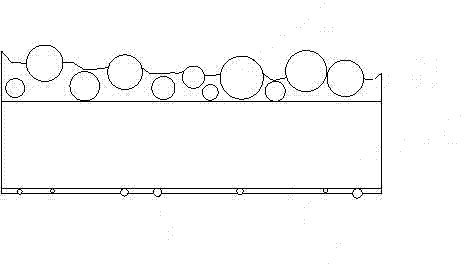

Optical diffusion film and method for preparing same

A technology of light diffusion film and diffusion layer, which is applied in the direction of chemical instruments and methods, optics, optical components, etc., can solve the problems of increased light loss and limited light-gathering ability of the diffusion film, achieve high optical uniformity and brightness, and increase brightness effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

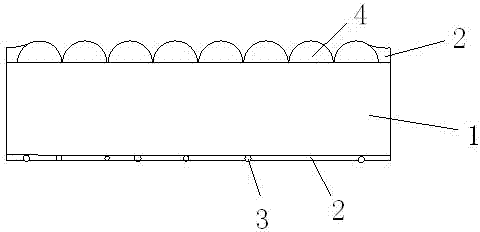

[0036] Embodiment 1, concrete preparation method is:

[0037] 1. Coating anti-superposition particles 3 on the back of the transparent base film 1: take a 250 ml Erlenmeyer flask, add 2 grams of anti-superposition particle silica, the average particle size is 5 microns, add 20 grams of polyacrylate, D 18 grams of ketone, 24 grams of toluene and 9 grams of butyl acetate, then add 36 grams of polyol resin, stir at a high speed, the stirring speed is 1000 rpm, and the stirring time is 15 minutes. The back of the base film 1 is placed in an oven, the drying temperature is 110° C., and the drying time is 1 minute. The thickness of the anti-lamination layer is 5 microns. At this time, the ratio of the area occupied by the anti-lamination particles 3 to the area of the anti-lamination layer is 1 / 500;

[0038] 2. Coating on a silicone rubber transfer plate with a concave structure to form diffusion particles 4: Take a 250 ml three-necked flask, add 20 grams of methacrylic resin, ...

Embodiment 2

[0040] Embodiment 2, concrete preparation method is:

[0041] 1. Coating anti-superposition particles 3 on the back of the transparent base film 1: take a 250 ml Erlenmeyer flask, add 3 grams of anti-superposition particle silica, the average particle size is 5 microns, add 20 grams of polyacrylate, D 18 grams of ketone, 24 grams of toluene and 9 grams of butyl acetate, then add 40 grams of polyol resin, stir at a high speed, the stirring speed is 1000 rpm, and the stirring time is 15 minutes. The back of the base film 1 is placed in an oven, the drying temperature is 110°C, and the drying time is 1 minute. The thickness of the anti-lamination layer is 5 microns. At this time, the ratio of the area occupied by the anti-lamination particles 3 to the area of the anti-lamination layer is 1 / 300;

[0042] 2. Coating on a silicone rubber transfer plate with a concave structure to form diffusion particles 4: Take a 250 ml three-necked flask, add 30 grams of methacrylic resin, 10...

Embodiment 3

[0044] Embodiment 3, concrete preparation method is:

[0045] 1. Coating anti-superposition particles 3 on the back of the transparent base film 1: take a 250 ml Erlenmeyer flask, add 1.2 grams of anti-superposition particle silica, the average particle size is 5 microns, add 20 grams of polyacrylate, D 18 grams of ketone, 24 grams of toluene and 9 grams of butyl acetate, then add 40 grams of polyol resin, stir at a high speed, the stirring speed is 1000 rpm, and the stirring time is 15 minutes. The back of the base film 1 is placed in an oven, the drying temperature is 110°C, and the drying time is 1 minute. The thickness of the anti-lamination layer is 5 microns. At this time, the ratio of the area occupied by the anti-lamination particles 3 to the area of the anti-lamination layer is 1 / 800;

[0046] 2. Coating on a silicone rubber transfer plate with a concave structure to form diffusion particles 4: Take a 250 ml three-necked flask, add 10 grams of methacrylic resin, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com