Expand grid and manufacturing method thereof, lead storage battery polar plate using expand grid, and lead storage battery

A technology of drawing a mesh grille and a manufacturing method, which is applied in the directions of lead-acid battery electrodes, lead-acid batteries, battery electrodes, etc., can solve the problem of inadvertently wrinkling, affecting the stability of the pole plate, and unable to control the number and degree of formation, etc. problem, to achieve the effect of excellent discharge capacity and excellent cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] (Production of positive plate)

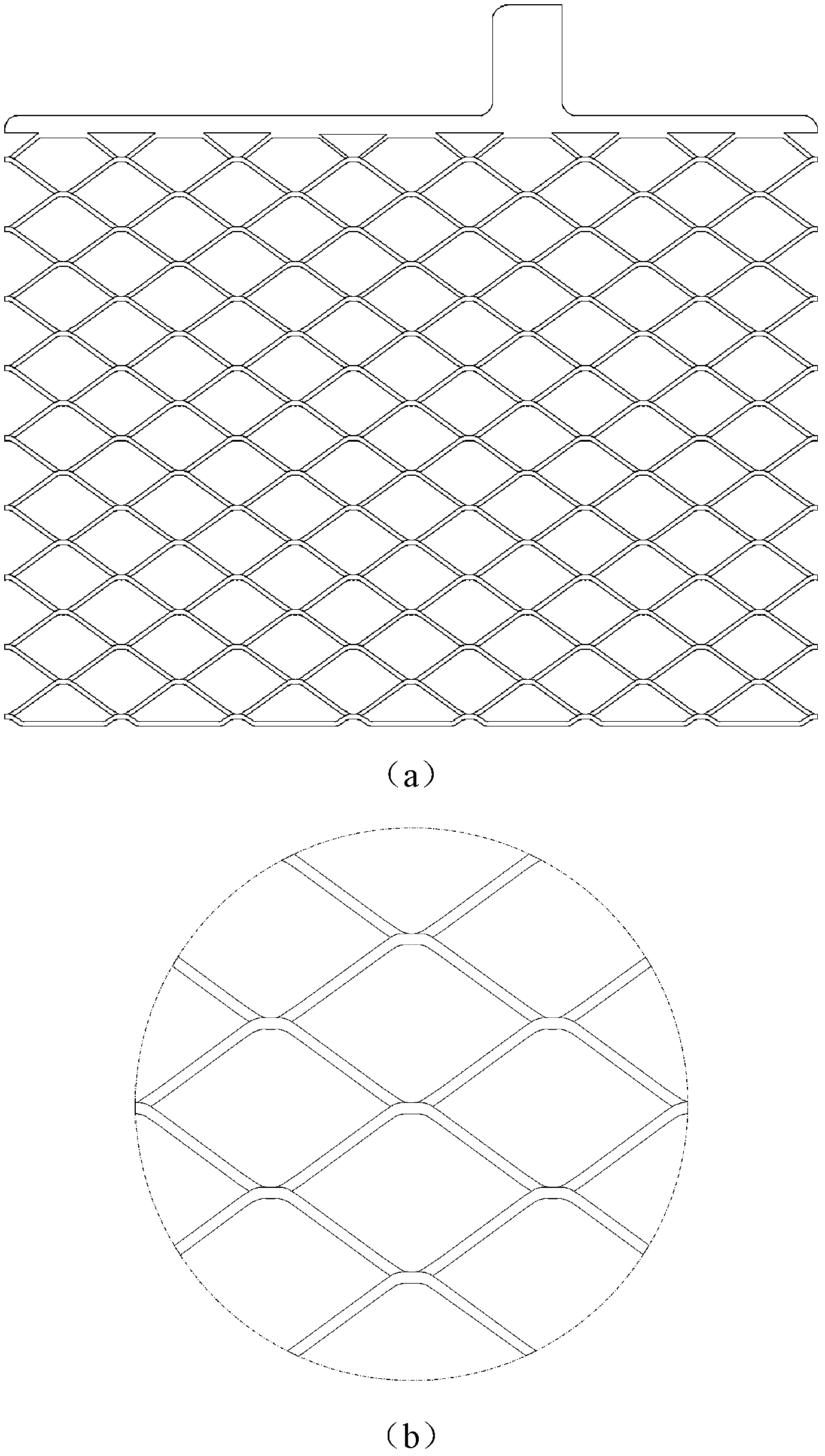

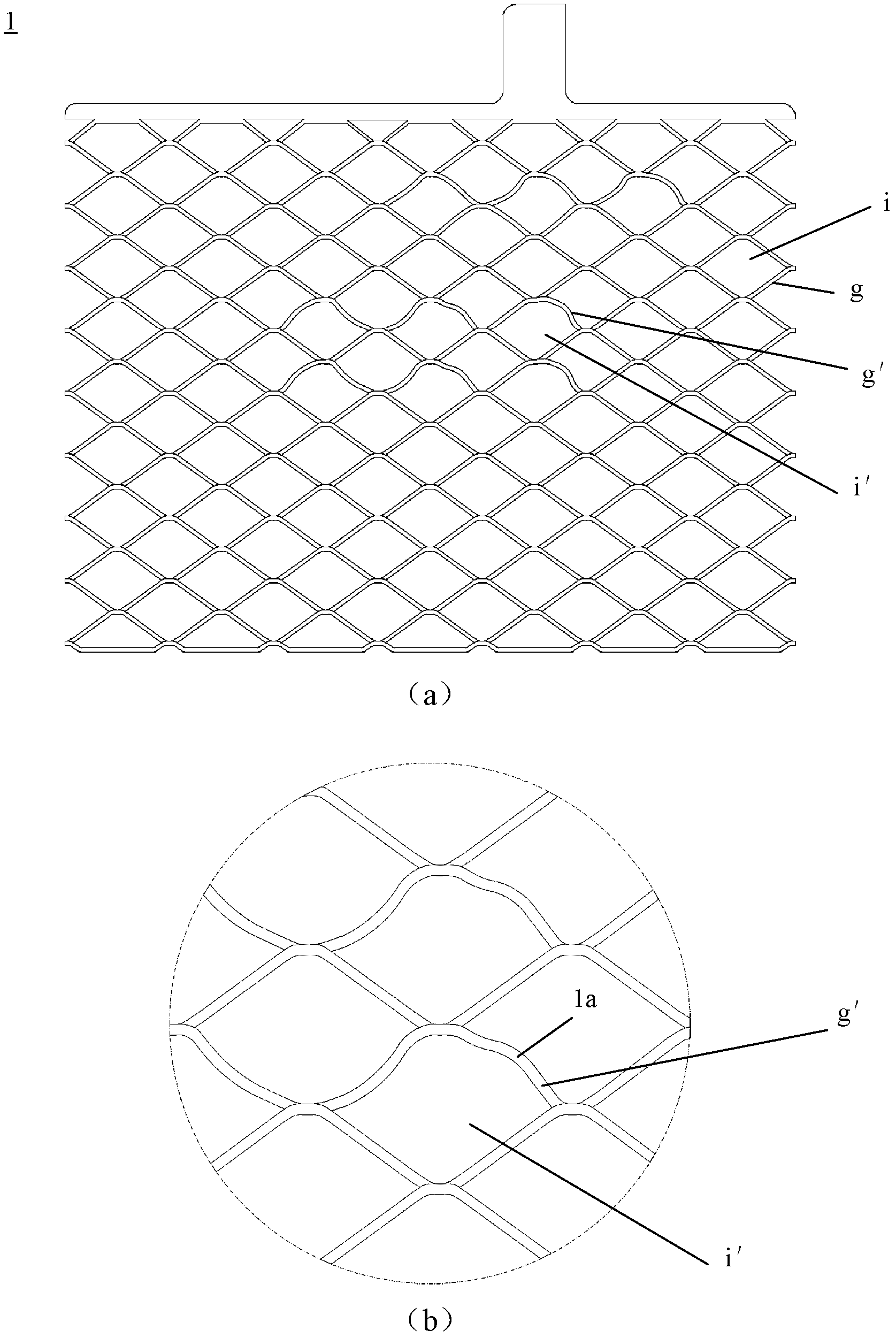

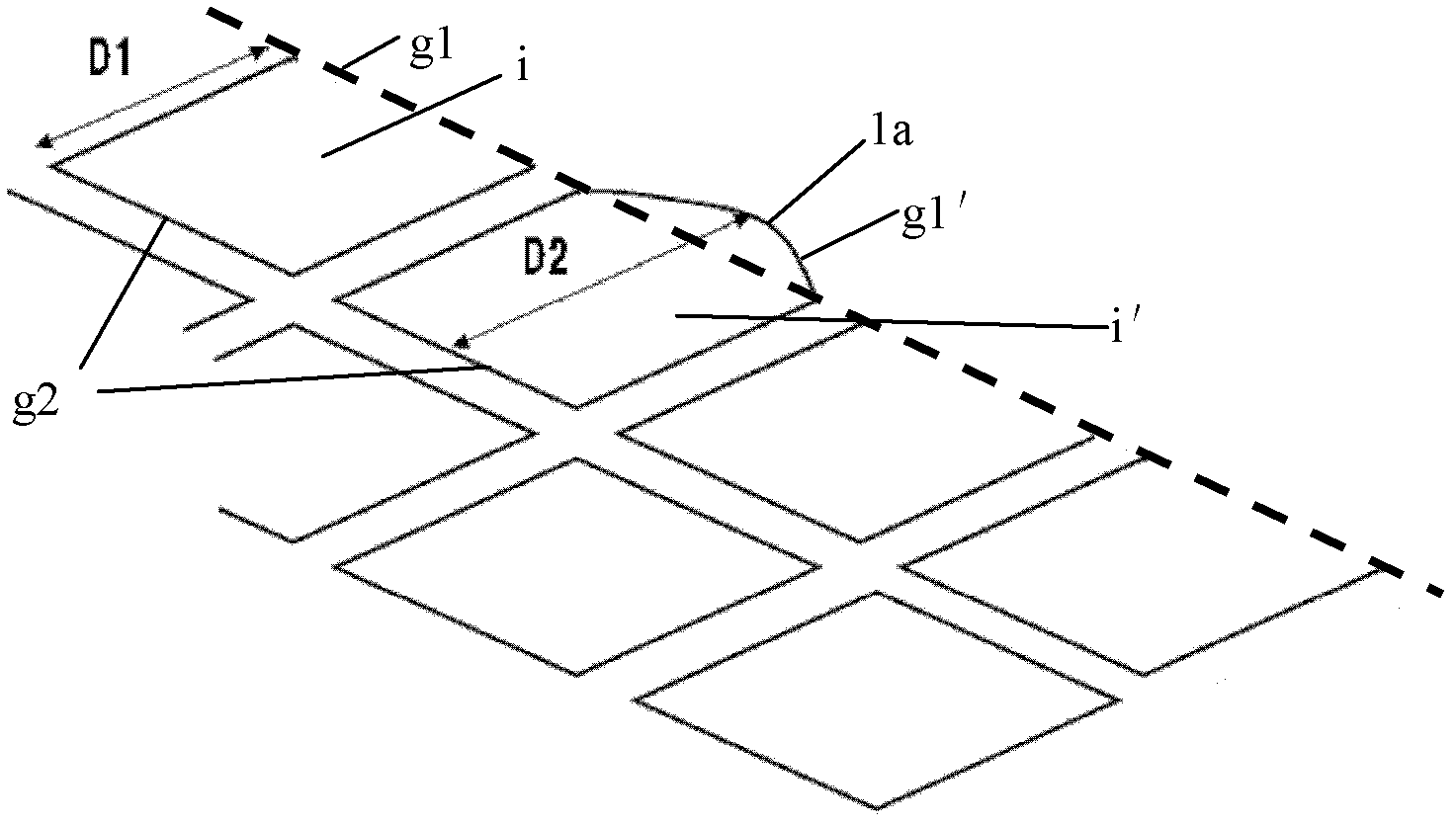

[0093] While feeding the raw material lead strip made of Pb-Ca-Sn ternary alloy flakes into the stamping die, external equipment controls