Preparation method of sulfur-fixation carrier material for positive electrode of lithium-sulfur battery

A lithium-sulfur battery and sulfur carrier technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve environmental hazards and other problems, and achieve good rate capacity, good discharge capacity, and significant rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the positive electrode sulfur-fixed carrier material of the lithium-sulfur battery comprises the following steps:

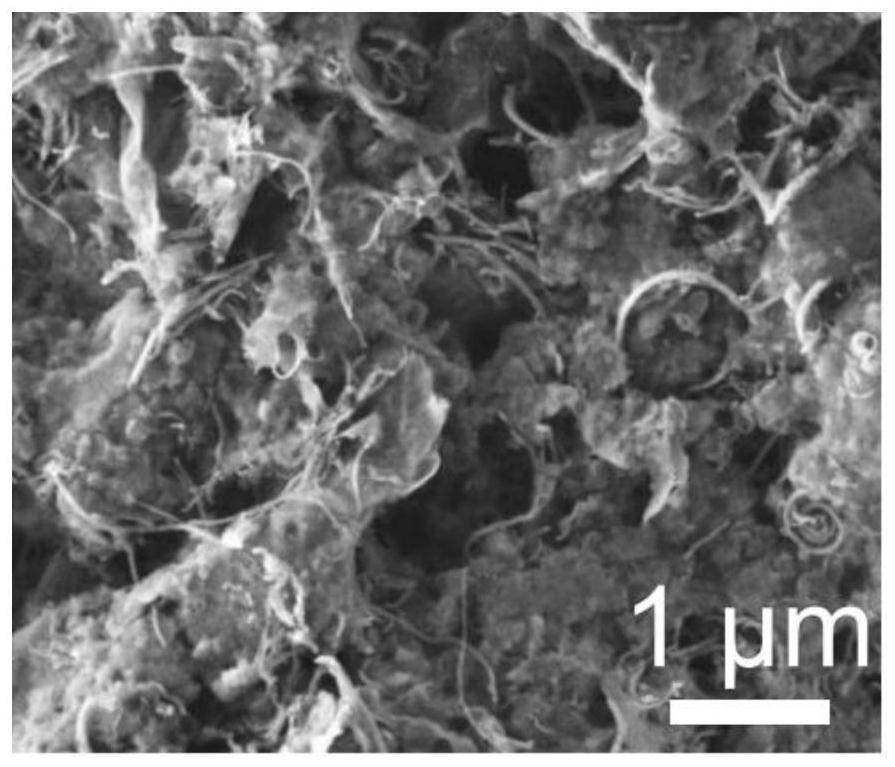

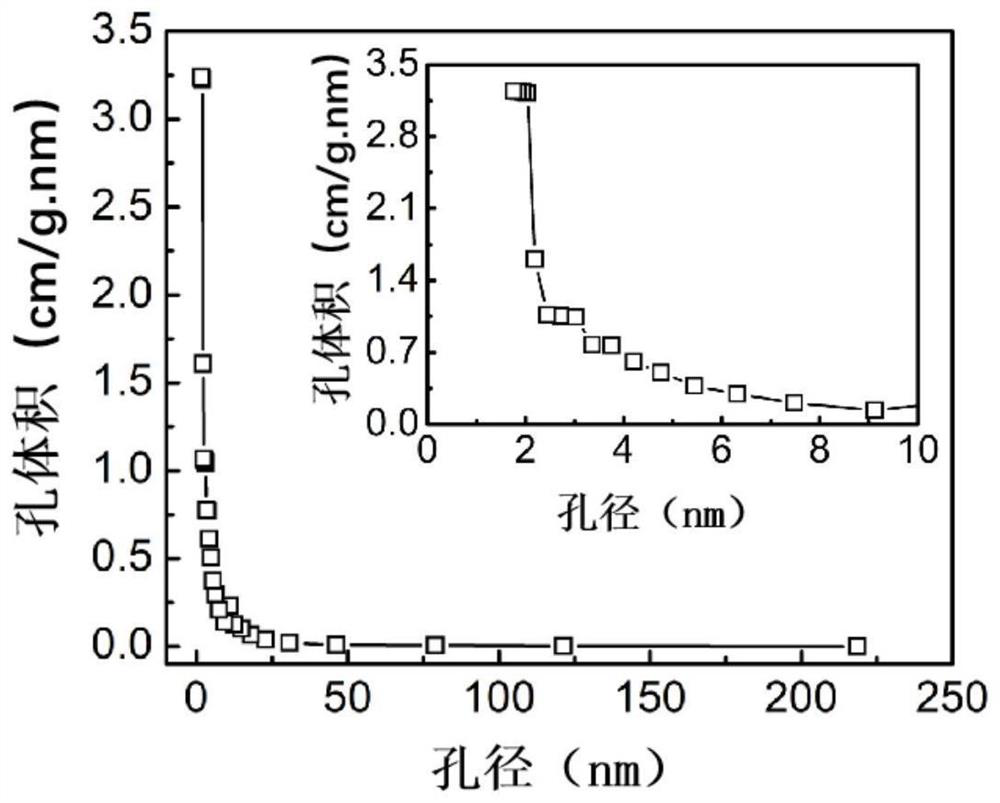

[0032] (1) Preparation of sponge-like porous g-C 3 N 4 : First, dissolve 1.5g of melamine in 90mL of deionized water, stir and dissolve at 90°C for 60 minutes to obtain a clear solution; After filtration, the precipitate was obtained; finally, the precipitate was heated up to 520°C at a rate of 2°C / min, and calcined in the air at 520°C for 4 hours to obtain a sponge-like porous g-C with a 3D network composed of porous nanosheets 3 N 4 ;

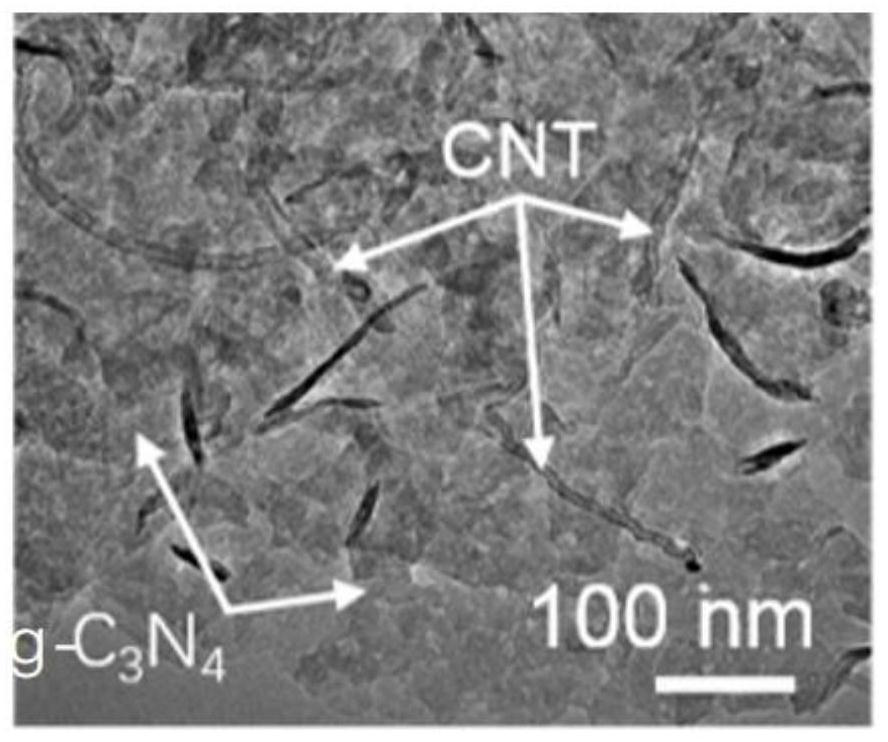

[0033] (2) Synthesis of in situ g-C 3 N 4 / CNT composite material: first, 0.2 g of the sponge-like porous g-C obtained in step (1) 3 N 4 Dissolve in 150mL deionized water, and make a suspension after ultrasonic treatment for 60min; then add 0.14gCNT into the prepared suspension, stir for 4h and dry at 60°C to obtain g-C 3 N 4 / CNT powder;

