Air forced cooling type direct current, low voltage and high-current switch

A high-current switching, DC low-voltage technology, applied in the field of switching, can solve problems such as deviation and total resistance exceeding 100mΩ, and achieve the effects of reducing heat generation, reducing heat generation, and precise time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

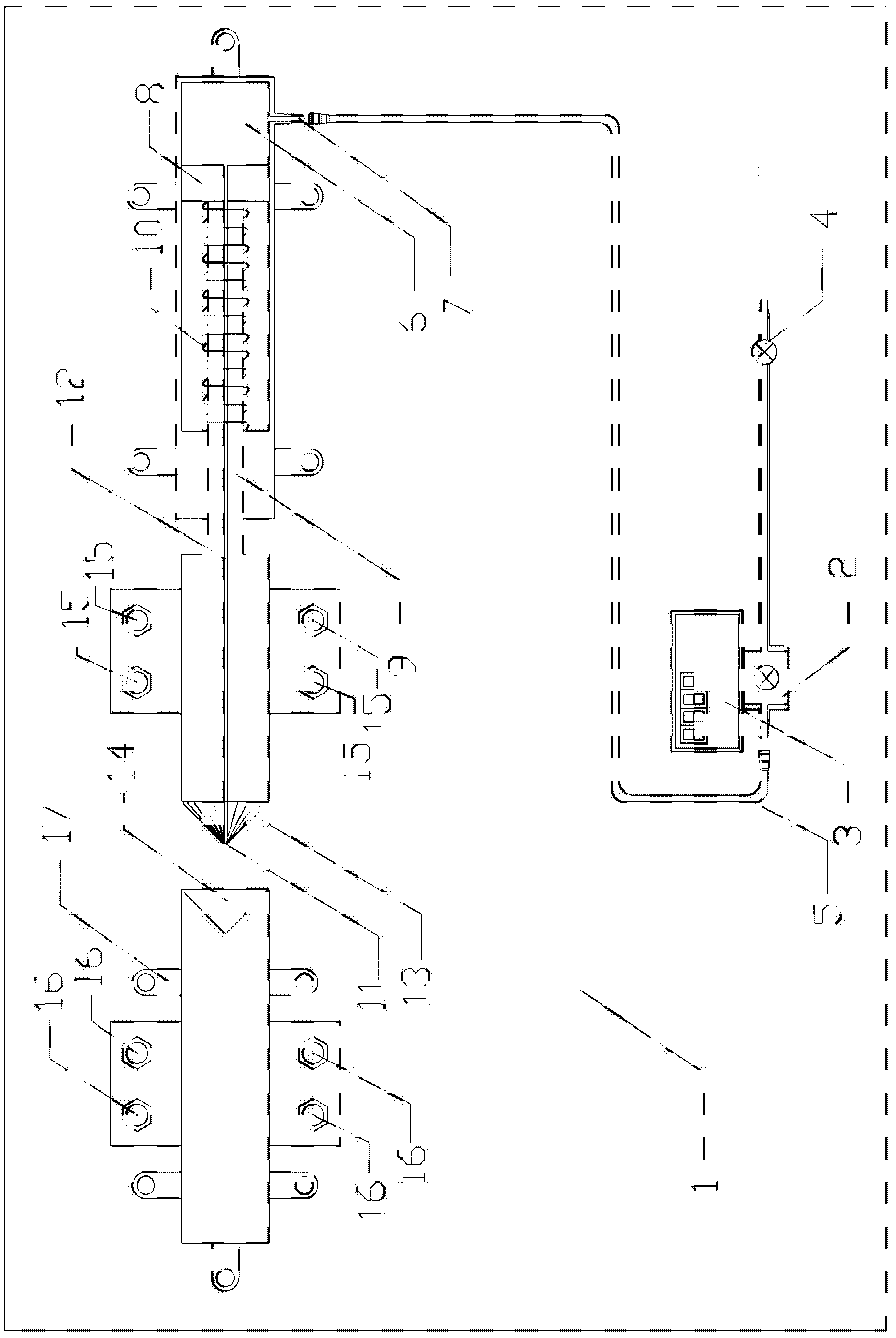

[0022] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0023] Such as figure 1 As shown, an air-cooled DC low-voltage high-current switch includes a base 1, a cylinder assembly, a piston assembly, an air supply assembly, a contact end assembly, a terminal assembly and a fixing nut 17; the cylinder assembly passes through the fixing nut 17 Fixed on the base 1, the piston assembly is inside the cylinder assembly and protrudes to the left, the contact end assembly is arranged on the top of the piston assembly, the air supply assembly is connected with the cylinder assembly, and the terminal assembly is connected with the contact end assembly;

[0024] During operation, at the moment when the switch is closed, the air supply component sprays compressed air to the contact end assembly through the cylinder assembly and the piston assembly in turn to cool the contact end assembly

[0025] The cylinder assembly includes a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com