Method for treating organic wastewater through dynamic membrane anaerobic-aerobic integration

A technology of organic wastewater and dynamic membrane, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of low efficiency, high investment cost, large equipment footprint, etc. problems, achieve the effect of increasing concentration, low investment cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

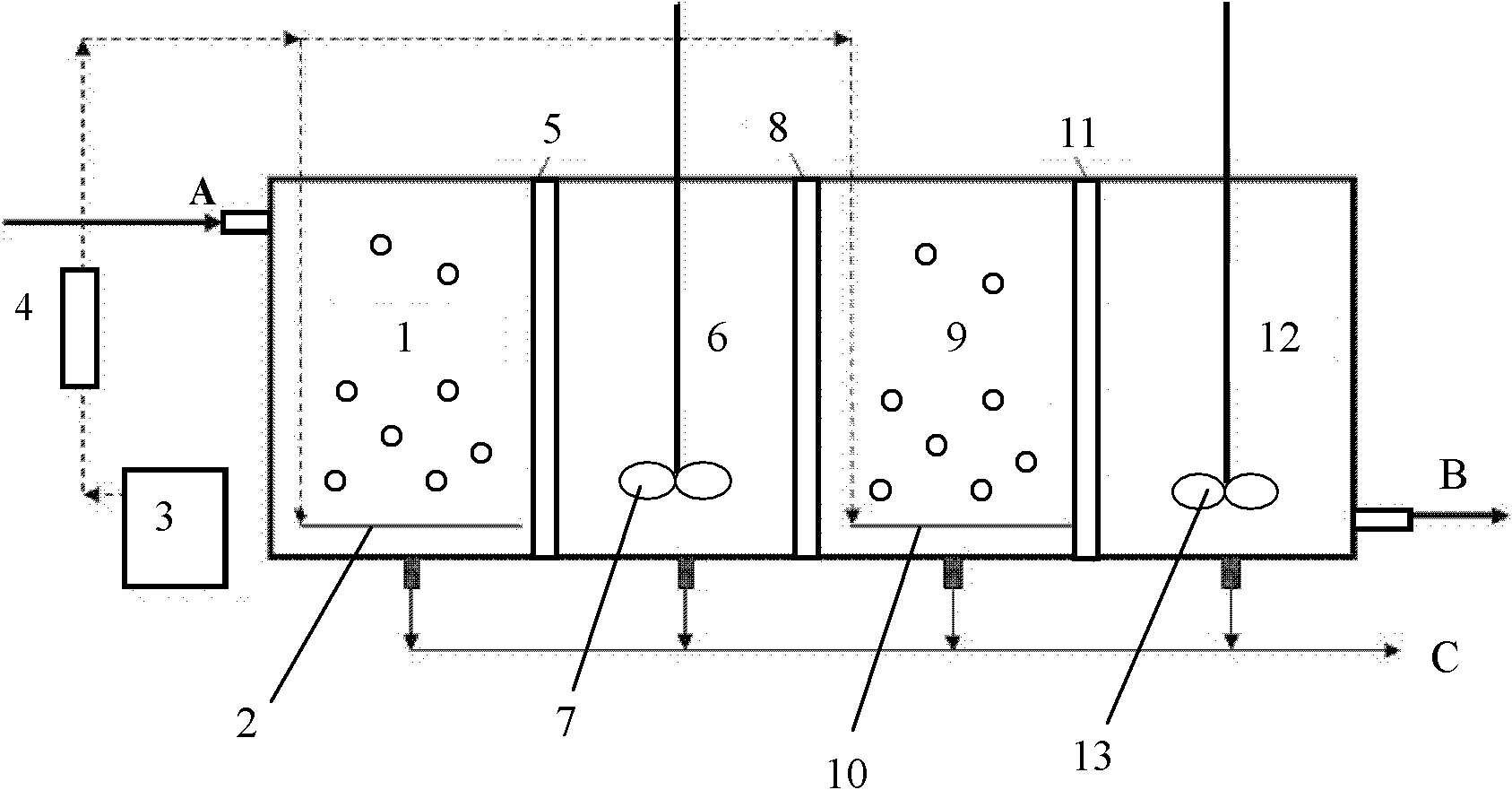

[0028] see figure 1 , the present invention comprises the following steps:

[0029] 1) The raw wastewater enters the first-level aerobic tank 1 through the water inlet A, and the first-level perforated aeration tube 2 is installed inside the first-level aerobic tank 1, and the external air compressor 3 is blown and aerated to The rotameter 4 controls the aeration rate, and the sludge is discharged from the bottom of the first stage aerobic tank 1 (in figure 1 Indicated by the mark C); the first-stage aerobic pool 1 can operate at a temperature of 10-35°C; the aeration rate can be controlled at 0.5-5L / min, and the first-stage aerobic pool 1 The dissolved oxygen can be DO≥2.0mg / L.

