Wool yarn looping auxiliary device of circular knitting loom and wool top knitting loom provided with the wool yarn looping auxiliary device

An auxiliary device, the technology of a circular knitting machine, which is applied to a circular machine for weft knitting with a single action needle, knitting, weft knitting, etc., which can solve problems such as unstable hooking and yarn not being hooked by the upper knitting needle , to achieve stable performance, ensure stability and operability, and control position accurately, uniformly and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

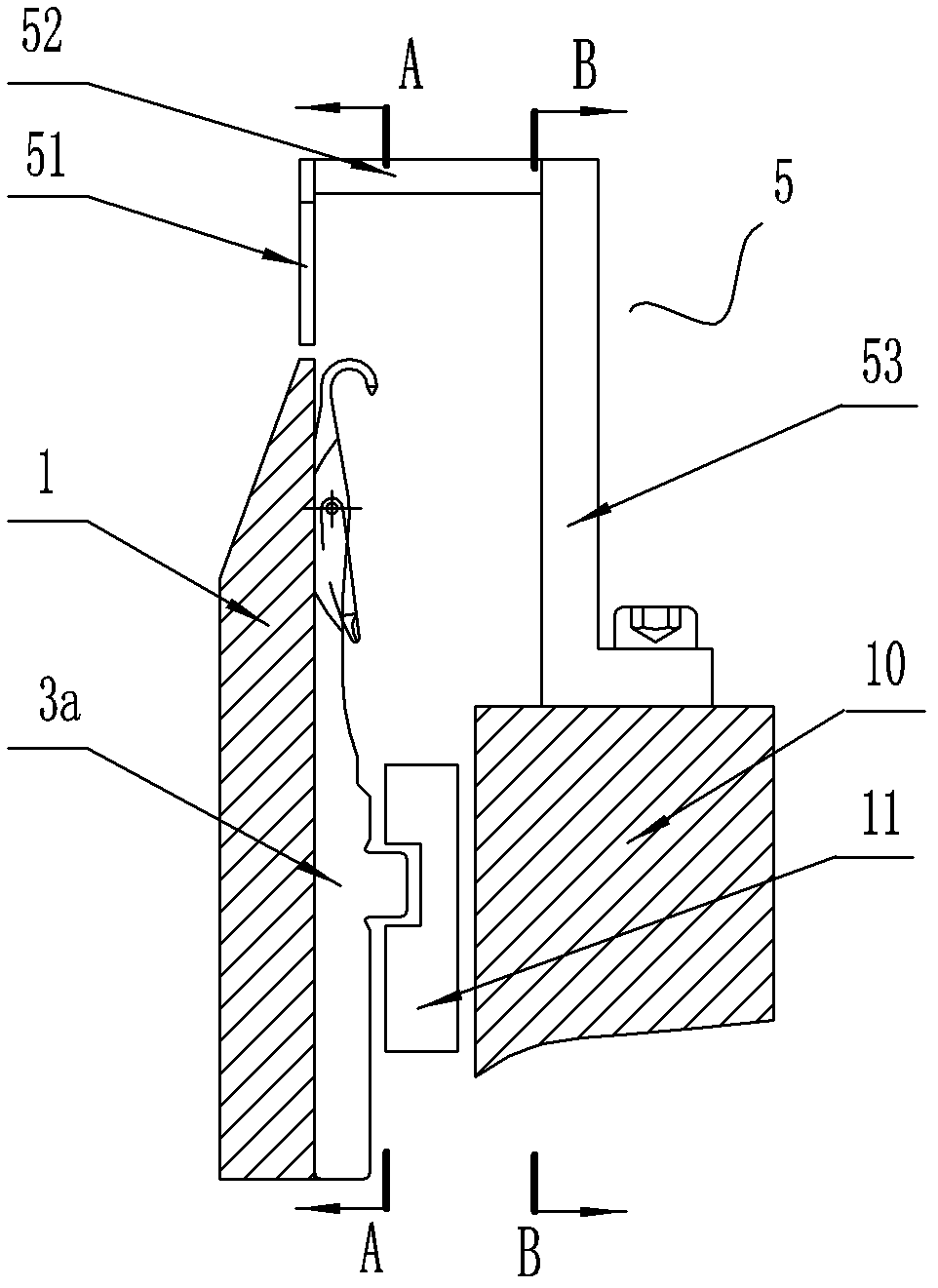

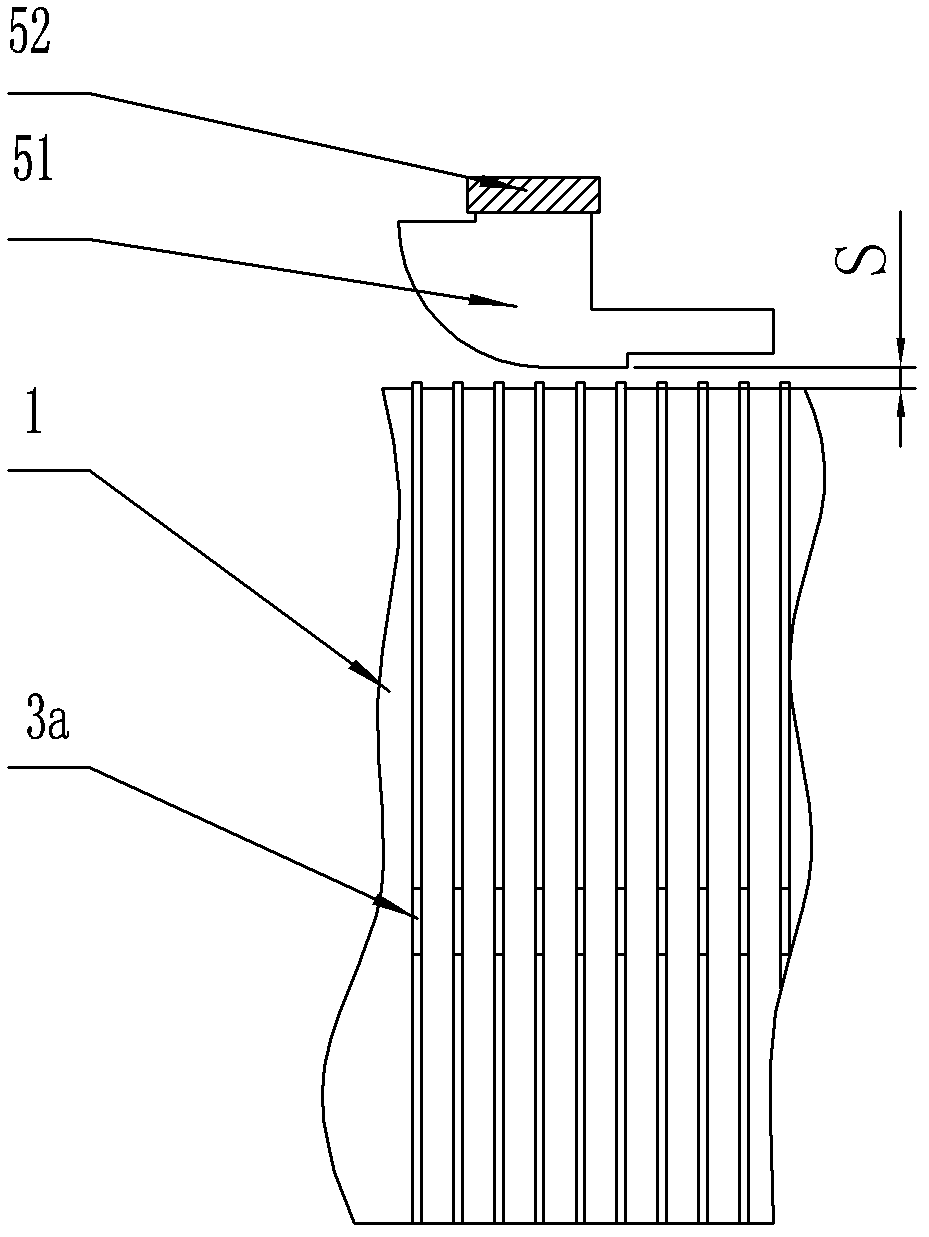

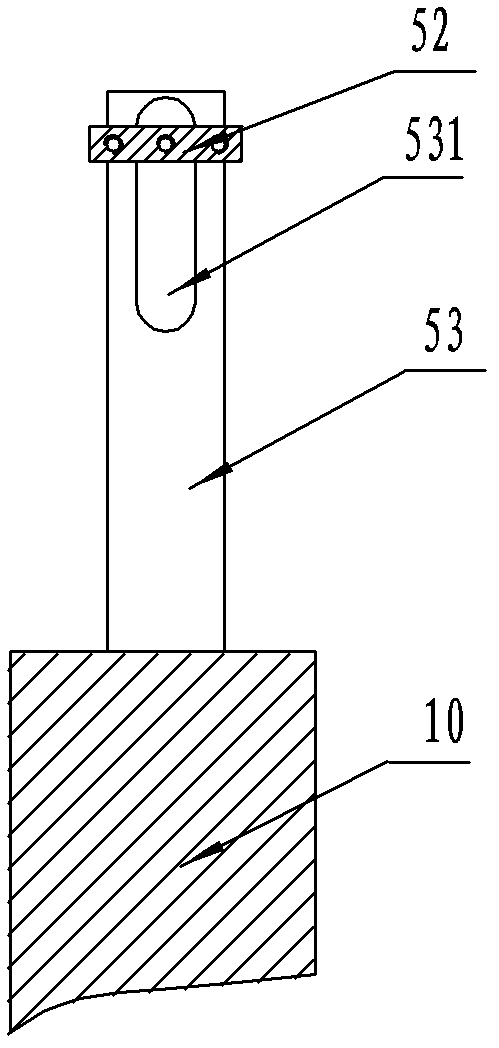

[0051] An auxiliary device for knitting wool yarn on a circular knitting machine, comprising a wool yarn knitting auxiliary plate 51, a position adjustment block 52 for the wool yarn knitting auxiliary plate and an adjustment seat 53 (see Figure 1-1 to Figure 1-3 );

