Three-dimensional fine modeling method oriented to immersed tube tunnel seismic design

An immersed tunnel and seismic design technology, applied in the field of underwater tunnel engineering, can solve problems such as the inability to simulate shear bonds and Gina waterstops, the inability to accurately calculate the spring-mass model, and the inability to simulate hydraulic crimping of immersed tunnels. , to achieve good engineering practicability and meet the effect of computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with the accompanying drawings and embodiments, based on the general finite element software ABAQUS, the specific implementation of the present invention will be further described in detail.

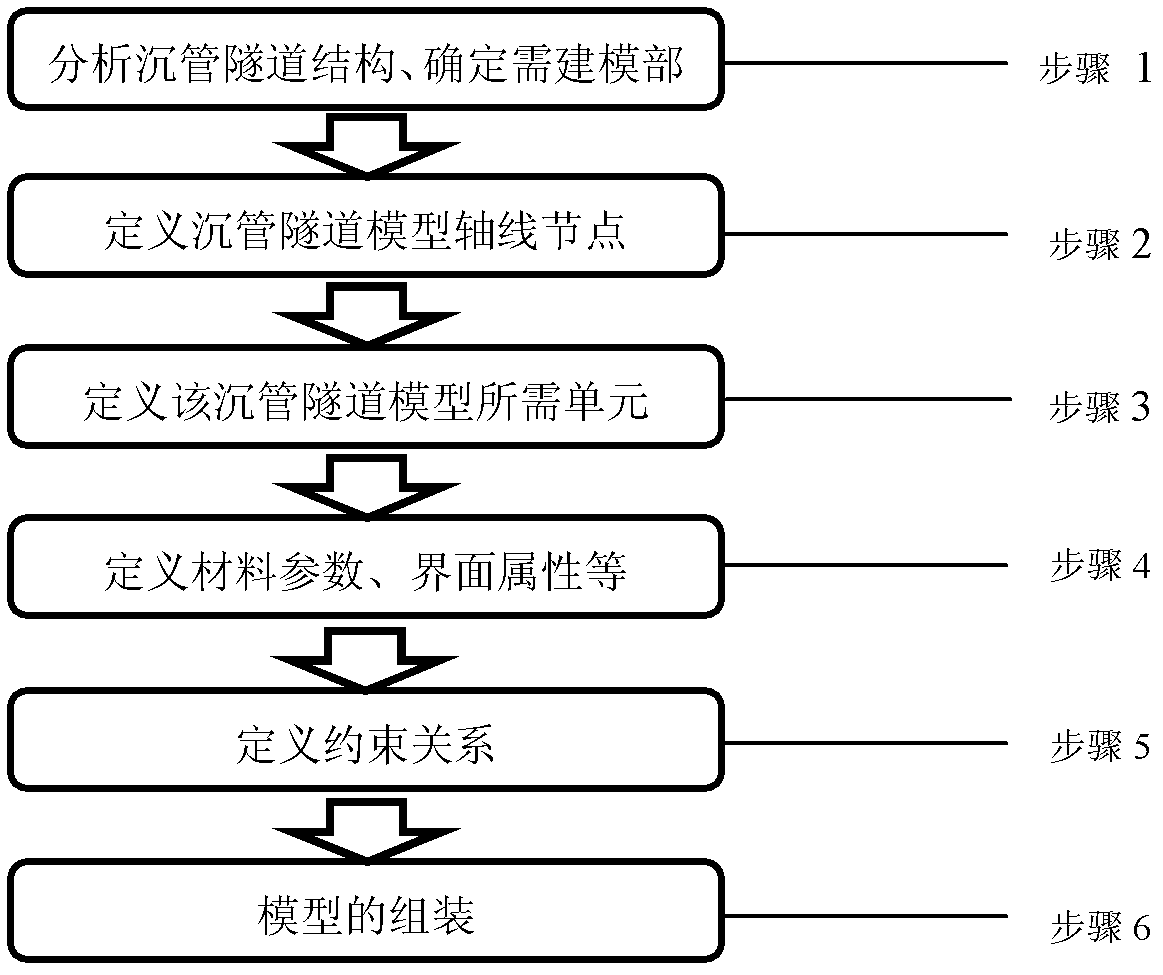

[0040] Step 1: Structural analysis of the tunnel structure to be designed, including: determining the geometric position of its axis, the buried depth of the tunnel, and the distribution of surrounding soil layers. The part of the tunnel to be constructed by the buried pipe segment method is taken as the modeling range.

