Die for making porous bricks by using mud and method for forming porous bricks by using die

A technology for mold forming and porous bricks, which is applied in the field of equipment for making porous bricks, mold forming porous bricks, and molds for making silt porous bricks. Convenient and fast, simple design, and the effect of improving output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

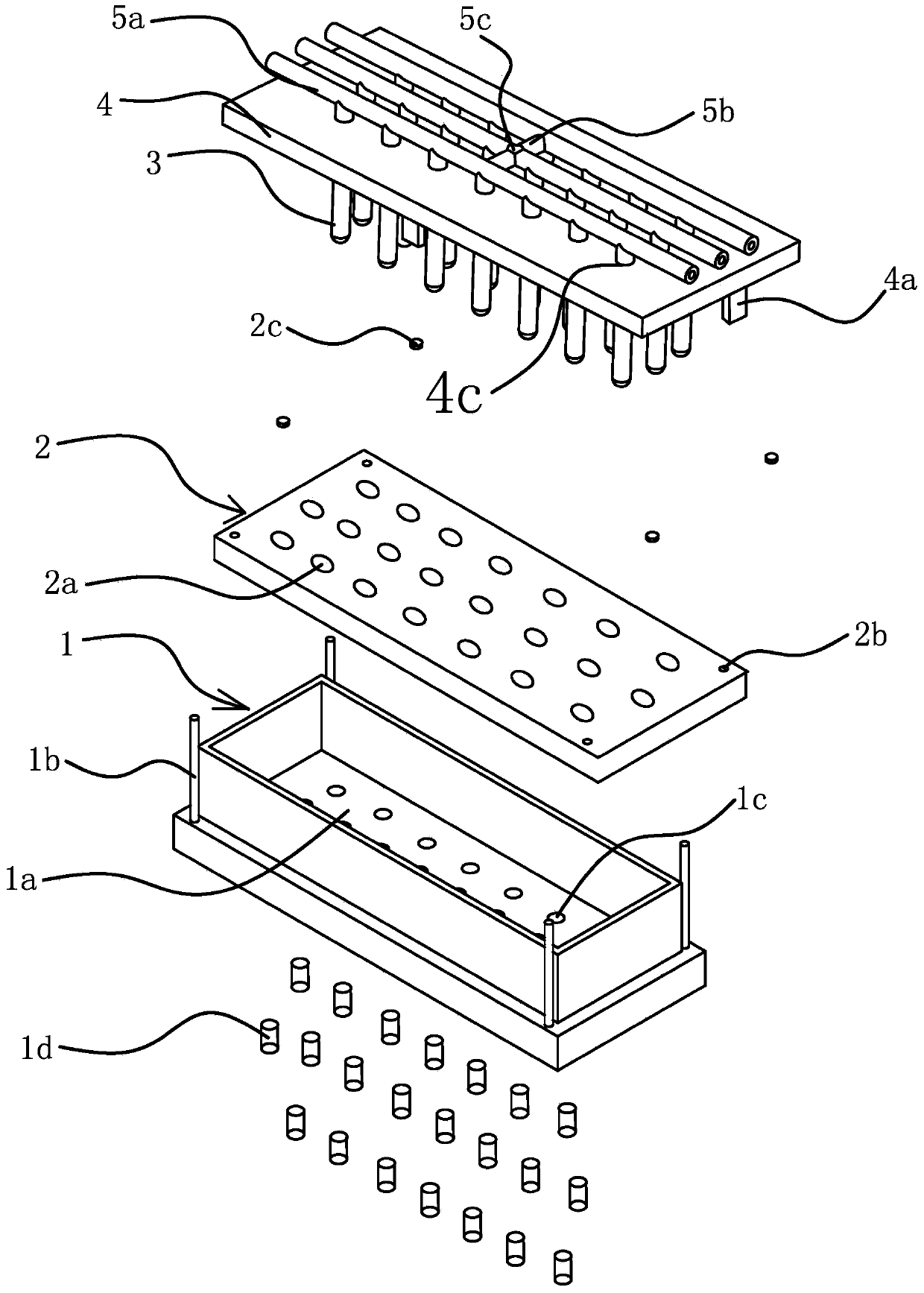

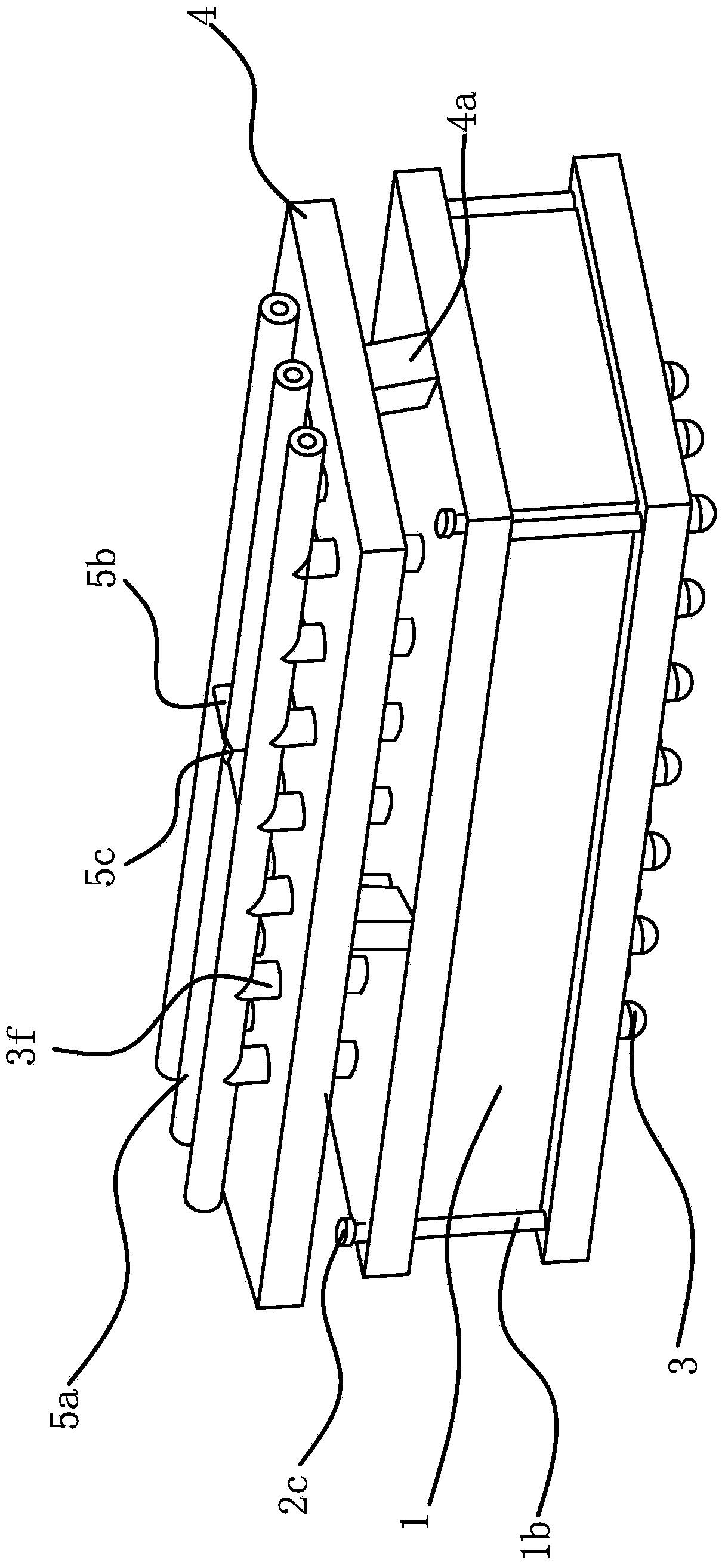

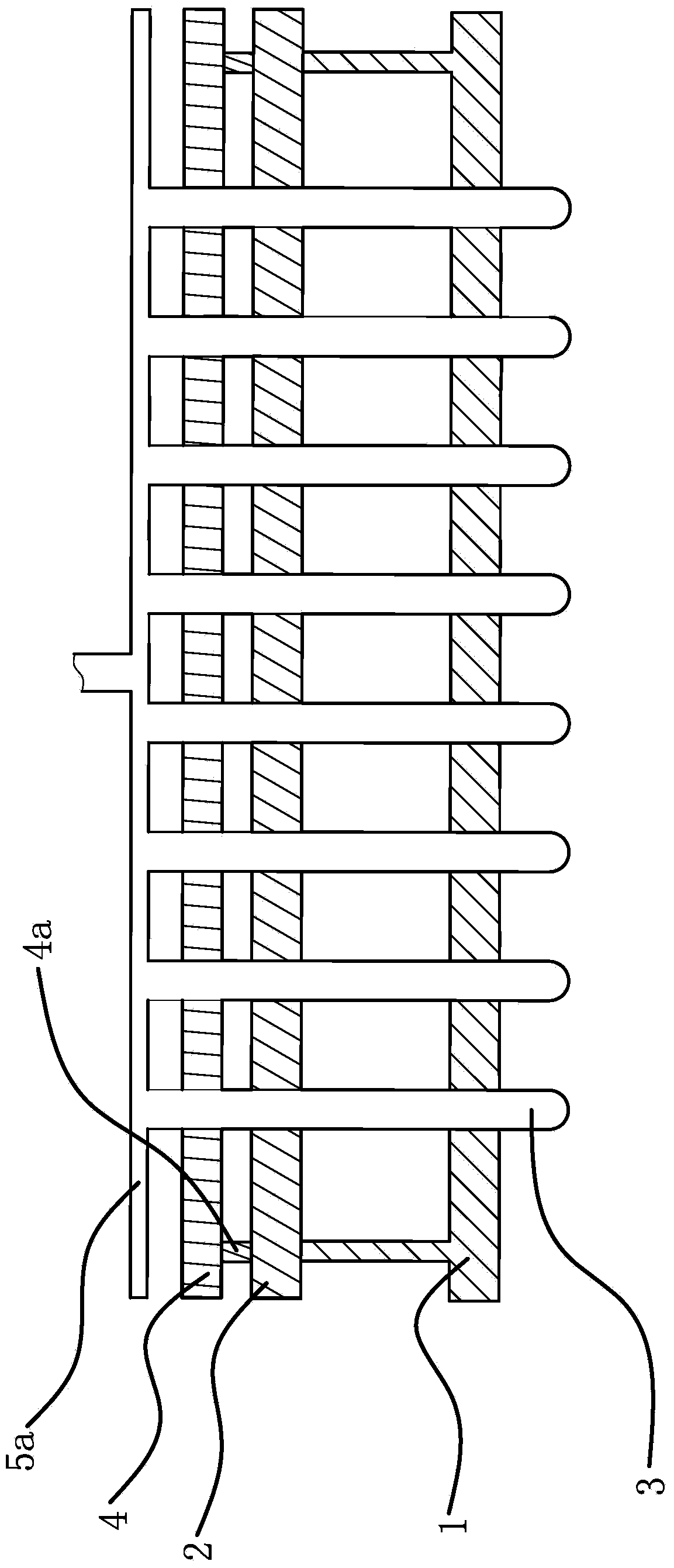

[0042] Such as Figure 1 to Figure 4 As shown, a mold for making mud porous bricks includes a bottom mold 1 with a mold cavity 1a, a cover plate 2 with a mold hole 2a, and several rod-shaped core assemblies 3 that can expand and contract in the radial direction.

[0043] The bottom surface of the bottom mold 1 is provided with a relief through hole 1c which has a function similar to that of the mold hole 2a on the cover plate 2. Each relief through hole 1c is blocked with an elastic rubber part 1d, and the elastic rubber part 1d is fixed on the bottom. On the lower bottom surface of the mold 1, before the mud is filled into the mold cavity 1a, an elastic rubber member 1d is used to block the relief through hole 1c, so that the mud can be prevented from leaking from the relief through hole 1c after the mud fills the mold cavity 1a Go; the number of through holes 1c is the same as the number of die holes 2a on the cover plate 2 and the number of core components 3, and the positi...

Embodiment 2

[0056] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the bottom surface of the bottom mold 1 with the mold cavity 1a is a closed bottom surface, and in the process of utilizing silt to form porous bricks, the mold core The component 3 passes through the mold hole 2a on the cover plate 2, and penetrates the mud until it touches with the bottom surface of the bottom mold 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com