Rotating part-supporting mechanism for lower mold of Transfer line

A rotary and mold technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unrealizable stamping direction and complicated parts, and achieve the effect of high-speed continuous production, compact structure and precise rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

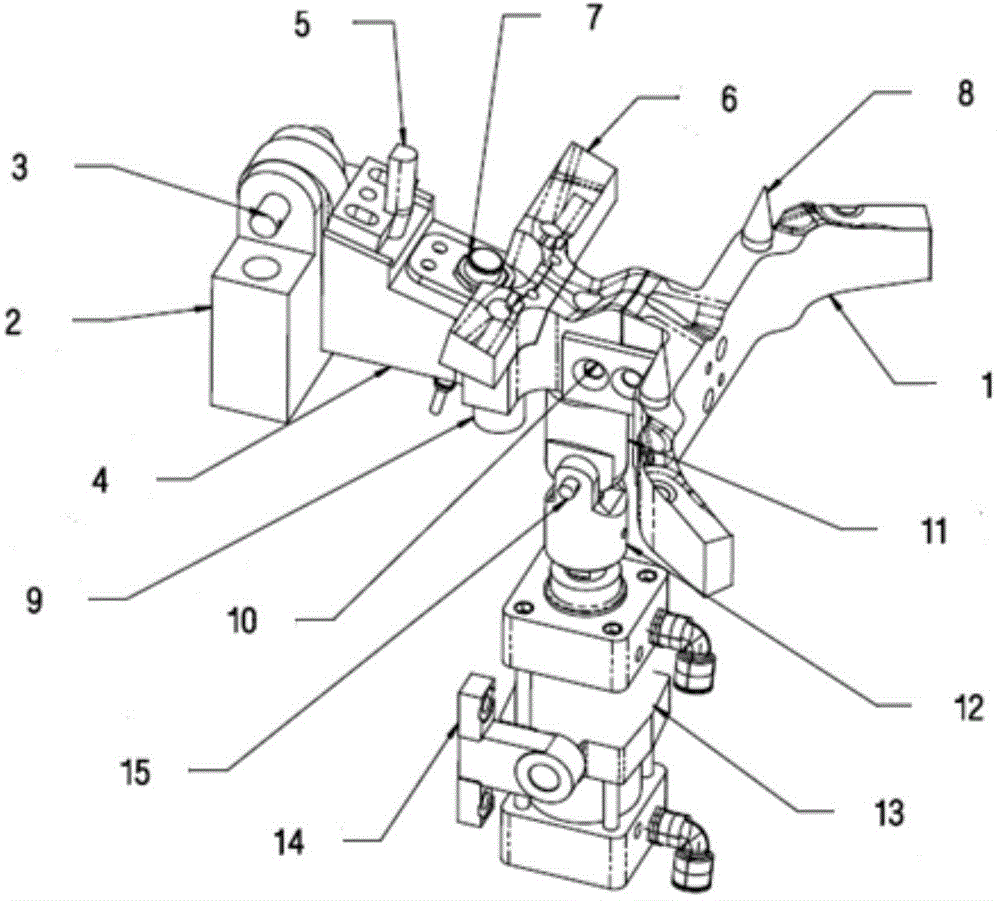

[0013] The concrete technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

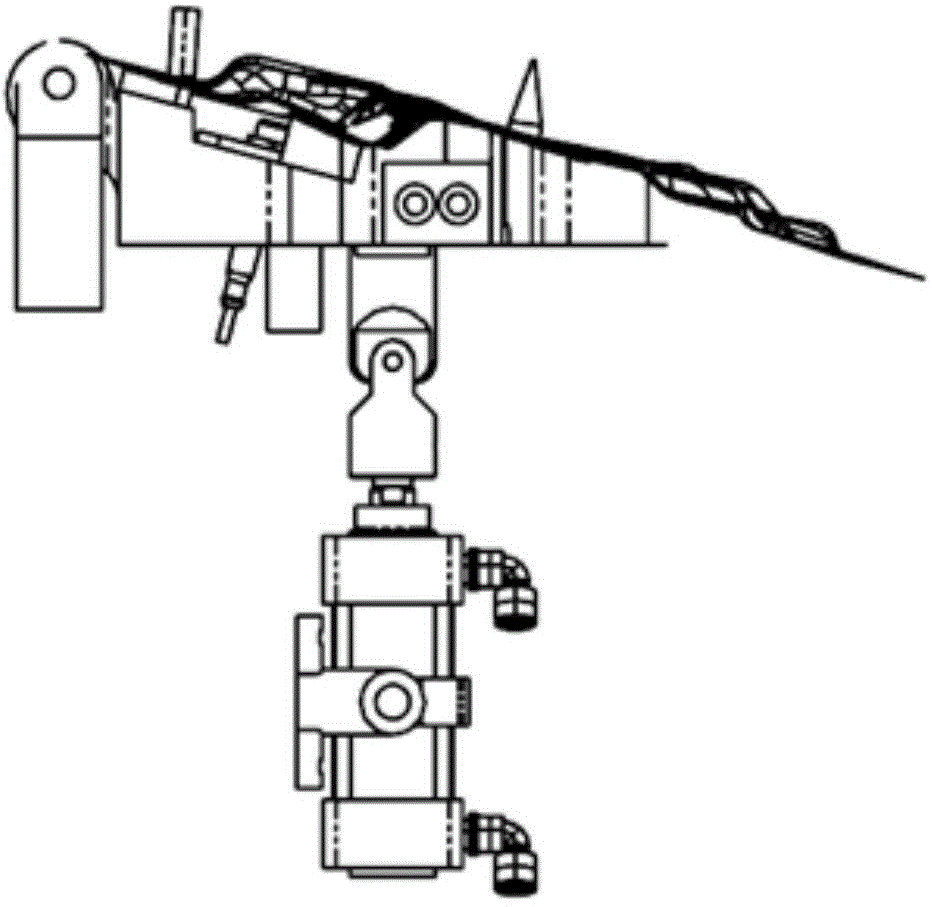

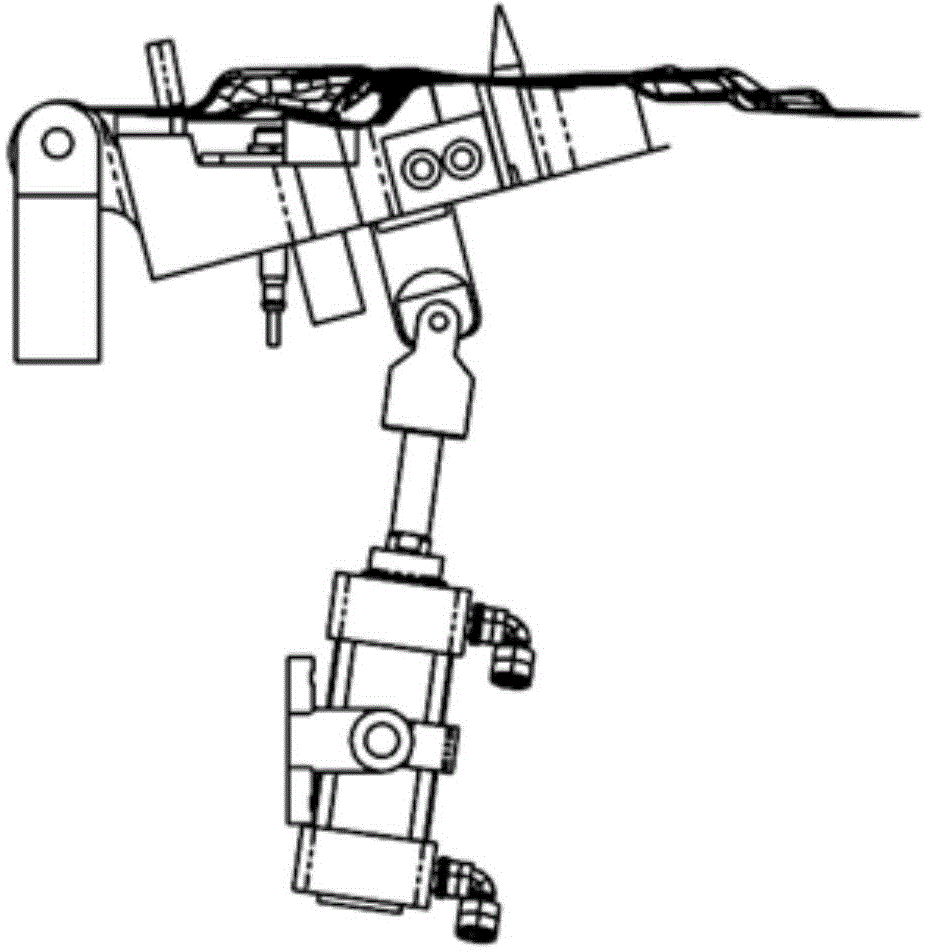

[0014] During the die stamping process of the Transfer line, the upper slider of the machine tool moves from the bottom dead point to the upper dead point, and the upper and lower dies of the die are gradually opened. figure 2 It is the position of the rotary support mechanism at the bottom dead center of the mold (stamping state). At this time, the Crossbar of the Transfer line drives the gripper to transfer the parts of this process to the next process with the same layout distance and pick-and-place height. After the part leaves, figure 1 The workpiece sensor 7 in the sensor senses the departure of the workpiece and sends an electronic signal to the machine tool. After the machine tool senses the electronic signal, the machine tool sends a pneumatic signal at the same time. figure 1 The middle cylinder 14 is pushed out under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com