Low current fuse

A technology for fuses and electrodes used in the manufacture of these fuses, land grid arrays and surface mount microcurrent fuses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

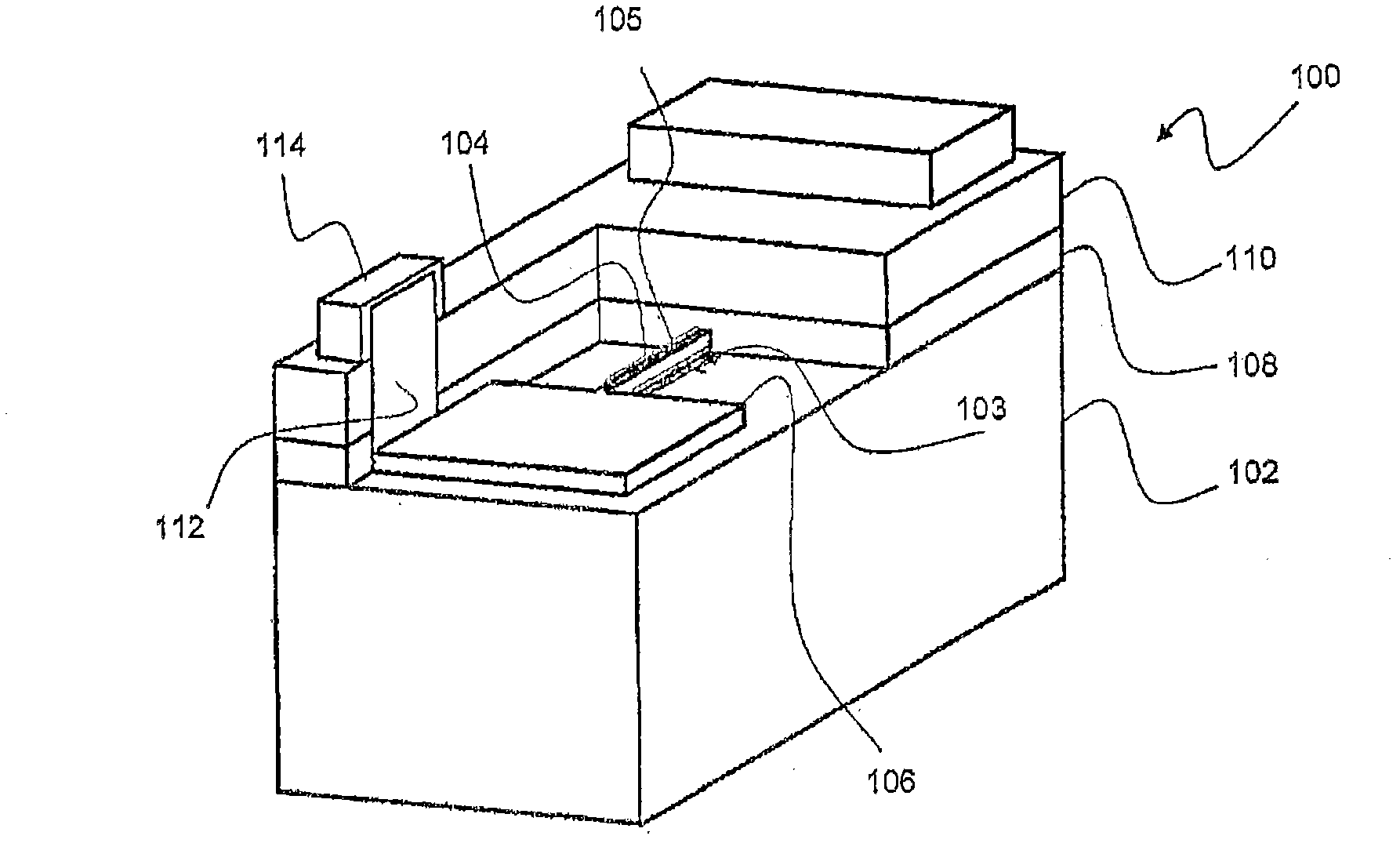

[0078] refer to figure 1 , the following preferred embodiments are intended to provide a low current fuse 100 rated to blow if exposed to a maximum current in excess of between 0.1 and 0.5 amps.

[0079] The required dimensions are precisely reproducible and the fuse needs to have a high electromigration resistance. Such precise low-current fuses can be obtained by depositing fuse element 104 comprising nickel or copper traces 3 to 20 μm (micrometers) wide, with a predetermined thickness in the range of 0.2 to 2 microns, and preferably There is an integral pad 106 .

[0080] A thin layer of tantalum 103 is preferably deposited first to obtain good adhesion and prevent interaction between the substrate 102 and the nickel fuse element 104 .

[0081] Glass is selected as the substrate 102 . It should be noted that various glasses, ceramics or glass-ceramics may be used.

[0082] The thin layer 103 of tantalum, which is typically several hundred Angstroms thick, can be deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com