Bidirectional hydraulic buffer

A two-way hydraulic and buffer technology, used in liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of reduced stroke, simultaneous reset of piston rods, and inoperable buffers, reducing volume and simplifying structure. , the effect of length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical solution of the present invention clearer, the technical solution and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

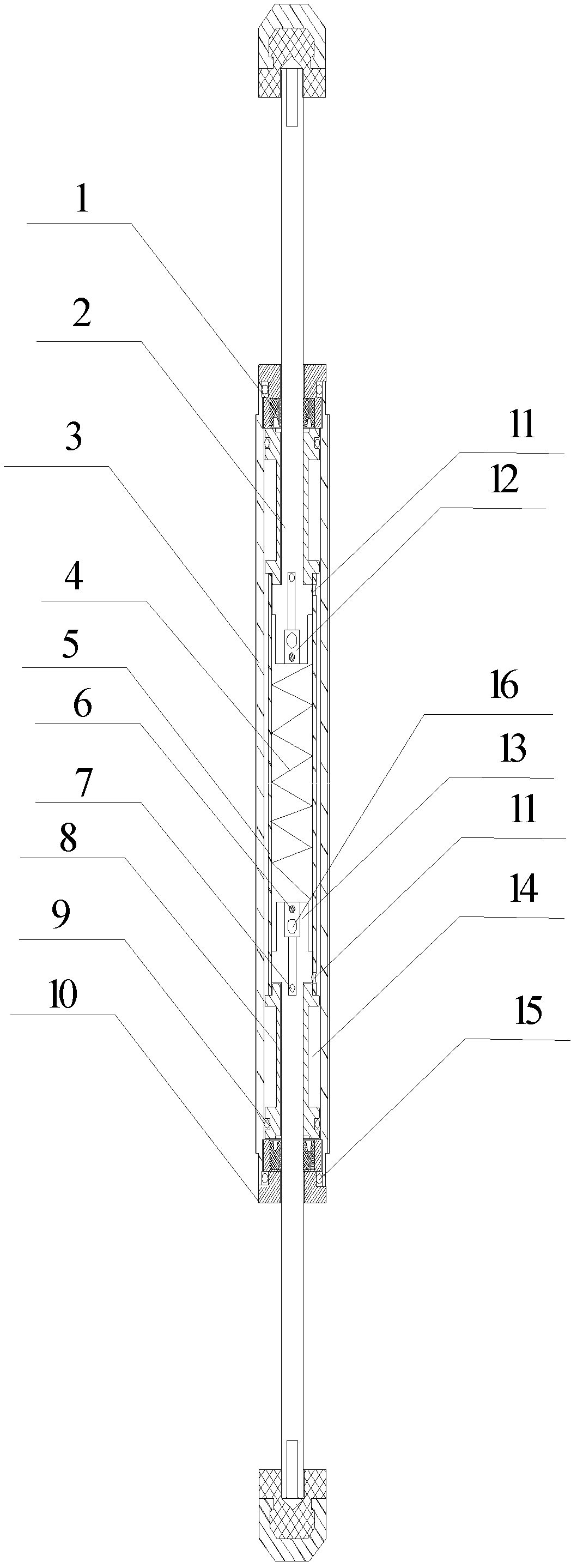

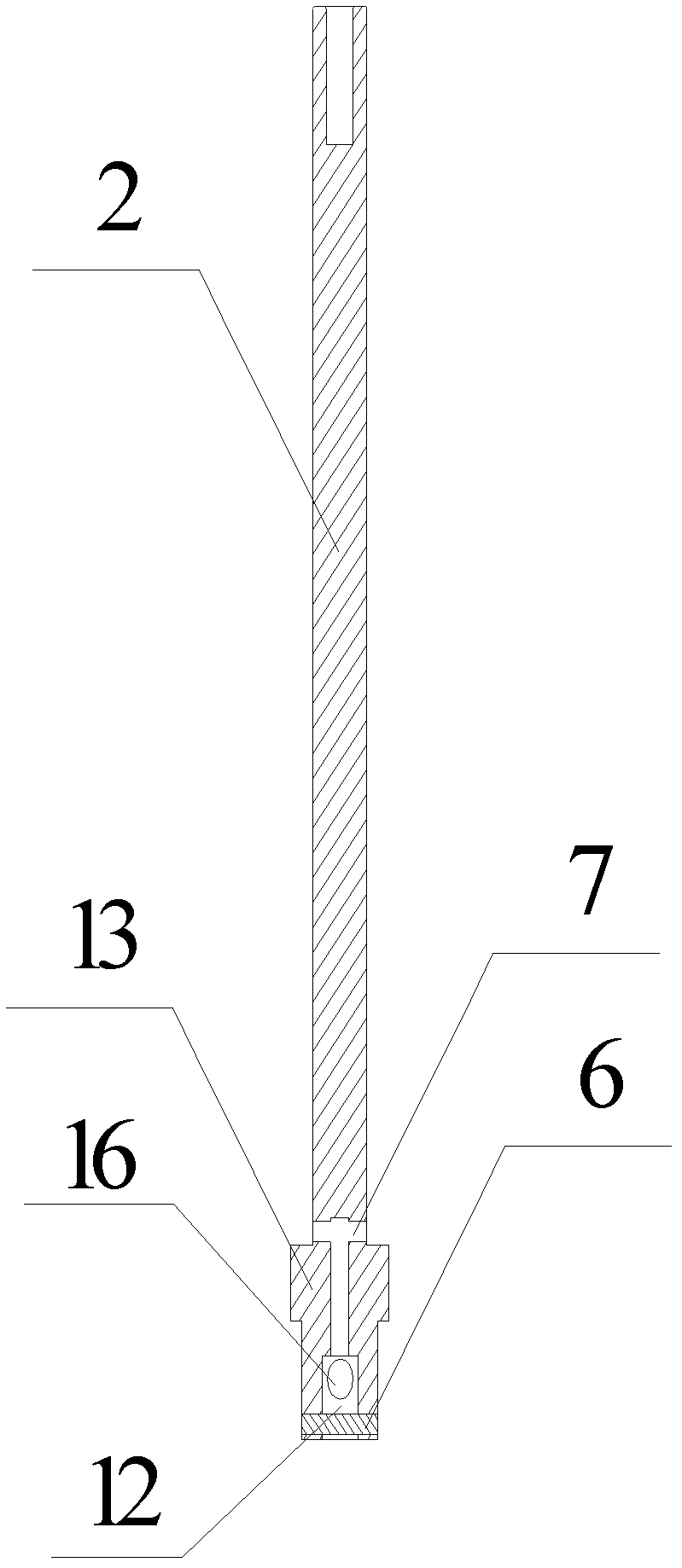

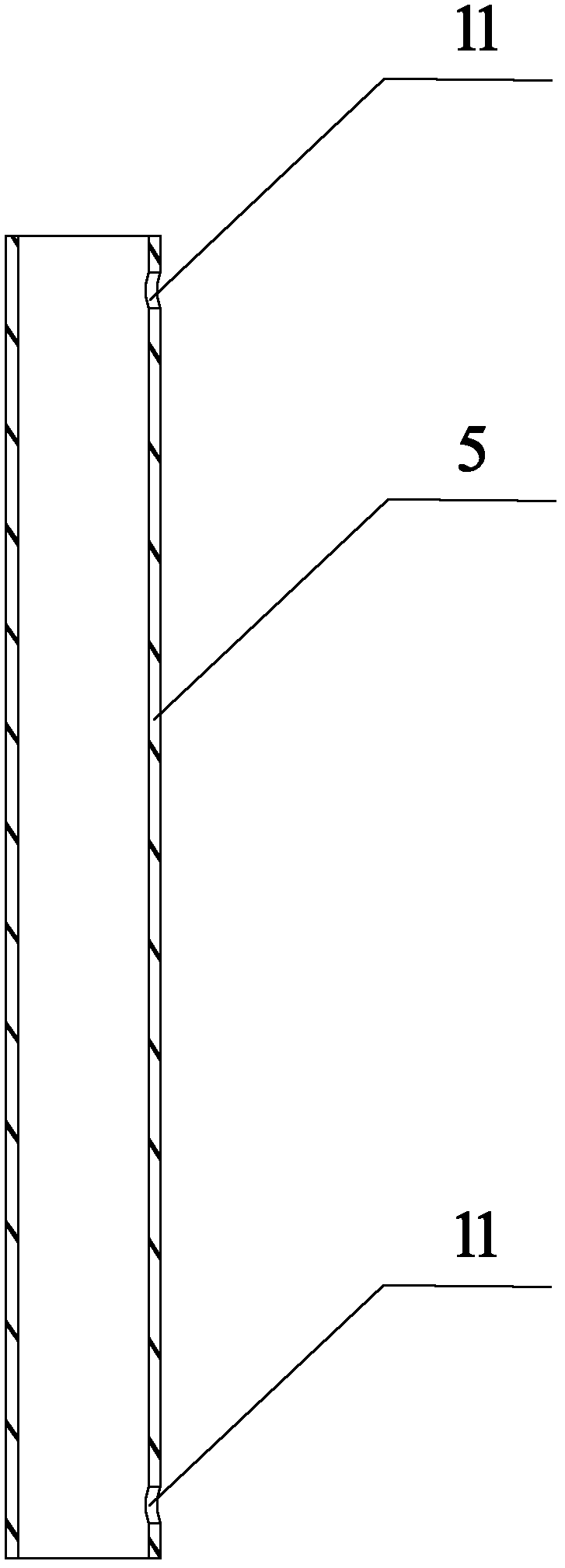

[0029] See attached Figures 1 to 3 , is a structural schematic diagram of an embodiment of the present invention. This embodiment adopts a hydraulic cylinder structure including an inner cylinder 5 and an outer cylinder 3. Under this structure, two pistons 13 are arranged in the inner cylinder 5, and two Piston connecting rod 2 is respectively connected with a piston 13, and a return spring 4 is arranged between the two pistons 13. When the buffer is working, one end receives the external impulse to perform buffering work, and at the same time compresses the return spring 4, and after the external impulse disappears, , the piston connecting rod 2 and the piston 13 return to their original positions under the action of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com