Ultrahigh-voltage oil-SF6 sleeve test device

A technology of UHV oil and test equipment, applied in measuring equipment, testing dielectric strength, instruments, etc., can solve the problems of single test capacity, low test voltage level, vertical arrangement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Markings in the attached drawings:

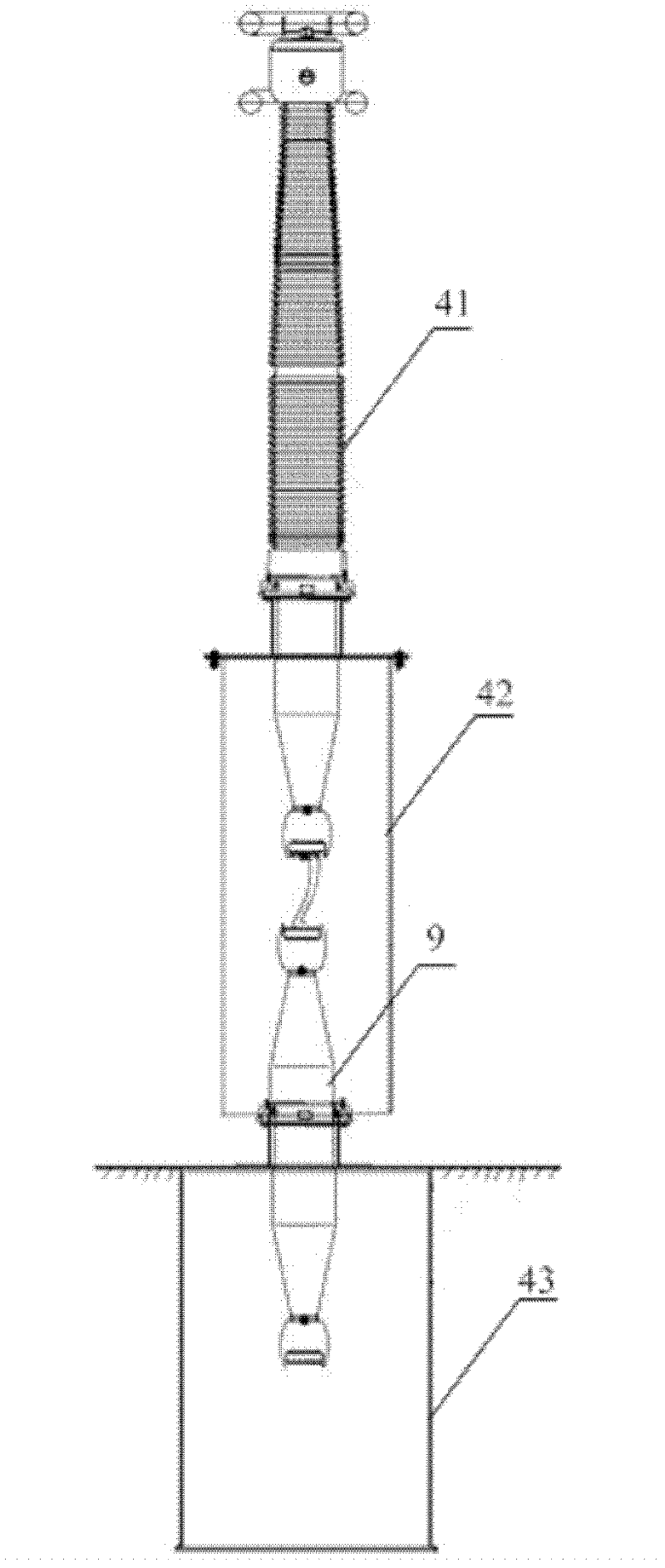

[0020] attached figure 1 Medium: 9-oil-SF 6 Casing, 41-pressurized casing, 42-transition cylinder, 43-conventional test oil tank;

