Method for connecting external thread type posts of power battery

A connection method and external thread technology, applied in the field of battery assembly, can solve the problems of partial surface contact or even point contact, small effective contact area of nut, small effective contact area, etc. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0033] Such as figure 1 , 2 , 3 and 4: a method for connecting externally threaded poles of a power battery, comprising the following steps:

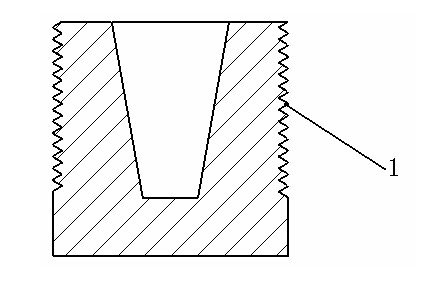

[0034] (1) Make two externally threaded poles 1 with tapered holes;

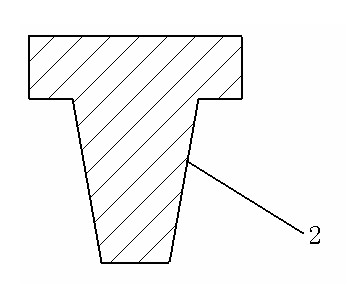

[0035] (2) Make two corresponding tapered joints 2 that match the tapered hole of the pole 1, and the tapered hole of the pole 1 is consistent with the taper of the tapered joint 2;

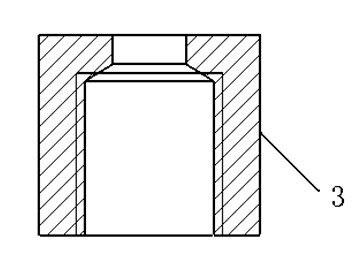

[0036] (3) Make two fastening sleeves 3 that penetrate up and down and have threads inside. The internal threads of the fastening sleeves 3 match the external threads of the pole 1;

[0037] (4) Use a connecting wire 4 to pass through the two fastening sleeves 3 at the same time, and connect the two ends of the connecting wire 4 to the cone bottoms of the two conical joints 2 respectively;

[0038] (5) Insert the two tapered joints 2 into the tapered holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com