[0030] 2) The waste water treated by the first-stage aerobic pool 1 flows into the first-stage anaerobic pool 6 through the first-stage dynamic membrane 5, and the first-stage stirring device 7 is set in the first-stage anaerobic pool 6. Level 6 bottom sludge discharge of anaerobic tank (in figur...

Embodiment 2

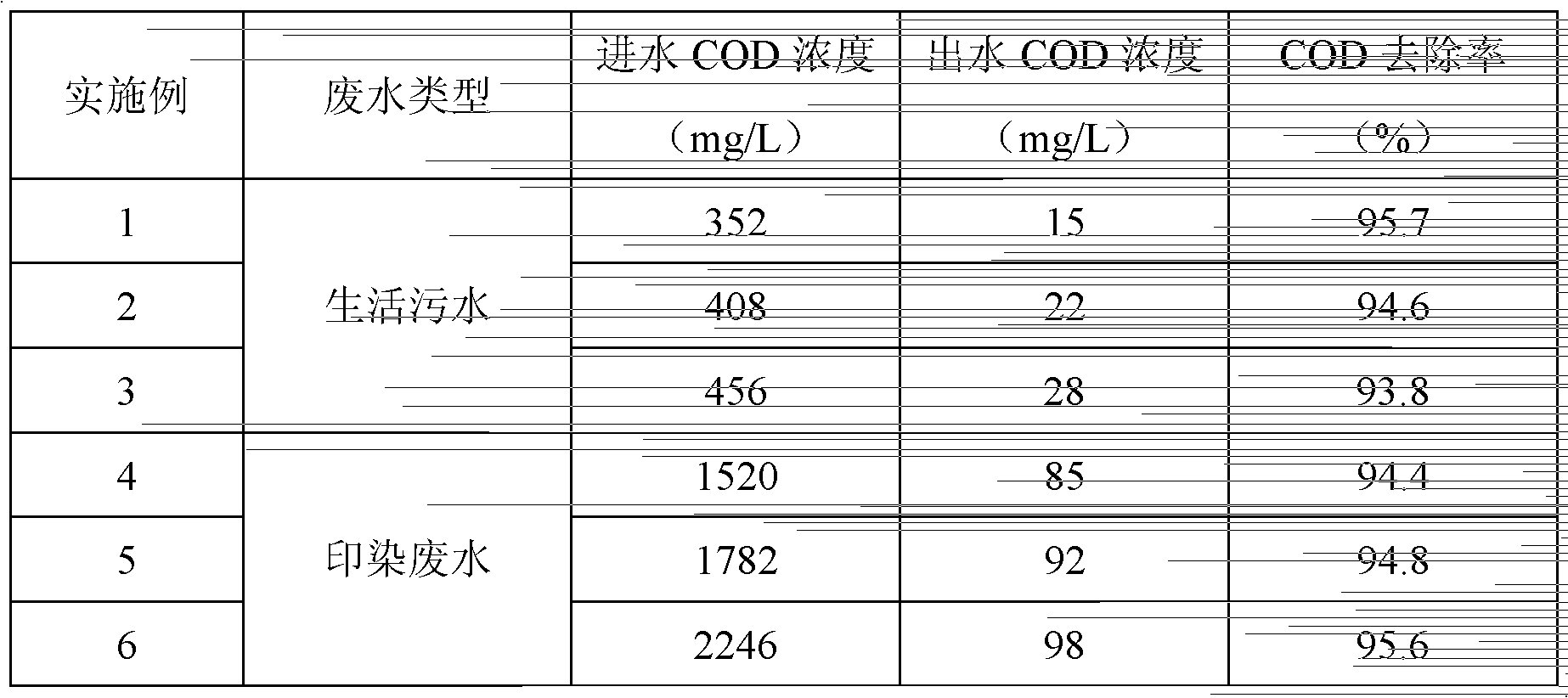

[0037] Similar to Example 1, the difference is that the influent COD concentration is 408 mg / L, and according to the influent organic load, the domestic sewage is successively distributed in the first-stage aerobic pool 1, the first-stage dynamic membrane 5, and the first-stage anaerobic pool 6. The second-level dynamic membrane 8, the second-level aerobic tank 9, the third-level dynamic membrane 11 and the second-level anaerobic tank 12 are biodegraded, and the COD, SS, and DO of the water in each pool are measured at different degradation times , pH value, temperature and other indicators, among which the COD concentration in the effluent is 22mg / L, and the COD removal rate is 94.6%.

Embodiment 3

[0039] Similar to Example 1, the difference is that the influent COD concentration is 456mg / L. According to the organic load of influent, the domestic sewage is sequentially distributed in the first-stage aerobic pool 1, the first-stage dynamic membrane 5, and the first-stage anaerobic pool. 6. The second-level dynamic membrane 8, the second-level aerobic tank 9, the third-level dynamic membrane 11 and the second-level anaerobic tank 12 are biodegraded, and the COD, SS, and DO of the water in each pool are measured at different degradation times , pH value, temperature and other indicators, among which the concentration of COD in the effluent is 28mg / L, and the removal rate of COD is 93.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com