an oil press

A technology for oil presses and oil plants, which is applied in the direction of presses and manufacturing tools, can solve the problems of screw extrusion wear of the screw shaft, easy blockage of the oil outlet hole of the press chamber, and difficult processing of the screw press, so as to reduce loss, Flexible use, reduce the effect of stalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

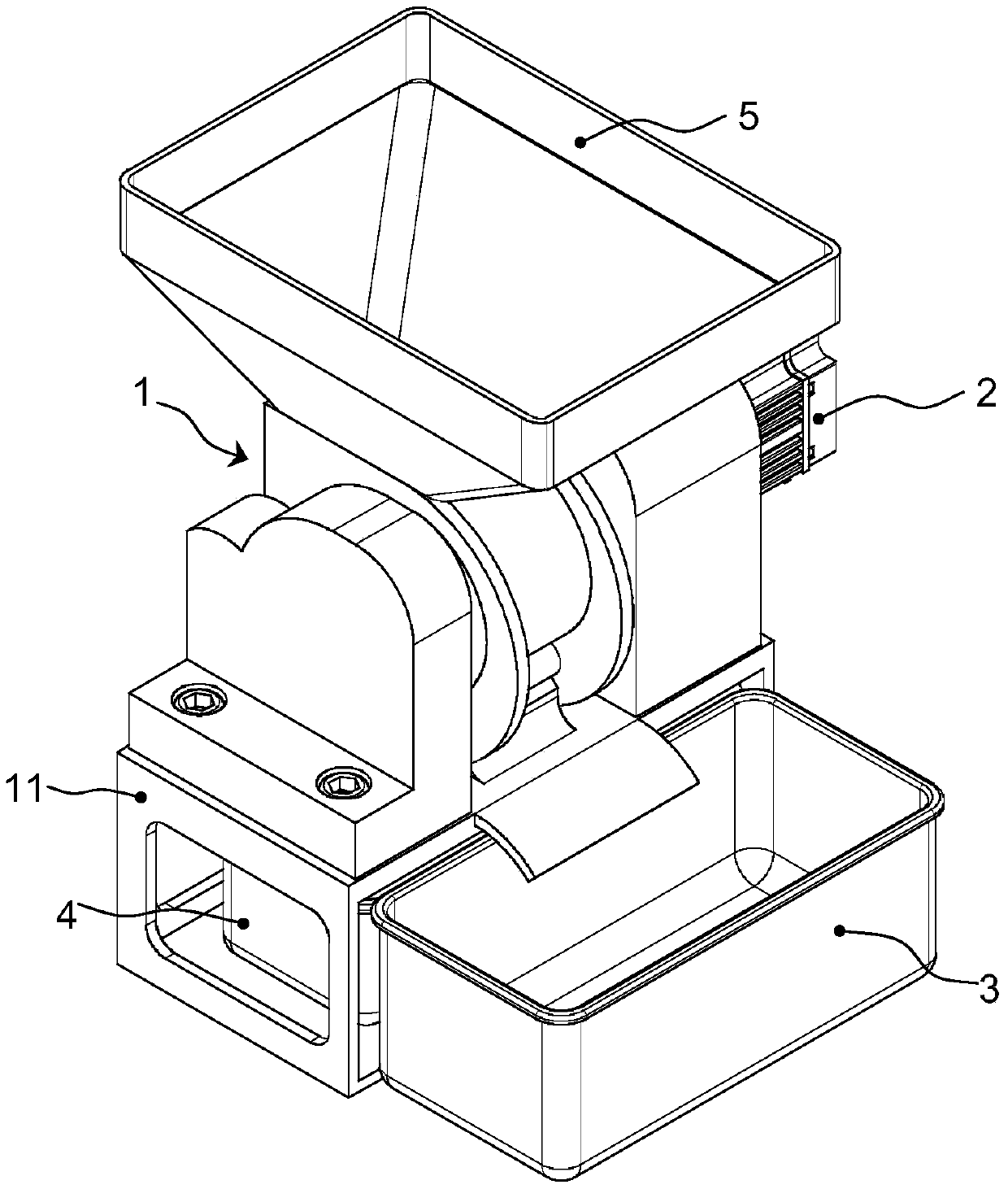

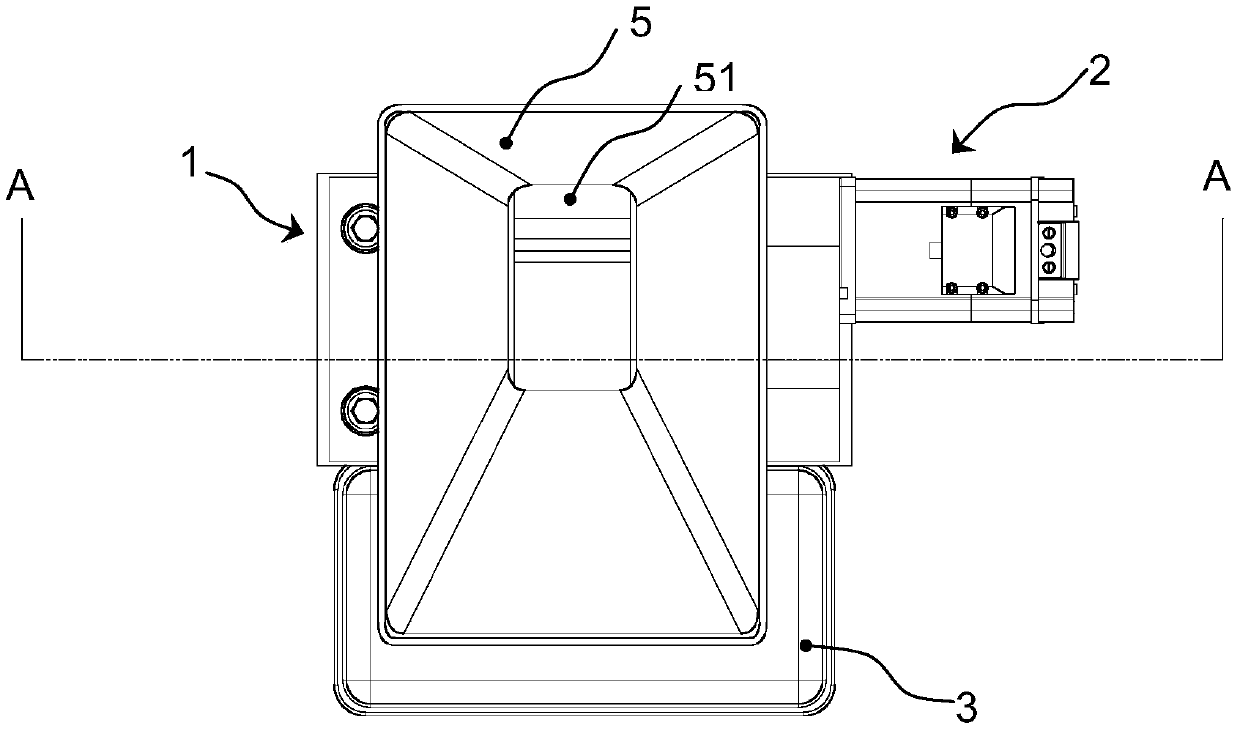

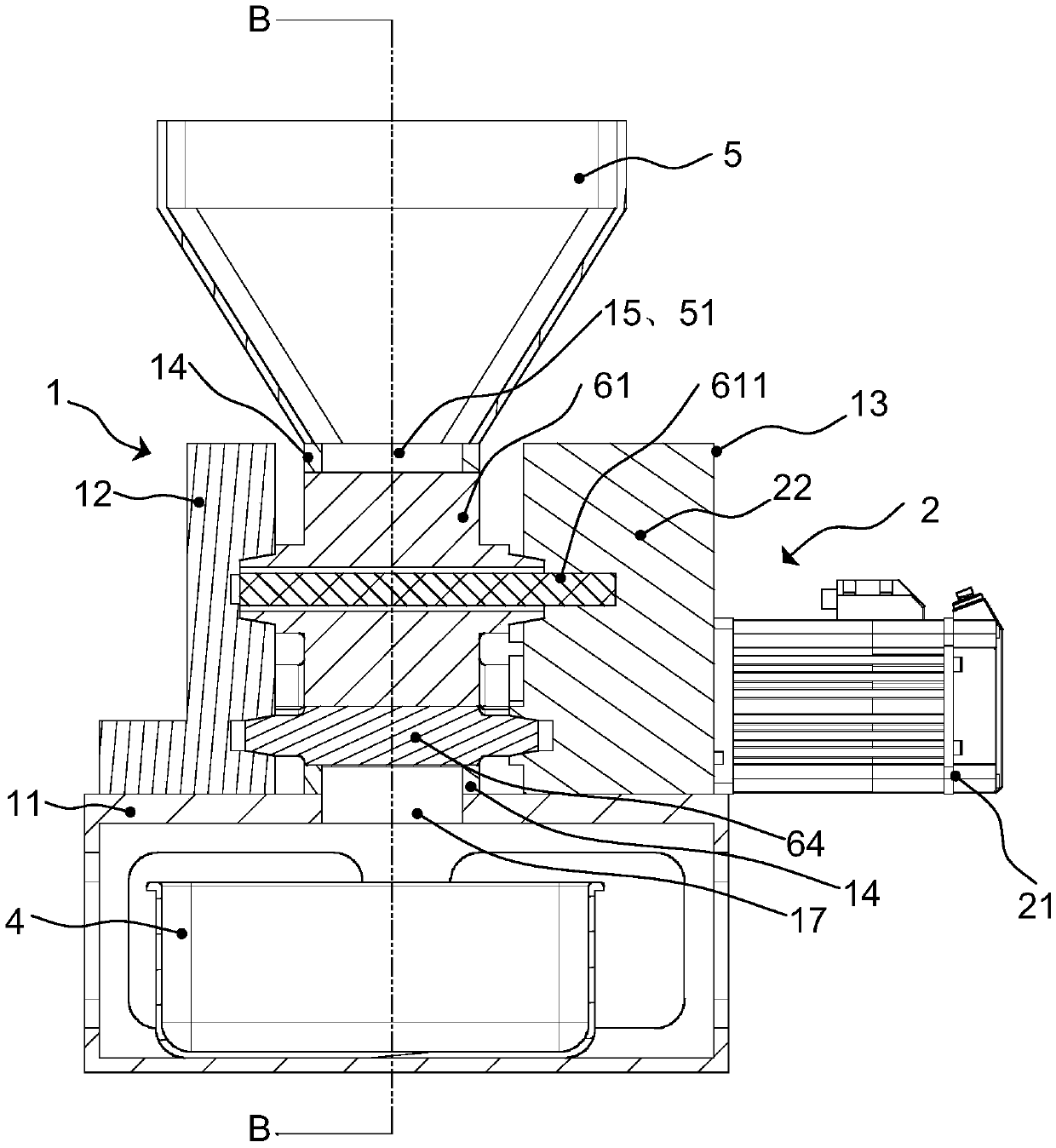

[0038] Such as figure 1 , figure 2 As shown, the embodiment of the present invention provides an oil press, including a frame 1, a power unit 2, a hopper 3, an oil box 4, a silo 5 and a temperature control device. The bottom of the frame 1 can be a hollow Underframe 11, frame 1 top is feed inlet 15 (seeing Figure 2 to Figure 4 ), the bottom can be the oil outlet 16, the side can be the slag outlet, and the inside of the frame 1 can be formed as a pressing chamber.

[0039] Such as figure 1 , figure 2 As shown, a power unit 2 is installed on one side of the frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com