Sawing tool for plywood test piece

A plywood and test piece technology, applied in other plywood/plywood appliances, manufacturing tools, circular saws, etc., can solve the problem that the personal safety of operators is difficult to guarantee, the size of the test piece is difficult to meet the standard requirements, and the sawing test piece is consistent It can improve the positioning accuracy, reduce the operation fatigue and improve the consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

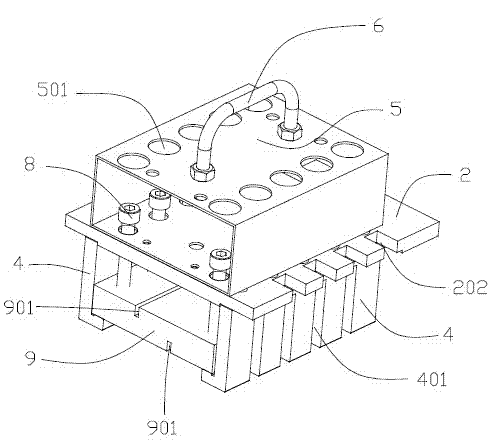

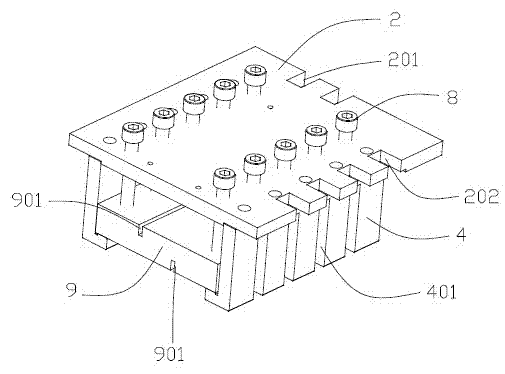

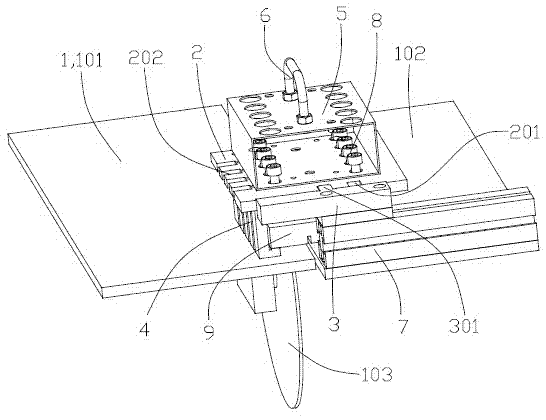

[0016] see Figure 1-Figure 4 , a plywood test piece sawing tool, which realizes the sawing of the plywood test piece by cooperating with a sliding table saw 1 . The table saw 1 is usually provided with a fixed platform 101 , a rotary saw blade 103 disposed under the fixed platform 101 and a movable platform 102 . The sawing tooling includes a clamping mechanism and a positioning mechanism. The clamping mechanism includes an upper plate 2 , support plates 4 fixed on both sides of the upper plate 2 , and clamping screws 8 arranged on the upper plate 2 and located inside the support plate 4 . The positioning mechanism includes slotted positioning grooves 201 and divided positioning grooves 202 respectively arranged on the adjacent two sides of the upper plate, and a positioning block 3 fixed on one side of the movable table 102 of the sliding table saw 1 through a connecting block 7, and the positioning block 3 is provided with a positioning tooth 301 that fits and movably eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com