Remote monitoring and fault diagnosis system for numerical control machine tool

A fault diagnosis system, a technology for CNC machine tools, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of insufficient diagnosis accuracy and real-time performance, high cost, and lack of fault solutions, and achieve seamless Connectivity, Fast and Accurate Diagnosis, Easy-to-Achieve Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

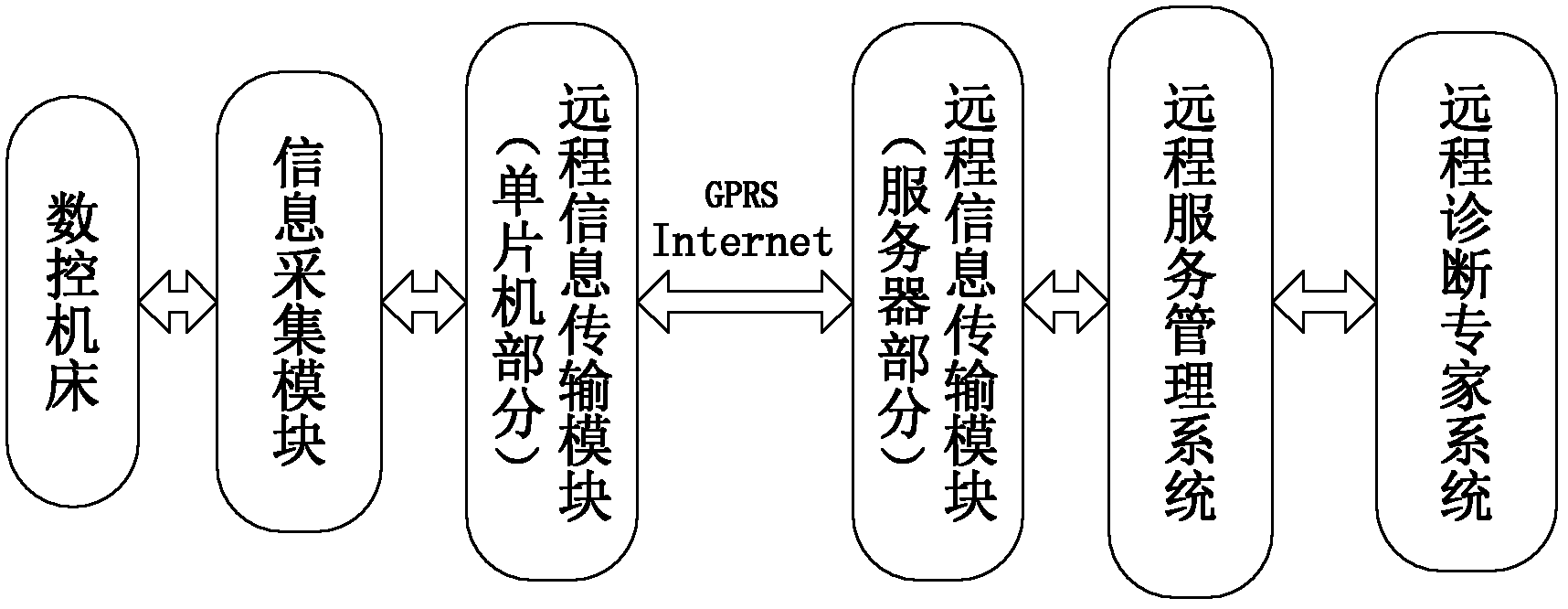

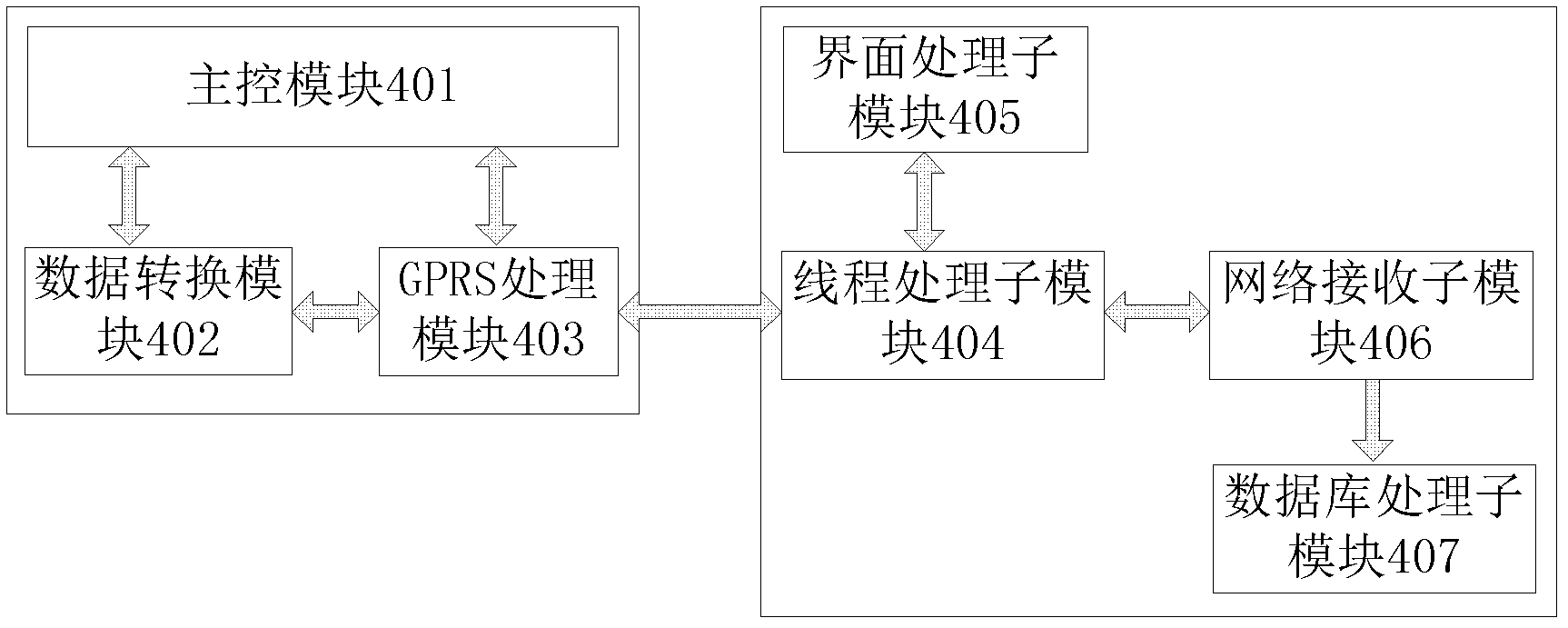

[0024] The remote monitoring and fault diagnosis system of the numerical control machine tool of the present invention is composed of three modules: an information collection module, an information transmission module, a