Hot dip aluminum plating method for steel structure member

A technology for hot-dip aluminum plating and structural parts, applied in hot-dip plating process, coating, metal material coating process, etc. And the influence of personnel, the effect of reducing the amount of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The hot-dip aluminum plating method of the present invention is applied to the column pipe of the expressway.

[0038] Prepare the aluminum plating pot and the molten flux heating pot, put the corresponding materials in the pot respectively, and heat them to a molten state.

[0039] Dimensions of aluminized pot: inner diameter 1m* wall thickness 0.05m* depth 2.5m, containing 53 tons of aluminum, melted in about 24 hours.

[0040] Dimensions of molten flux heating pot: inner diameter 1m*depth 2.5m, containing 48 tons of molten flux.

[0041] The method of hot-dip aluminum plating for expressway column pipes is as follows:

[0042] 1) Pre-treatment: Clean the column pipe of the expressway before degreasing, derusting and aluminum plating;

[0043] 2) Aqueous solution electroplating treatment: perform aqueous solution electroplating treatment on the cleaned column tube;

[0044] 3) Drying: Dry the column tube coated with the transition aid;

[0045] 4) Flux treatment: ...

Embodiment 2

[0050] The hot-dip aluminizing method of the invention is applied to the corrugated guardrail beams of expressways.

[0051] According to the size of the plated parts, prepare the aluminum plating pot and the molten flux heating pot, put the corresponding materials in the pot respectively, and heat them to the molten state.

[0052] The hot-dip aluminum plating method for the corrugated guardrail beam of the expressway is as follows:

[0053] 1) Pre-treatment: Clean the highway guardrail beams before degreasing, derusting and aluminum plating;

[0054] 2) Aqueous solution electroplating treatment: perform aqueous solution electroplating treatment on the cleaned guardrail beam;

[0055] 3) Drying: Dry the guardrail beams coated with the crossing aid;

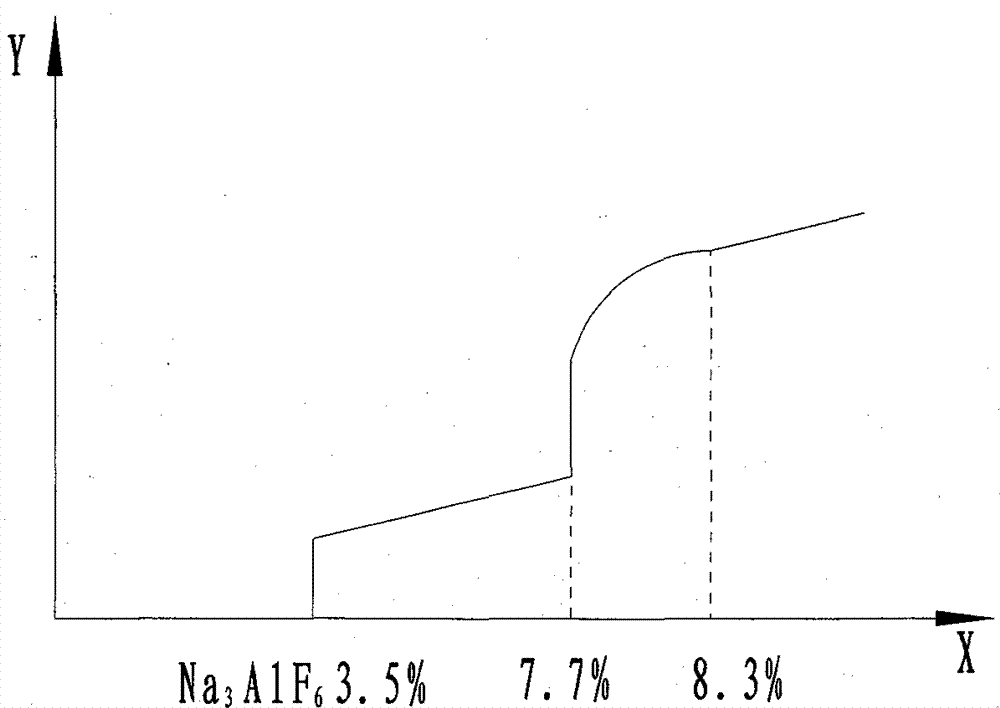

[0056] 4) Flux treatment: the mass percentage is 52% KCl, 42% NaCl, 3% Na 3 AlF 6 and 3% AlF 3 Throw it into the molten flux heating pot, and then add ZnCl which accounts for 5% of the sum of the above four substances in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com