Stamping die auxiliary designing method and system utilizing same

An auxiliary design and stamping die technology, applied in calculation, special data processing applications, instruments, etc., can solve the problem that the die design module cannot meet the rapid design, and achieve the effect of rapid design and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

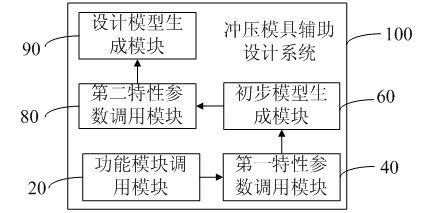

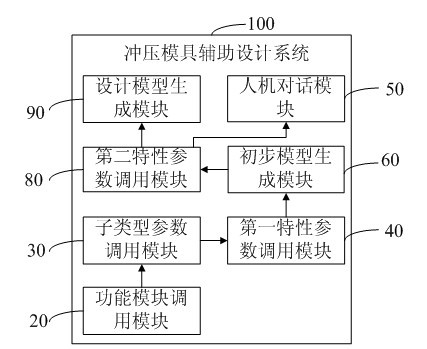

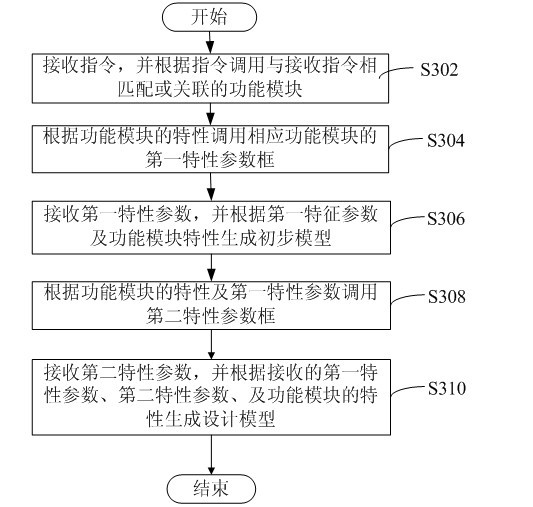

[0036] Such as figure 1 As shown, the stamping die auxiliary design system 100 of an embodiment of the present invention includes: a function module calling module 20, a first characteristic parameter calling module 40, a preliminary model generating module 60, a second characteristic parameter calling module 80, and a design model generating module 90.

[0037] Function module calling module 20: receiving a function module start instruction, and calling a matching function module according to the function module start instruction. Specifically, before design, the user or designer selects or clicks on the corresponding function module according to the type of product designed, the system receives the user's or designer's selection or click instruction, and calls the corresponding or matching module according to the user's selection instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com