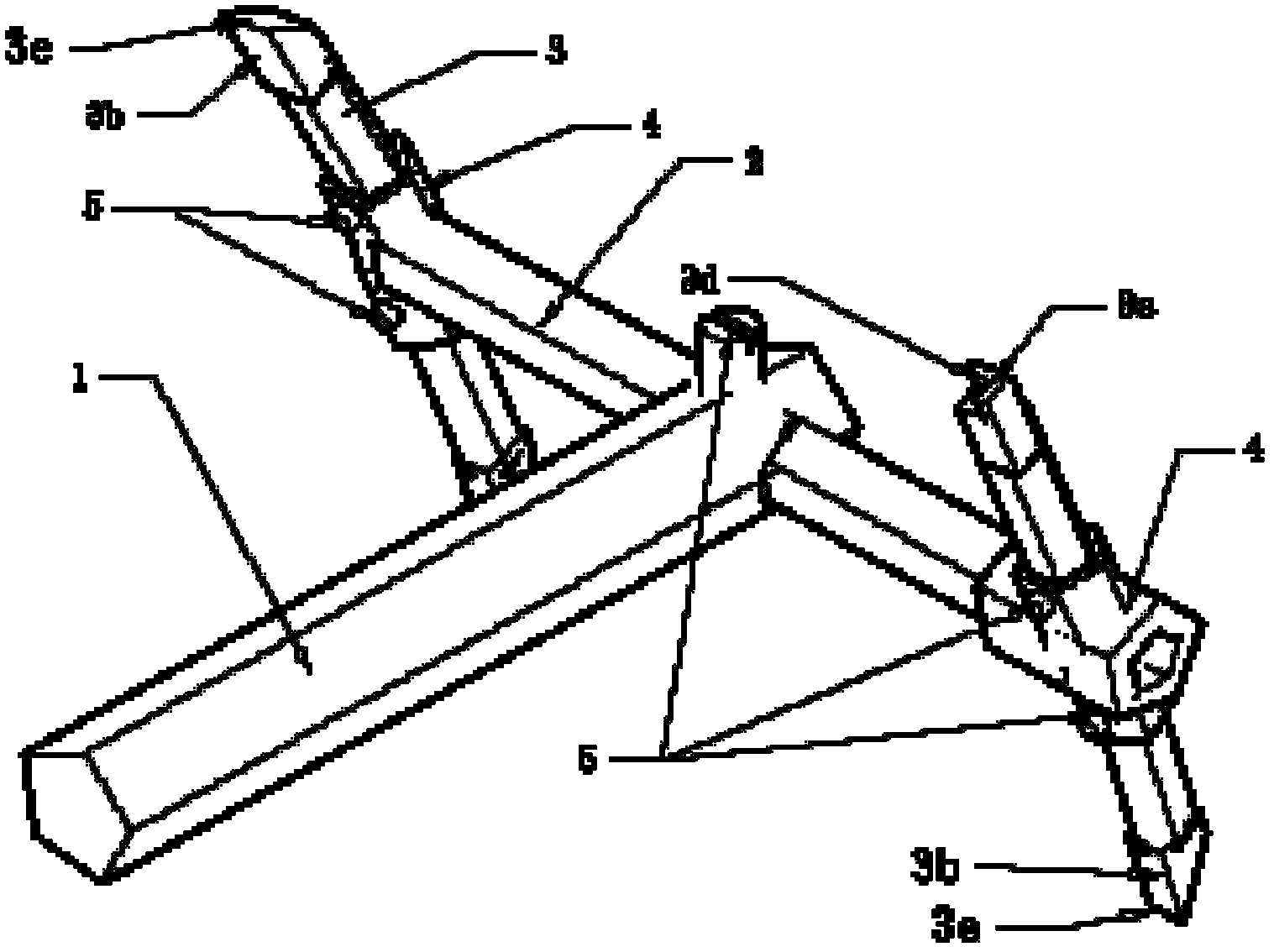

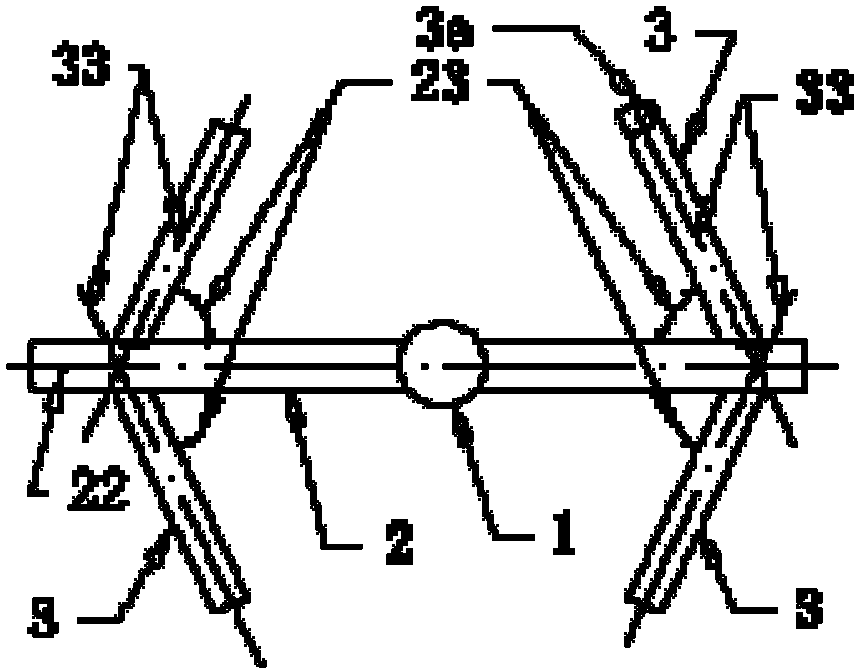

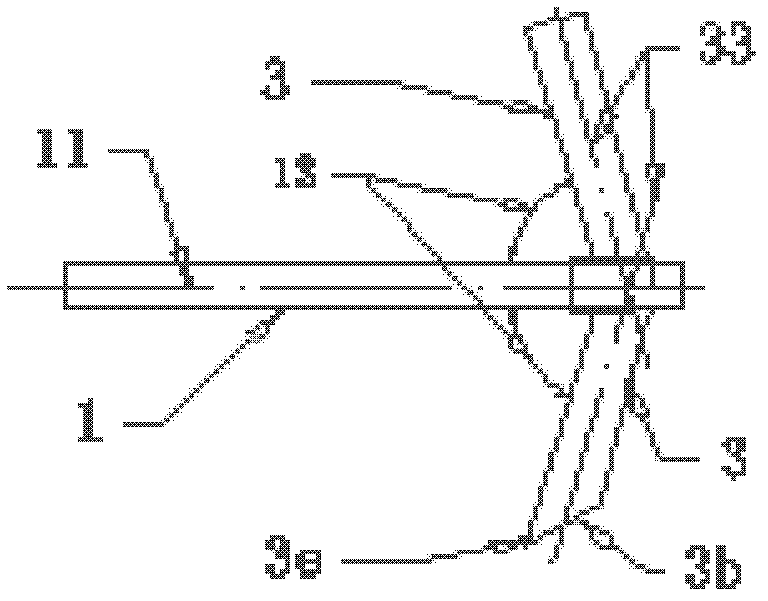

[0016] The present invention will now be further illustrated through embodiments and in conjunction with the drawings. Such as Figure 1-5 As shown, as shown, the torsion bar 2 is fixedly connected to one end of the wrench rod 1 from the middle of the wrench rod 1 through the hexagon socket provided on one end of the wrench rod 1 through the screw 5 and the wrench rod 1. The hole joint 4 is fixedly connected to the two ends of the torsion bar 2 through a hexagonal inner hole or through hole on one side of the torsion bar 2 through a screw 5; two claw rods 3 located on opposite sides of the wrench rod 1 respectively pass through an inner hexagonal hole joint from one end The upper and lower hexagon sockets on 4 are fixedly connected to the two ends of the torsion bar 2 with screws 5 facing away from each other; the torsion bar 2 and the claw bar 3 are respectively the part where the wrench rod 1 and the torsion bar 2 are connected with the hexagon socket joint 4 All are hexagon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap