Automobile wheel speed sensor

A wheel speed sensor and magnetoresistive sensor technology, applied in the field of sensors, can solve the problem of high cost of automobile wheel speed sensors, achieve effective electromagnetic interference, improve stability, and stabilize signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

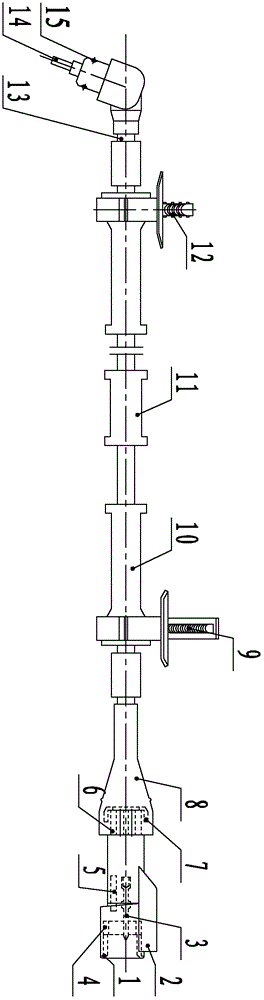

[0011] Such as figure 1 Shown, be the embodiment of the automobile wheel speed sensor of the present invention, comprise a plug, a high temperature wire 13, a magnet, a reluctance sensor chip 14 and an additional capacitance, described reluctance sensor chip, magnet and additional capacitance are connected in parallel And it is packaged inside the sealing assembly, the end of the magnetoresistive sensor chip is exposed to the sealing assembly, the two ends of the high-temperature wire are respectively connected to the pin 3 of the plug and the magnetoresistive sensor chip, and the middle part of the high-temperature wire is provided with a fixed structure to fix it with the car body. An annular groove is formed around the exposed end of the magnetoresistive sensor chip 14 on the outside of the sealing assembly and an O-ring 15 is mounted thereon. The cross section of the magnetoresistive sensor chip 14 is square, the magnetoresistive sensor chip is welded to the high temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com