remote service management and an expert system module. The information collection module collects the status information of the machine tool, and transmits the data to the remote service management and expert system module through the information transmission module and the Internet. machine tool.

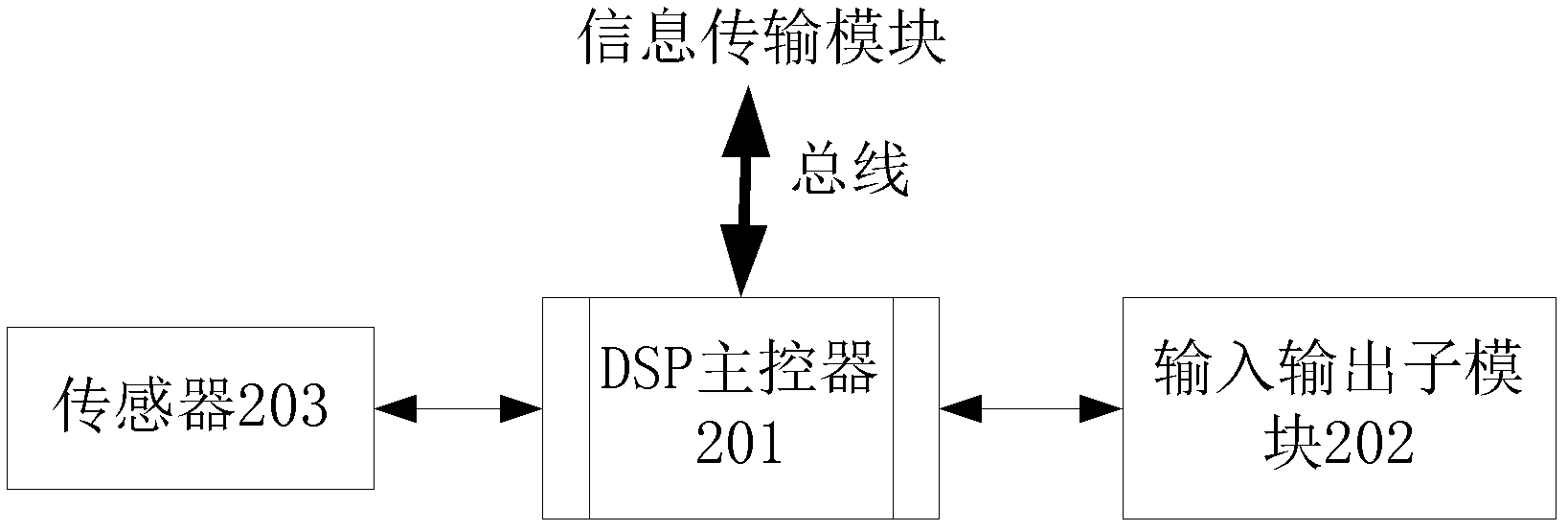

[0025] The airborne information collection module is composed of a DSP main controller 201 , an input and output sub-module 202 and a sensor 203 . DSP main controller 201 is the core of state monitoring and information processing of CNC machine tools. Its main functions are: real-time acquisition and data processing of signals inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com