Method for determining flowing state of medium in pipeline for ultrasonic gas meter

A state judgment and medium flow technology, which is applied in the field of medium flow state judgment in the pipeline of ultrasonic gas meters, can solve the problems of slow response and increased power consumption of the whole gas meter, so as to prevent misoperation, ensure long-term stability, reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and embodiments.

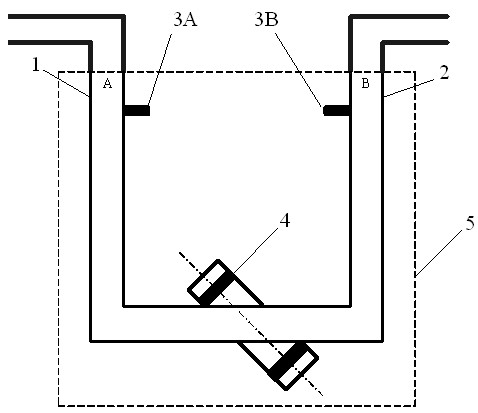

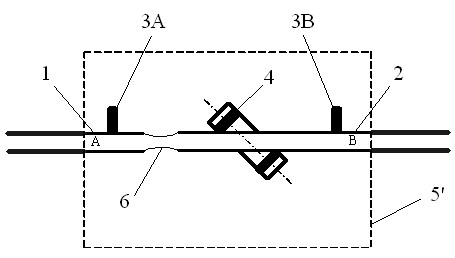

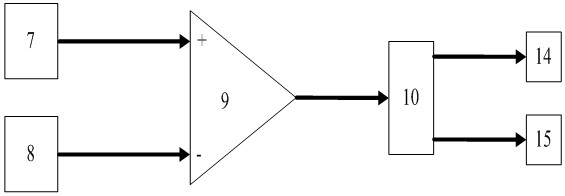

[0027] like figure 1 , figure 2 As shown, pressure sensors 3A and 3B are installed in the measuring pipe section of the ultrasonic gas meter near the inlet 1 and the outlet 2, respectively, to monitor the pressure difference between the inlet 1 and the outlet 2 of the gas meter in real time. According to the flow of the medium in the fluid mechanics It is a physical phenomenon that the pressure difference generated by the resistance element is proportional to the square of the medium flow rate, and the measured pressure difference and its changes can be used to quickly determine whether the medium in the pipeline is flowing or stagnant. When the pressure difference between the inlet 1 and the outlet 2 of the ultrasonic gas meter is greater than the preset value, the medium in the pipeline is considered to be in a flowing state; when the pressure differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com