One-way transmission mechanism with double-acting continuous output

A one-way transmission, double-acting technology, applied in the direction of transmission, mechanical equipment, belt/chain/gear, etc., can solve the problem that the overrunning clutch has not been improved, and achieve high transmission capacity, high power, and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

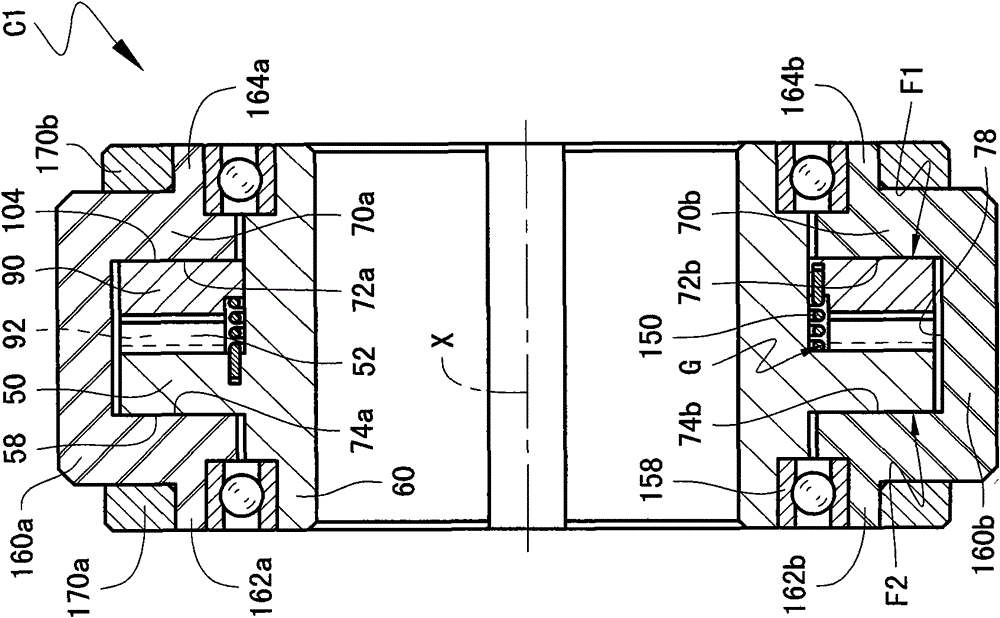

[0052] Embodiment 1: One-way transmission mechanism S1 with different shafts and two-way continuous action

[0053] Here, the one-way transmission mechanism S1 is specifically used as the output mechanism of the pulsating continuously variable transmission, but transmission mechanisms such as cranks, connecting rods, cams, or eccentrics, which are known technologies that do not involve the essence of the present invention, are omitted. and speed regulators, etc.

[0054] see image 3 , the output mechanism of the one-way transmission mechanism S1, including two forward-swing overrunning clutches C2 and anti-swing overrunning clutches C3 based on the space wedging friction overrunning clutch C1 with the same working / engagement direction. Wherein, the combination of the force limiting elements 160a and 160b of the clutch C2 is used as the positive pendulum input member 122, which is formed as a rigid body with the swing rod 100, on which a connecting rod 190 for obtaining input...

