Parallax baffle plate, display panel and preparation method of parallax baffle plate

A parallax baffle and display technology, applied in optical components, optics, instruments, etc., can solve the problems of inability to convert to 2D display and no longer convertible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

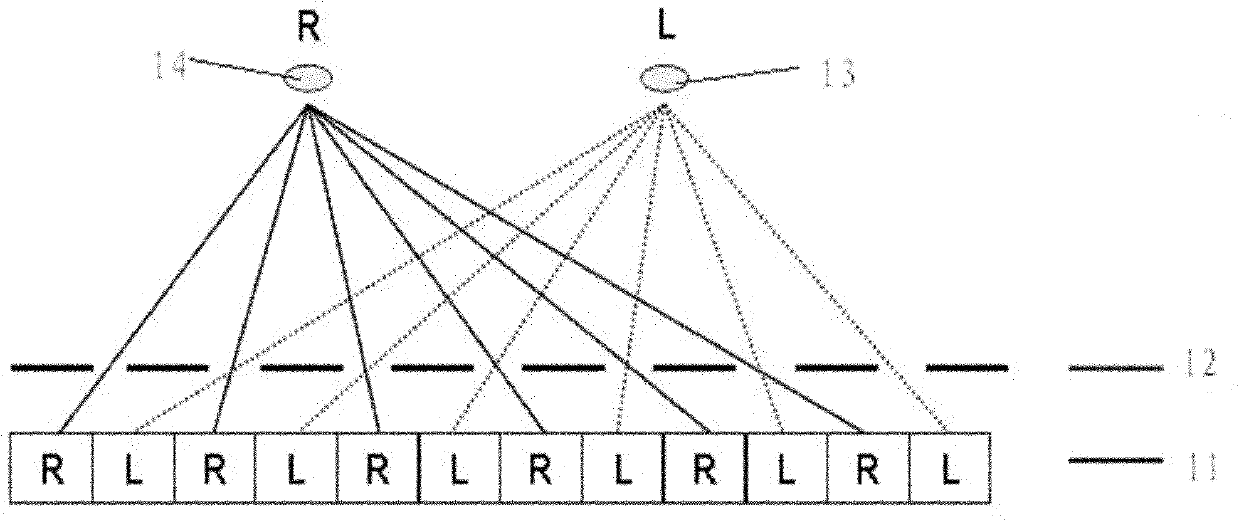

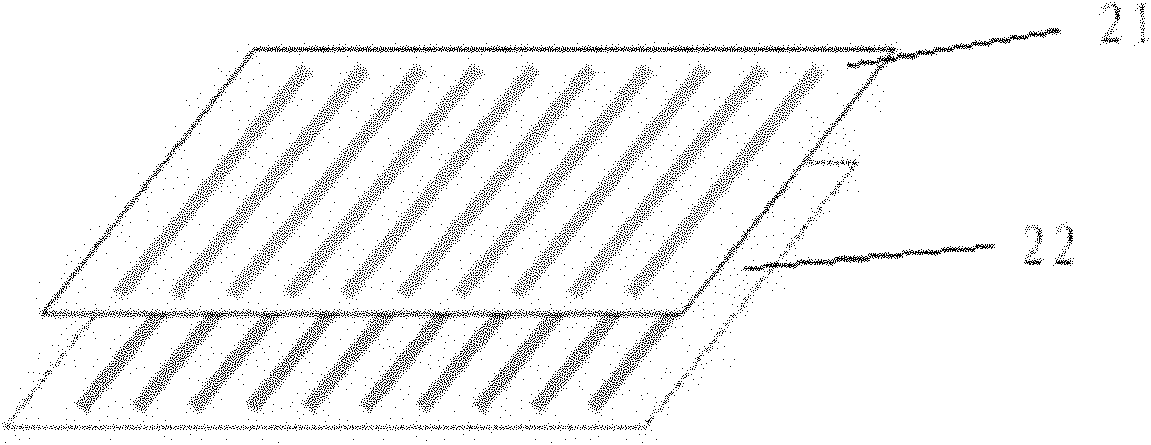

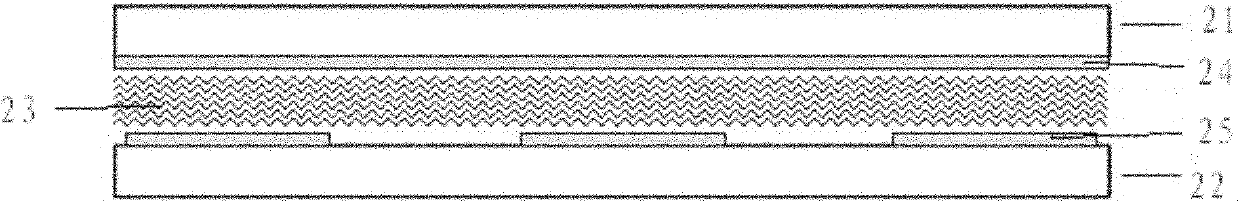

[0033] An embodiment of the present invention provides a parallax barrier, which specifically includes a transparent barrier, on which at least one group of patterns switching between a light-absorbing state and a light-transmitting state is provided, and each group of patterns is in a light-absorbing state , a slit grating for naked-eye three-dimensional display can be formed on the transparent baffle. Specific as figure 2 and image 3 As shown, the transparent baffle in the embodiment of the present invention includes two layers of overlapping transparent substrates 21 and 22, and a transparent liquid 23 filled between the two layers of transparent substrates 21 and 22; the above two layers of transparent substrates can be used The sealing glue is combined to ensure that the filled transparent liquid will not seep out, and the thickness of the box can be controlled by a spacer between the transparent substrates after the combination. In order to form a slit grating for na...

Embodiment 2

[0056] An embodiment of the present invention provides a display panel, such as Figure 8 and Figure 9 As shown, a display unit is included, and at least one parallax barrier is provided on the display surface of the display unit. For the specific structure of the parallax barrier, reference may be made to the above-mentioned embodiment 1, which will not be repeated here.

[0057] When the display surface of the display unit is provided with a parallax barrier, generally there is only one best observation point. In order to have multiple best viewing points, the embodiment of the present invention can use a parallax barrier with multiple sets of patterned electrodes, and by switching between these patterned electrodes, the display panel has multiple best viewing points . For example: when the parallax barrier realizes the light-absorbing state of the corresponding area of the first type of patterned electrode, it is the first type of slit grating, and correspondingly has ...

Embodiment 3

[0073] An embodiment of the present invention provides a method for preparing a parallax barrier, the method comprising:

[0074] Step 1, forming transparent electrodes on two transparent substrates, wherein the transparent electrodes on one transparent substrate include a set of patterned electrodes or at least two sets of patterned electrodes that can be energized separately;

[0075] Step 2: combine the two transparent substrates formed with transparent electrodes, and fill the space between the two combined transparent substrates with a transparent liquid. The transparent liquid in the region corresponding to the patterned electrode in the energized state becomes opaque, forming a light-absorbing state pattern with the same shape as the patterned electrode in the energized state.

[0076] In the embodiment of the present invention, the upper and lower layers of transparent substrates can be relatively formed into an empty cell (Cell) with the sealing glue, and the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com