Automatic concentration adjusting and controlling early warning method for underground gas extraction pipelines and system of automatic concentration adjusting and controlling early warning method

A gas concentration and gas extraction technology, which is applied in the fields of gas concentration regulation and hidden danger warning in underground gas extraction pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

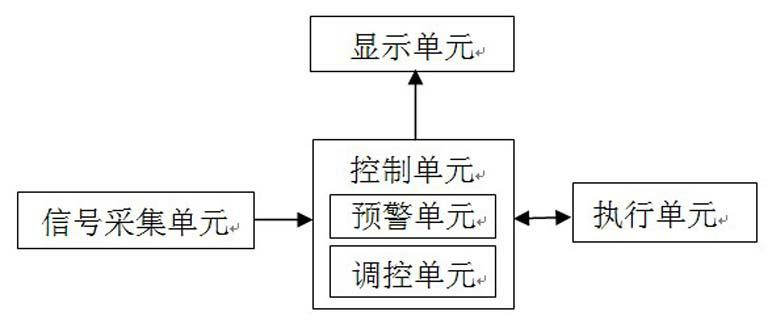

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

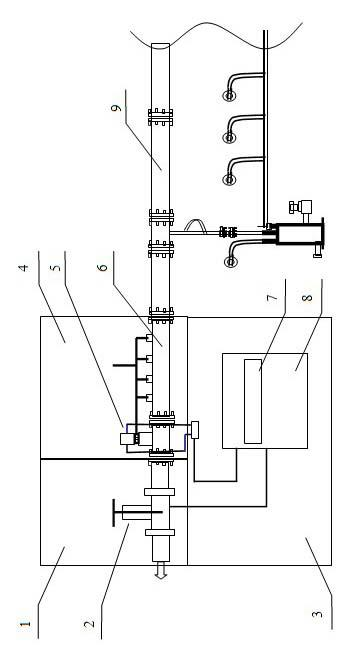

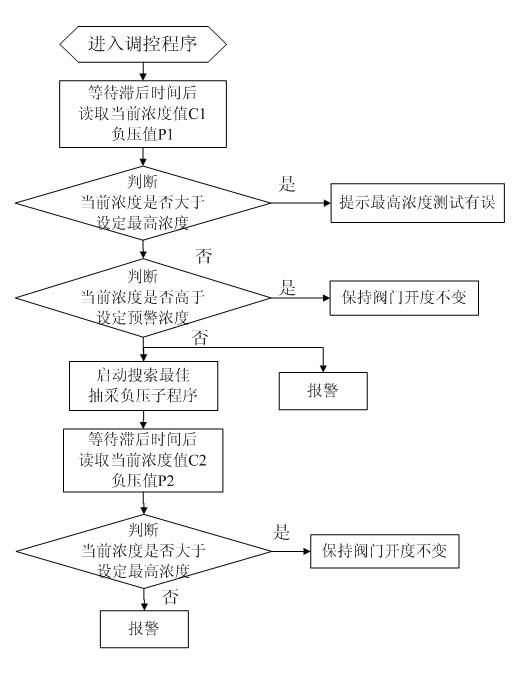

Embodiment Construction

[0032] Before designing the present invention, the following analysis and research were done: the relationship between the concentration of gas drainage and the negative pressure of gas drainage in different extraction stages is changing, and the requirements for the level of negative pressure are different in different stages, and there is a reasonable extraction Negative pressure. Such as Image 6 As shown, too high negative pressure at the initial stage of drainage will lead to a decrease in drainage concentration, and too low negative pressure in the middle period of drainage will also lead to a decrease in drainage concentration. Figure 7 As shown, the extraction concentration will decrease if the negative pressure is too high or too low, and there is a peak value of the extraction concentration. Based on the above findings, the present invention can automatically adjust pipeline drainage negative pressure at different drainage stages, stabilize gas drainage concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com