the relative movement between the movable mold and the static mold, repeatedly punching the lead strip up and down, and then, using a shaping mold The obtained mesh sheet was shaped horizontally by the guide rollers to obtain a planar mesh.

[0094] Then, the raw material lead powder, water, and sulfuric acid were added and mixed at a weight ratio of 100:15:10 to obtain a positive electrode paste. Fill the positive lead paste on the reshaped mesh. Then, the mesh that is filled with lead paste is cut into prescribed shape and size, has obtained the expanded grid that has been filled with lead paste, forms positive plate of the present invention (longitudinal: 139mm, horizontal: 64mm, thick : 2.9mm).

[0095] During this process, the cutting depth and stroke number of the movable mold are adjusted by ...

Embodiment 2

[0107] In the production of the positive plate, the cutting depth and the number of strokes of the movable mold were adjusted by external equipment, so that the wrinkle occurrence rate measured on the expanded grid was 11%, and the wrinkle degree was 0.11. Except for this, a positive electrode plate was produced in the same manner as in Example 1, and a negative electrode plate and a lead acid battery were produced in the same manner as in Example 1.

Embodiment 3

[0109]In the production of the positive plate, the cutting depth and the number of strokes of the movable mold were adjusted by external equipment, so that the wrinkle occurrence rate measured on the expanded grid was 11%, and the wrinkle degree was 0.14. Except for this, a positive electrode plate was produced in the same manner as in Example 1, and a negative electrode plate and a lead acid battery were produced in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com