Measuring method of trace impurities in high-purity tantalum

A technology for trace impurities and determination methods, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of high sensitivity, poor stability, and low determination lower limit, and achieve the effects of low detection cost, avoidance of errors, and less interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

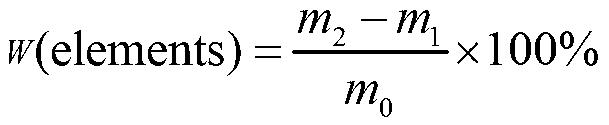

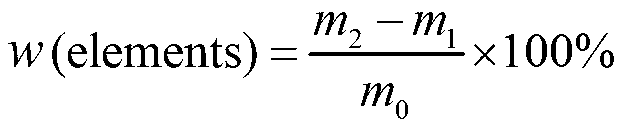

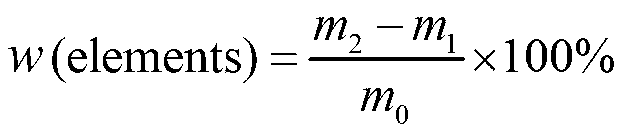

Image

Examples

Embodiment Construction

[0020] Weigh 0.3g of tantalum sample into a polytetrafluoroethylene beaker, add 3mL of hydrofluoric acid, and then add 0.5mL of nitric acid dropwise. Place the beaker in a flat electric furnace and heat it at low temperature until the sample is completely dissolved. After cooling, fill it with a 100mL volumetric flask and mix well.

[0021] Connect the three devices of ion chromatography, membrane desolvation device and ICP-MS, and adopt ion chromatography-membrane desolvation-ICP-MS online detection. The prepared sample solution is pumped into the cation exchange column (sulfonic acid type cation exchange column) of ion chromatography by the concentrated pump, the cation formed by impurity elements is adsorbed on the exchange column, and the TaF formed by matrix tantalum 7 2- or TaOF 5 2- The flow through the column is not applied to the column, and the exchange column is rinsed with 2vol% hydrofluoric acid to rinse the residual matrix on the column. Start the online work...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap