Gas-solid mixing accelerating chamber

A technology of gas-solid mixing and acceleration chamber, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials. Ratio, prevention of accumulation and clogging, and effect of preventing bottom accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

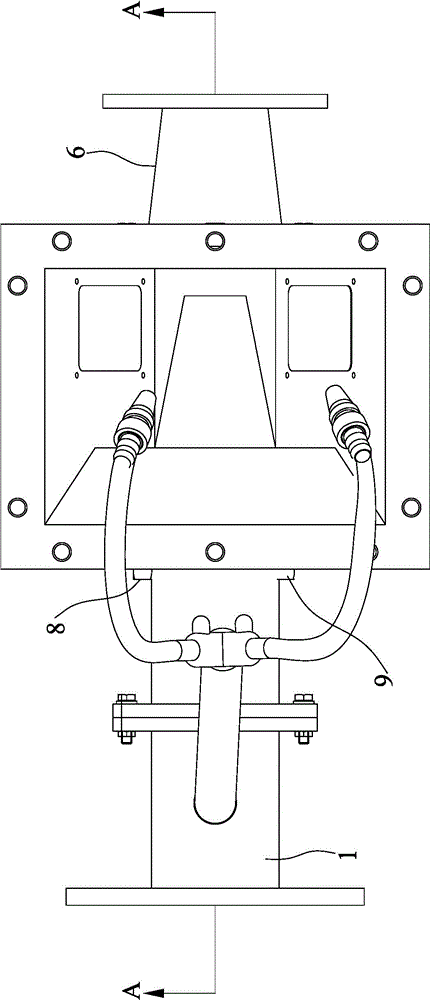

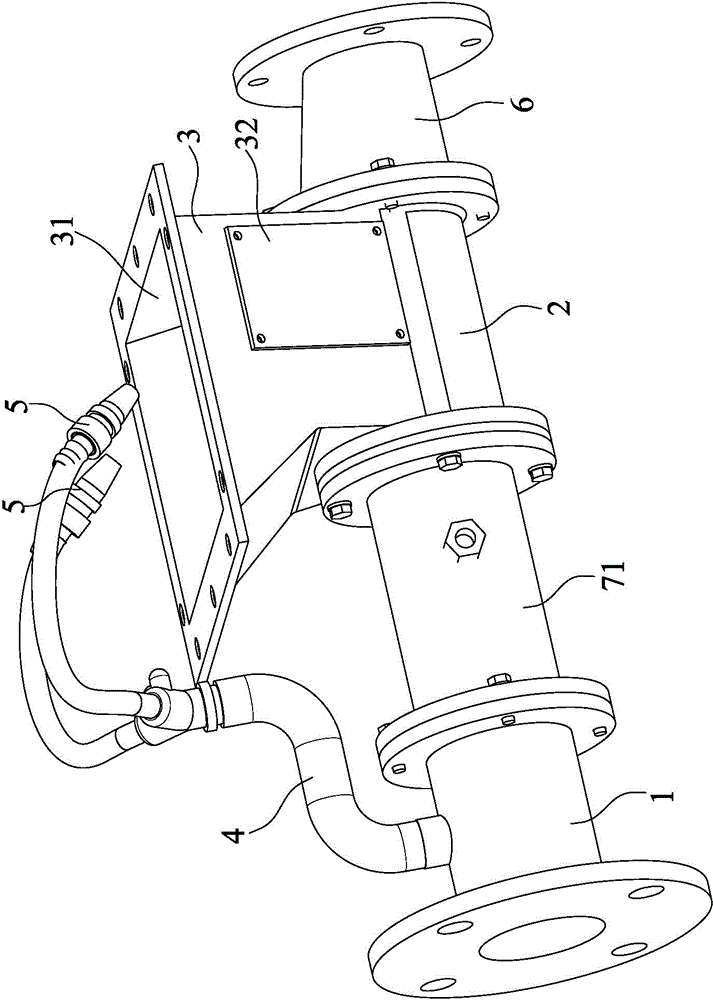

[0035] refer to Figure 1 to Figure 4 As shown, a gas-solid mixing acceleration chamber disclosed in the present invention includes a main inlet pipe 1 , a main nozzle 2 , a gas-solid mixing chamber 3 , branch pipes 4 , anti-blocking nozzles 5 and secondary nozzles 6 .

[0036] The main intake pipe 1 communicates with the main nozzle 2, the main nozzle 2 communicates with the gas-solid mixing chamber 3, the gas-solid mixing chamber 3 communicates with the secondary nozzle 6, and the secondary nozzle 6 communicates with the delivery pipeline (not shown in the figure). The structure of the main nozzle 2 is preferably an eccentric reducer structure (eccentric reducer structure, wherein the reducer is a tube with a large head gradually shrinking to a small head, also called a small head; when the eccentric reducer is erected, the projection of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com