Braking structure of reel

A wire reel and brake lever technology, which is applied in the field of brake structure, can solve the problems of large impact force, easy to be damaged, and noise, and achieve the effects of reducing impact force, preventing brake failure, and improving simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

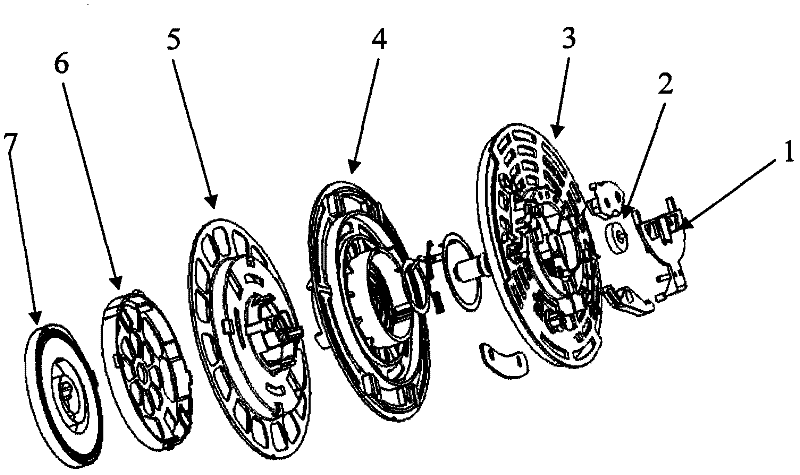

[0034] figure 1 It is a three-dimensional structure schematic diagram of the cord reel of the present invention. Such as figure 1As shown, the cable reel of the present invention includes a brake lever 1, a rubber wheel 2, a rear panel 3, an inner hub 4, an outer hub 5, a spring fixing plate 6 and a scroll spring 7, and the above-mentioned components are installed together in sequence. The inner hub 4 and the outer hub 5 constitute a part of the wire wheel assembly, which are used for winding the cable. When the brake structure of the cable reel of the present invention is in the braking state, the cable can be pulled out from the wire wheel assembly in one direction. At this time, the scroll spring 7 stores force through the spring fixing plate 6; In the normal state, the elastic force accumulated in the scroll spring 7 is released, and the cable is collected into the wire wheel assembly.

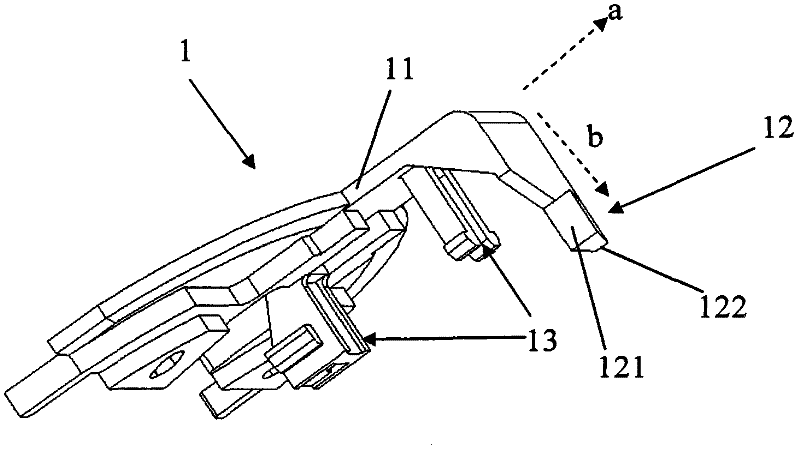

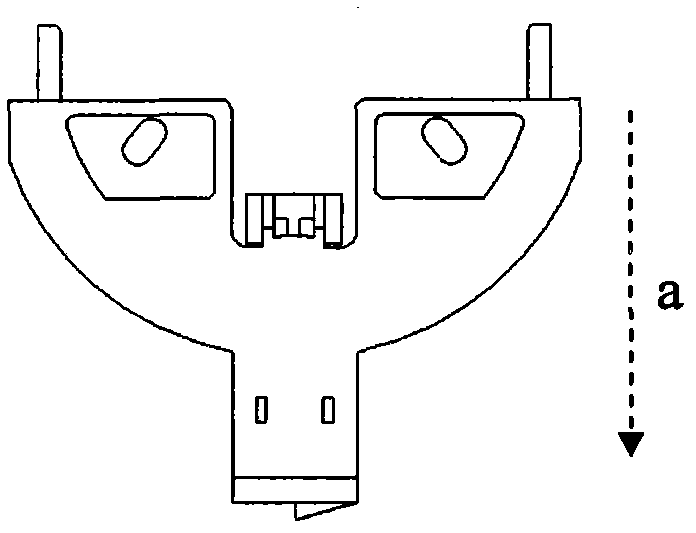

[0035] figure 2 yes figure 1 Schematic diagram of the structure of the brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com