Vehicle cooling system

A technology for cooling equipment and automobiles, applied in heating/cooling equipment, electric vehicles, air handling equipment, etc., which can solve problems such as cooler pressure and temperature level adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

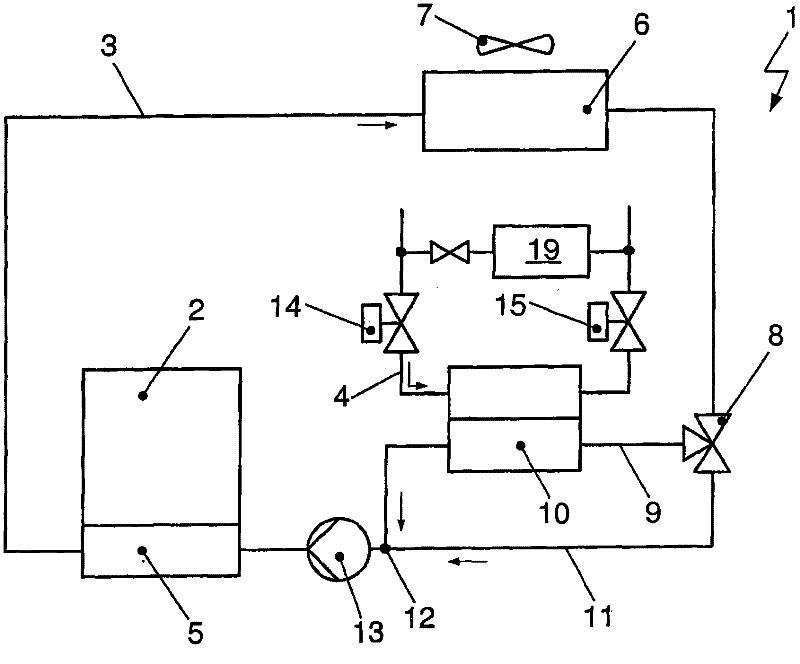

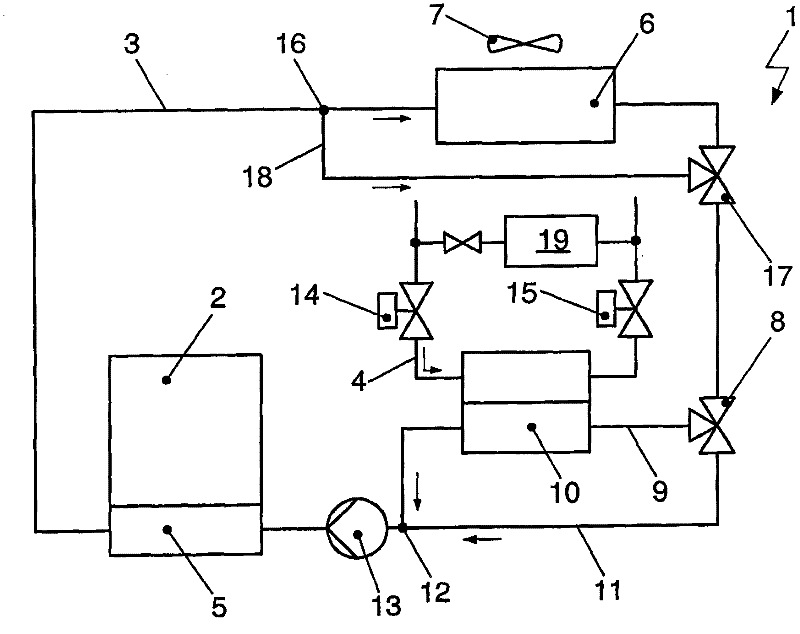

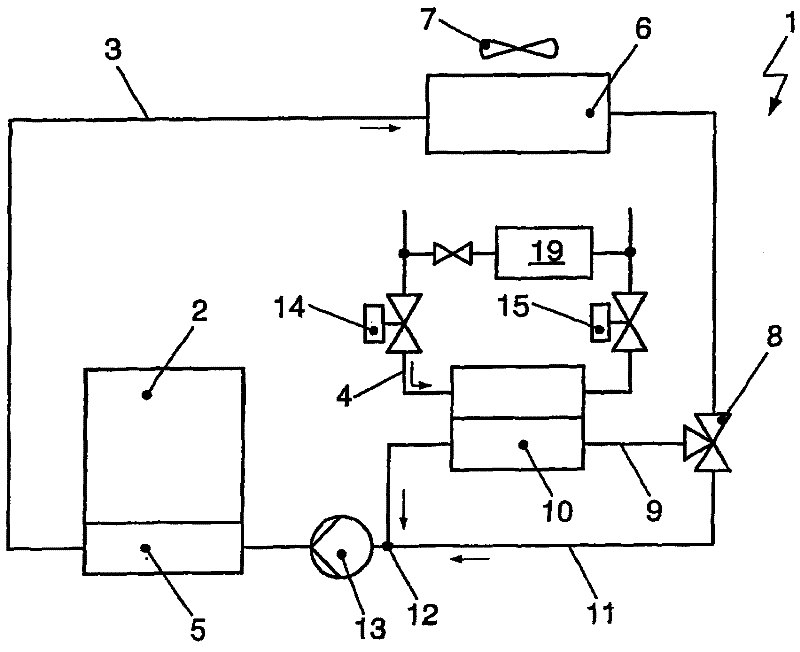

[0055] figure 1 It shows a cooling device 1 with a coolant circuit 3 which is designed to cool or dissipate the chemical energy store 2 . Instead of energy store 2 , also referred to below as battery 2 , other components of the drive train of the motor vehicle, such as an electric motor or power electronics, can likewise be coupled thermally to cooling device 1 .

[0056] The coolant circuit 3 has a pump device 13 for conveying coolant. Next to the coolant pump 13 in the direction of flow of the coolant is a heat transmitter 5 which is thermally coupled to the battery 2 . Various heat transfer methods are conceivable for this. The coolant either flows directly through the interstices formed between the battery cells and thus comes into direct contact with the surfaces of the battery cells. Alternatively, heat is transferred to the coolant via the contact surface of the housing of the accumulator 2 .

[0057] Following the battery cooler 5 in the flow direction of the coola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com