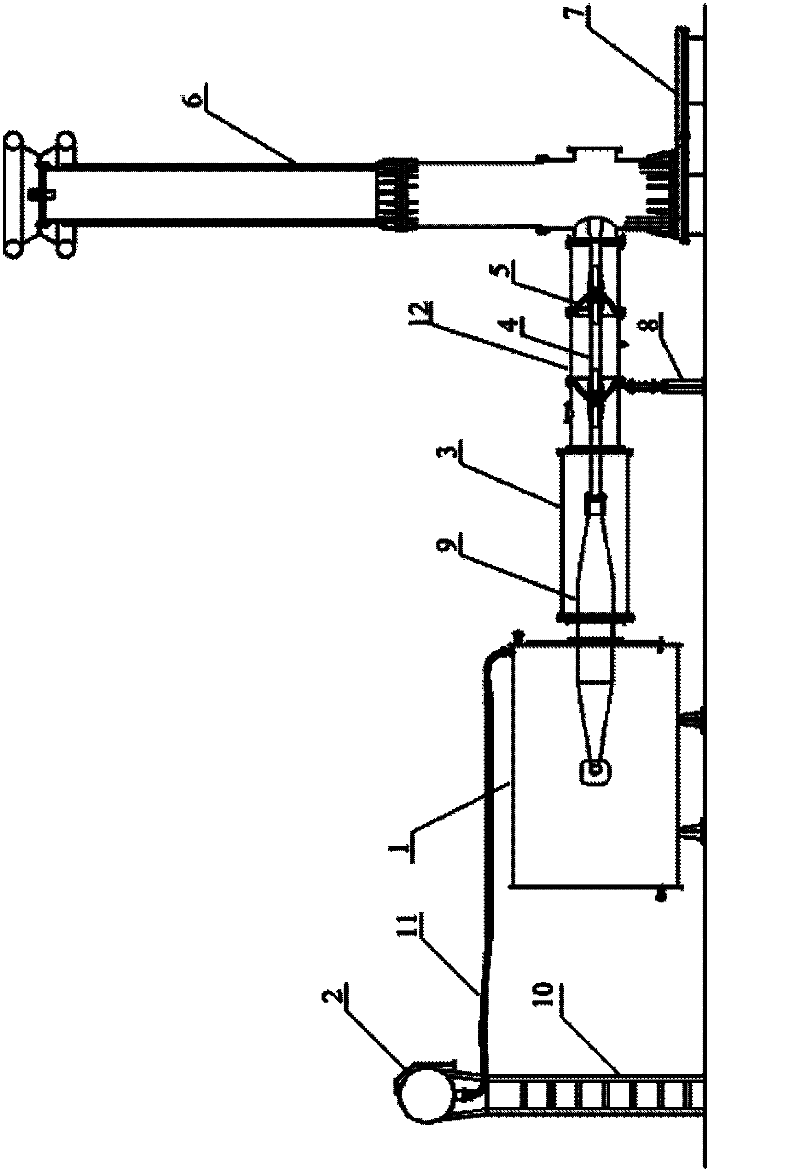

[0021] attached figure 2 Middle: 1-Test oil tank, 2-Oil pillow, 3-GIS bus barrel, 4-Conductive rod, 5-Pot insulator, 6-GIS bushing, 7-Support base, 8-GIS bus barrel support frame, 9- Oil-SF 6 Sleeve, 10-oil pillow support, 11-oil pipeline;

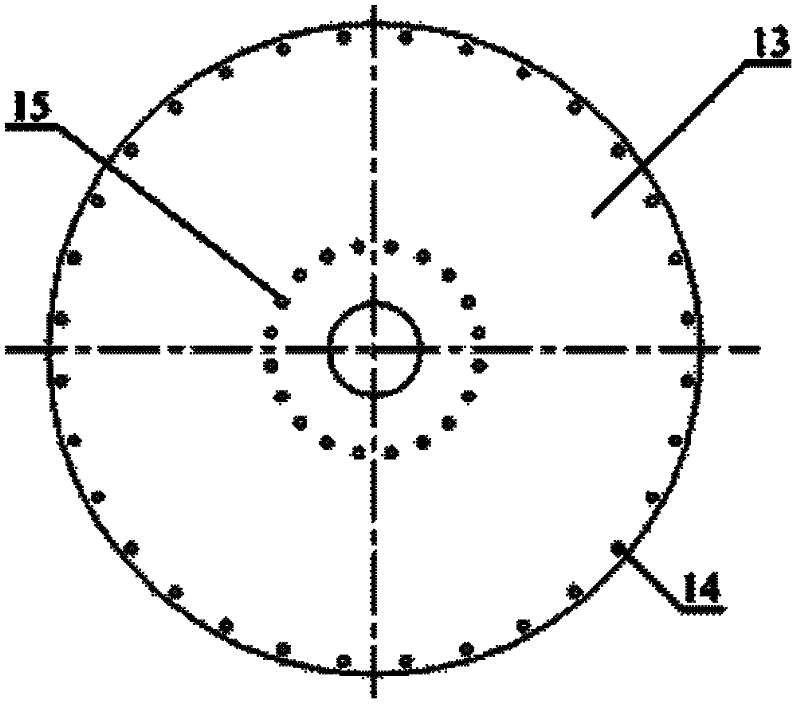

[0022] attached image 3 Middle: 13-transition plate, 14-outer ring screw hole, 15-inner ring screw hole;

[0023] attached Figure 4 ~ attached Image 6 Middle: 16-manhole, 17-oil sample plug, 18-vacuum valve, 19-top platinum thermal resistance, 20-top oil injection / drain valve, 21-temperature rise outlet terminal box, 22-manhole shielding cover Plate, 23-platinum thermal resistance at the bottom, 24-oil filling and discharging valve at the bottom, 25-drainage sleeve, 26-high current wire;

[0024] attached Figure 7 Middle: 12-GIS bus barrel, 27-GIS han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com