[0052] The wool yarn knitting auxiliary plate 51 is an irregular polygonal plate similar to a knife. Knife handle, screw holes are arranged on the wool yarn looping auxiliary plate 51;

[0053] The position adjustment block 52 of the wool yarn knitting auxiliary plate is a strip-shaped plate with a rectangular cross section, and screw holes are arranged on it;

[0054] The adjustment seat 53 is an L-shaped plate with a rectangular cross section, and a strip-shaped hole 531 is arranged on the vertical edge of the L-shaped plate;

[0055] In use, the wool yarn loop forming auxiliary plate 51 is located outside the mouth of the upper needle cylinder 9, on the back of the crochet needles and vertically above the m...

Embodiment 2

[0057] A top knitting machine with an auxiliary device for knitting wool yarn on a circular knitting machine, such as Figure 2-1~Figure 2-2 As shown, the top knitting machine includes an upper needle cylinder 9 with needle grooves on it, a lower needle cylinder 1, upper knitting needles 6, 7 positioned in the needle grooves of the upper needle cylinder and positive hooks positioned in the needle grooves of the lower needle cylinders. Knitting needles 3a, upper and lower triangles; the top knitting machine also has a wool yarn looping auxiliary device 5, and the wool yarn looping auxiliary device 5 is the wool yarn looping auxiliary device of the circular knitting machine described in embodiment one ( see Figure 1-1 to Figure 1-3 ), the positive crochet needle 3a is a lower knitting needle with a latch, the hook direction and the stitches are on the same surface and in the same direction, and the back of the hook faces the center of the lower needle cylinder after being inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com