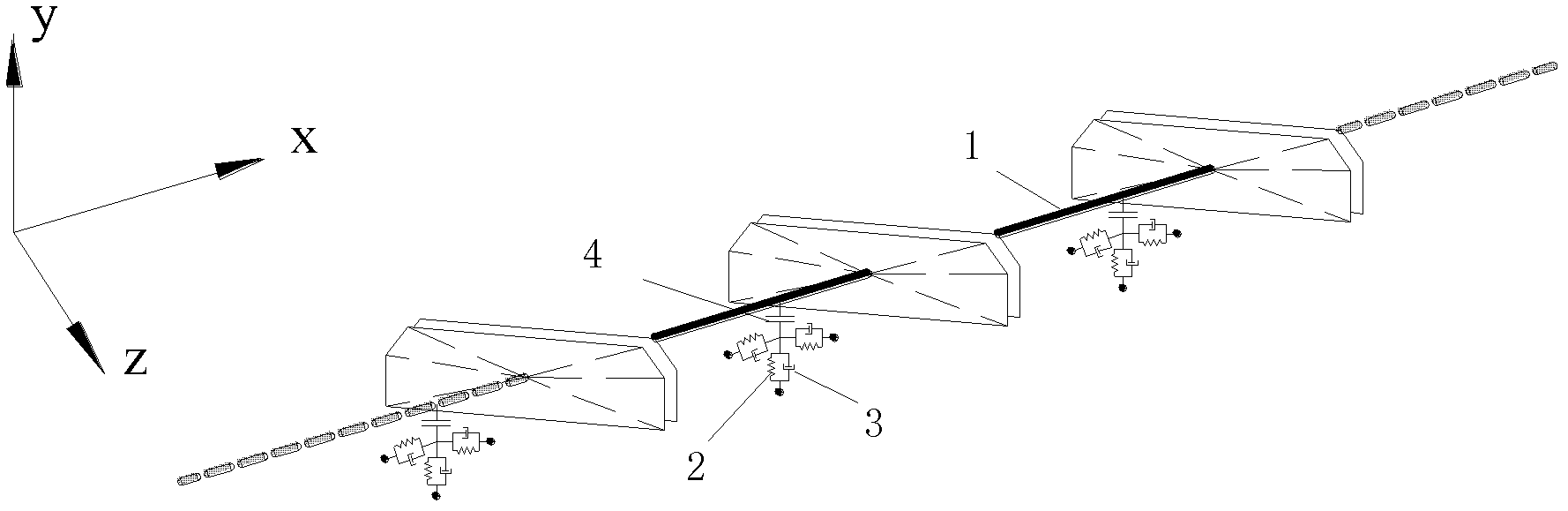

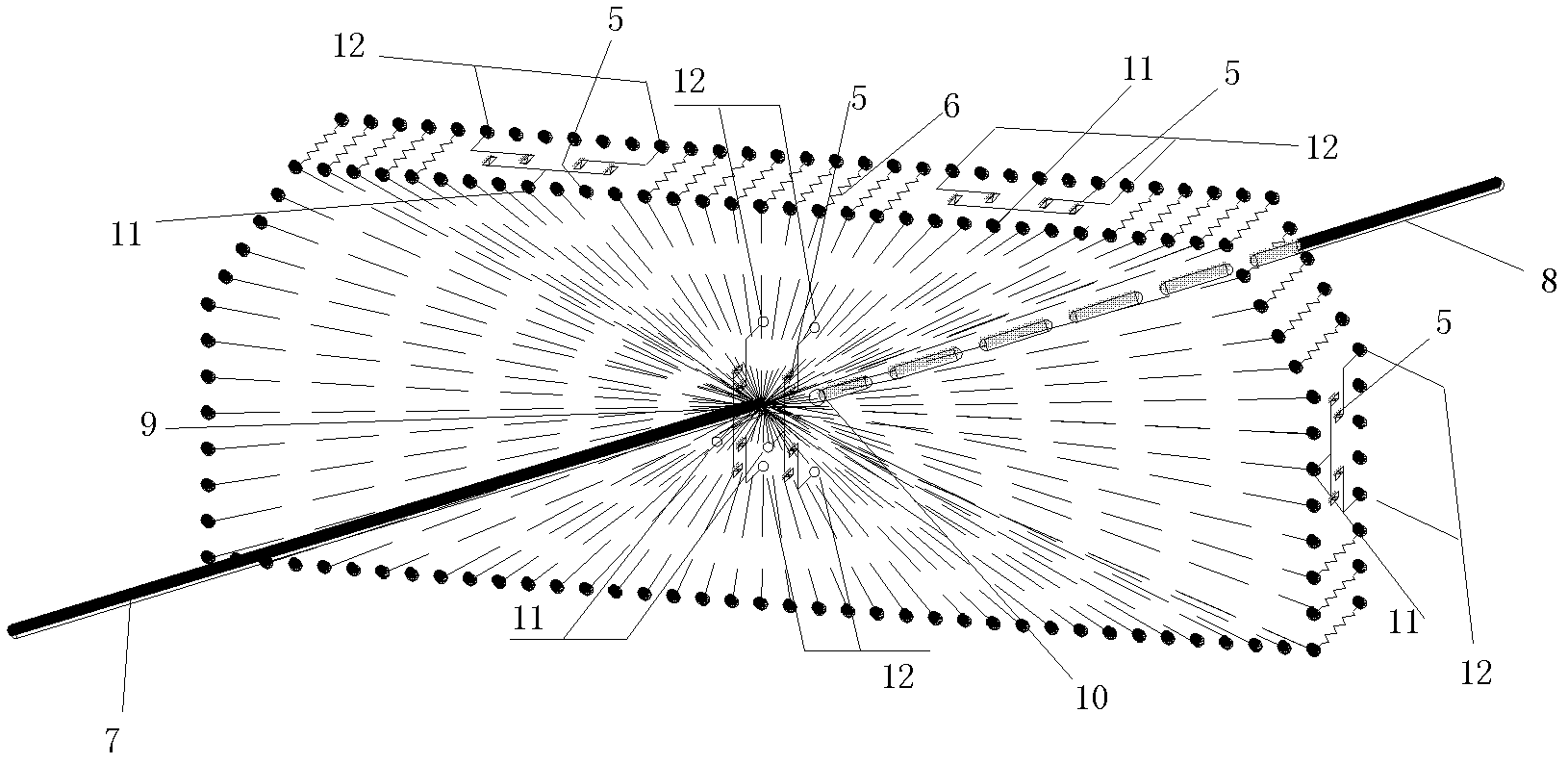

[0041] Such as figure 1 As shown, the immersed tunnel model includes pipe joint 1, foundation spring 2, sticky pot 3, sliding unit 4, shear key 5, Gina waterstop 6 and other parts.

[0042] Step 2, such as figure 1The control nodes that define the immersed tunnel model are shown. The control nodes include three parts: nodes on the axis of the pipe joint, nodes of the foundation spring and sticky pot used to simulate soil behavior, and node...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com