Foam groover

A slotting machine and foam technology, which is applied in the field of foam sheet processing equipment, can solve problems such as inconvenient use and complex structure, and achieve the effects of easy implementation, good effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

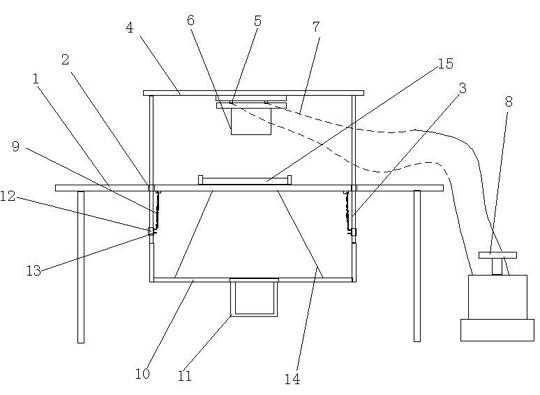

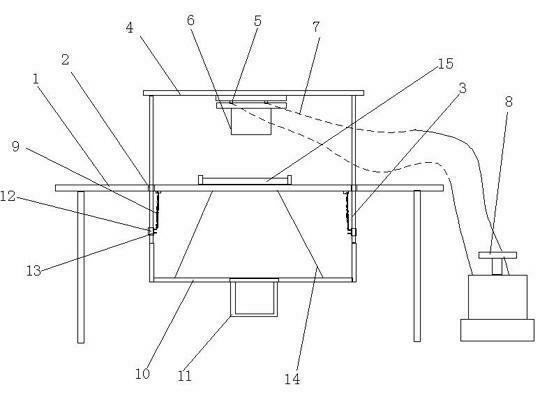

[0013] Examples such as figure 1 As shown, a foam slotting machine is characterized in that it includes a workbench 1, two through holes 2 are arranged at the center of the workbench 1, and a cross bar and a vertical bar are arranged through the through holes 2. 3 is a frame-shaped frame that can move up and down. In the middle of the upper cross bar 4 of the frame-shaped frame, an electrothermal foam grooving device is provided. The electrothermal foam grooving device includes a Frame 5, the bottom of the frame 5 is connected to a U-shaped metal frame 6, the two ends of the metal frame 6 are connected to a lead 7, and the other end of the lead 7 is connected to a low-voltage controller 8 that is powered on. The frame frame is : be arranged on two tension springs 9 that are connected between the two vertical bars 3 of described frame frame and the bottom surface of workbench 1, also be provided with pedal 11 on the lower cross bar 10 of frame frame .

[0014] An adjustment b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com