Method for measuring deformation of large-scale tunnel

A measurement method and technology of deformation, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of poor measurement accuracy, low measurement accuracy, and large degree of interference, so as to achieve convenient data collection, good data integrity, The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

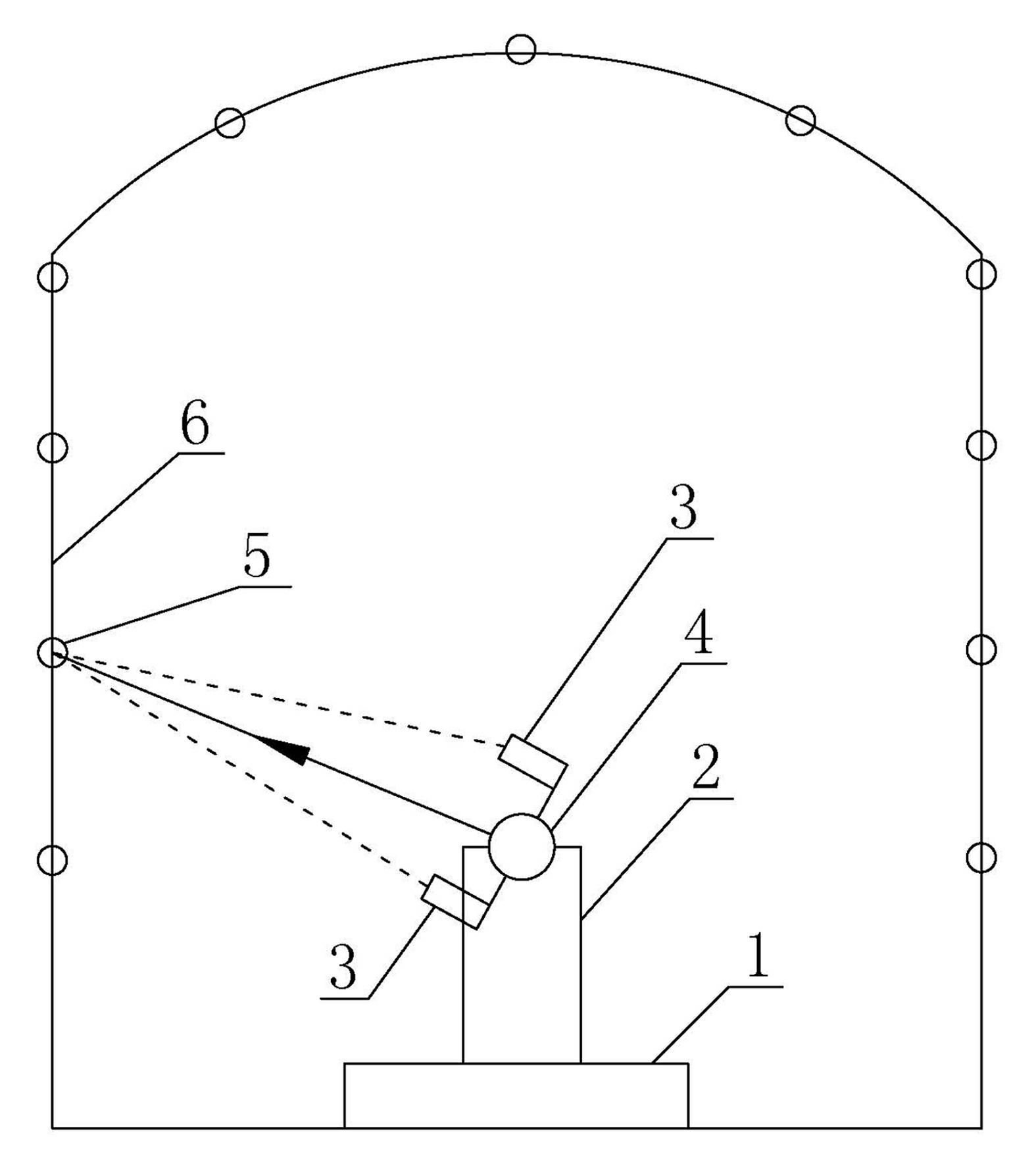

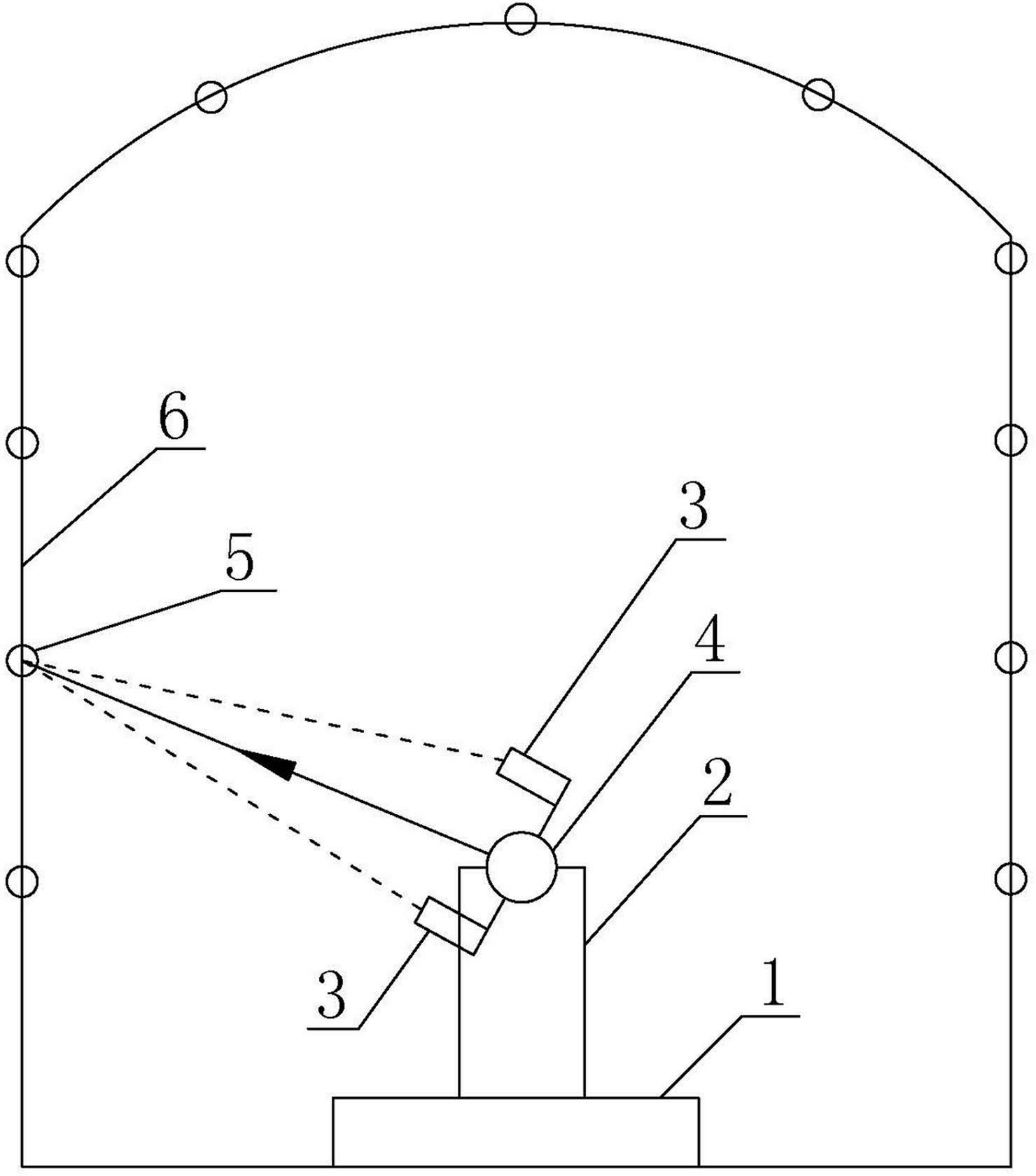

[0018] refer to figure 1 As shown, the large-scale tunnel deformation measurement method of the present embodiment includes the following steps:

[0019] Step 1. Install the image acquisition device:

[0020] A car 2 that can travel in the tunnel is arranged in the tunnel to be tested, and an image acquisition device assembled from a point laser 4, a camera 3, a lens and a lighting lamp is installed on the car 2, so that the car can travel in the tunnel , the camera 3 can collect images of the tunnel wall at any time for subsequent analysis. Wherein there are two cameras 3, thus forming a binocular camera.

[0021] In order to facilitate the travel of trolley 2, a motion controller is also installed on trolley 2 in this example, and track 1 is arranged in the tunnel. Among them: the motion controller can control the movement of the trolley in the tunnel; the structure of track 1 is similar to the subway rails in the subway tunnel, and it should be ensured that the track 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com