Embodiment 2

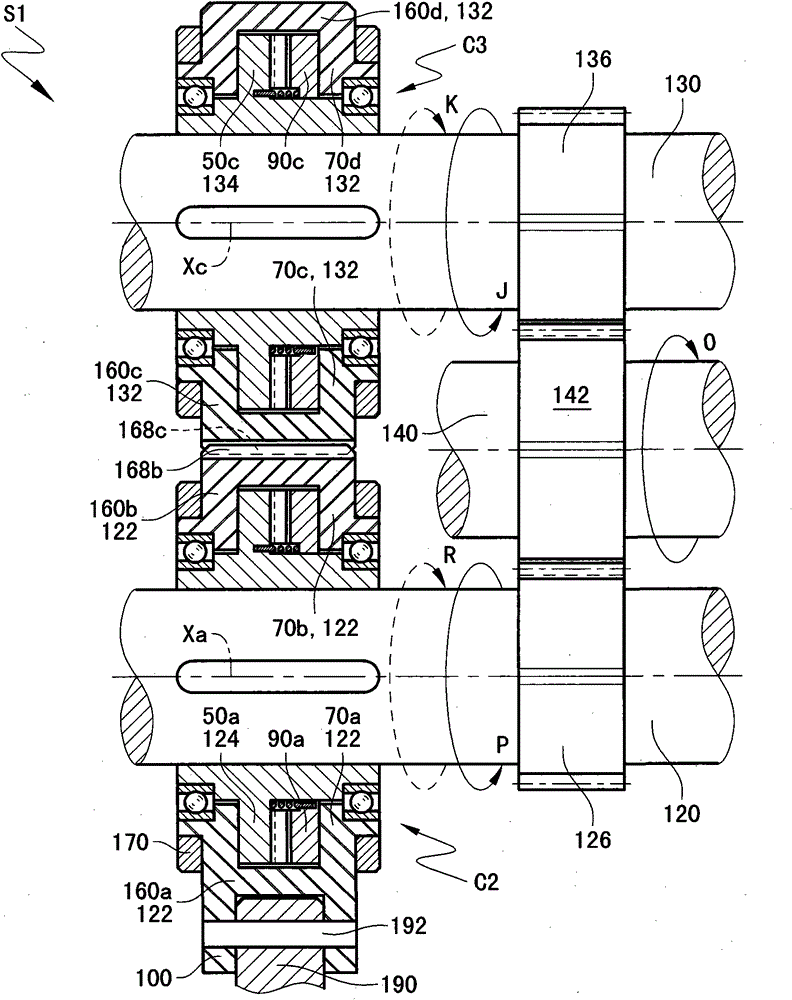

[0064] Embodiment 2: One-way transmission mechanism S2 of coaxial setting type two-way continuous action

[0065] see Figure 4 , the one-way transmission mechanism S2 can be regarded as a modification of the one-way transmission mechanism S1. Among them, the forward swing overrunning clutch C4 and reverse swing overrunning clutch C5 based on the space wedge friction overrunning clutch C1 are arranged on the same axis X. For this reason, the two clutches C4 and C5 have mutually opposite working directions and are optimally axially rigidly connected, that is, the positive swing input 122 and the reverse swing input 132 of the two are optimally rigidly integrated into a coaxial rotation The substantially annular pocket-shaped force limiting element 160. Obviously, the two can also be connected only non-rotatably, if desired. In order to realize the meshing connection between the anti-swing output member 134 and the anti-swing shaft 130 to output the anti-swing torque, the pre...

Embodiment 3

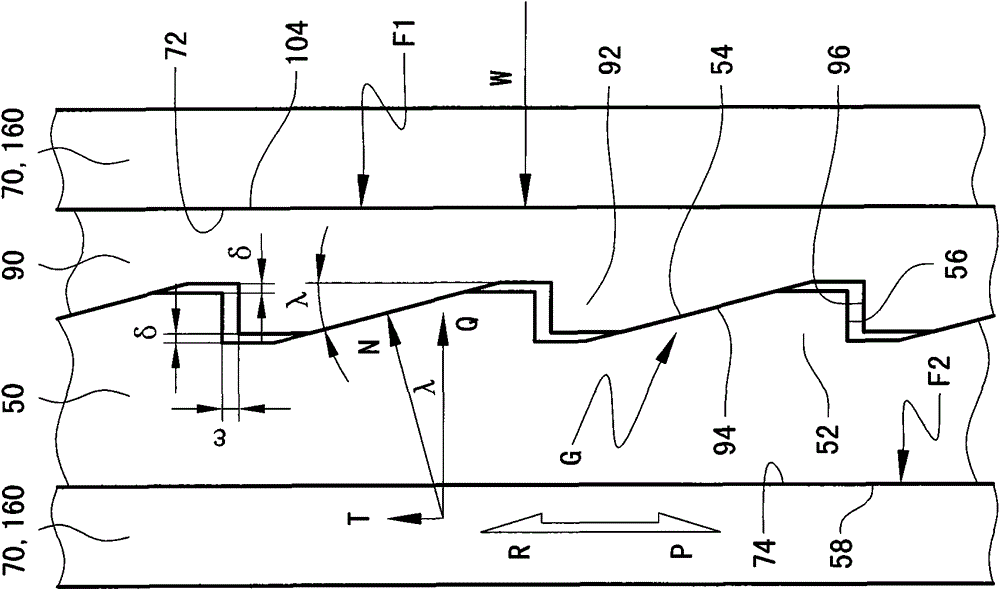

[0071] Embodiment 3: One-way transmission mechanism S3 of coaxial setting type two-way continuous action

[0072] The biggest difference between this embodiment and the preceding embodiments is only that it will figure 1 A set of helical guide teeth 52 and 92 in the shown overrunning clutch C1 are in the form of single or multiple helical teeth, and are continuously arranged on the inner or outer peripheral surfaces of the guide member 50 and the intermediary member 90 facing each other in the circumferential direction, respectively. , see Image 6 . The guide tooth may have a cross-sectional shape such as a rectangle, a trapezoid, a zigzag or a triangle. As a result, the overrunning clutches C6-C9 can automatically compensate for wear and have a stable slip angle during the entire life cycle, and at the same time, they can connect three completely symmetrical rings without fixed connection (forming a combined component). The components are configured in the simplest manne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com