[0034] (3) g-C 3 N 4 / CNT composite material...

Embodiment 2

[0039] The preparation method of the positive electrode sulfur-fixed carrier material of the lithium-sulfur battery comprises the following steps:

[0040] (1) Preparation of sponge-like porous g-C 3 N 4 : Firstly, 1.0g melamine was dissolved in 60mL deionized water and stirred at 85°C for 30min to obtain a clear solution; After filtration, the precipitate was obtained; finally, the precipitate was heated up to 520°C at a rate of 3°C / min, and calcined in the air at 520°C for 3 hours to obtain a sponge-like porous g-C with a 3D network composed of porous nanosheets. 3 N 4 ;

[0041] (2) Synthesis of in situ g-C 3 N 4 / CNT composite material: first, 0.2 g of the sponge-like porous g-C obtained in step (1) 3 N 4 Dissolve in 150mL deionized water, and make a suspension after ultrasonic treatment for 60min; then add 0.14g of CNT to the prepared suspension, stir for 6h and dry at 60°C to obtain g-C 3 N 4 / CNT powder;

[0042] (3) g-C 3 N 4 / CNT composite material doped w...

Embodiment 3

[0044] The preparation method of the positive electrode sulfur-fixed carrier material of the lithium-sulfur battery comprises the following steps:

[0045] (1) Preparation of sponge-like porous g-C 3 N 4 : Firstly, dissolve 1.5g melamine in 100mL deionized water, stir and dissolve at 85°C for 30min to obtain a clear solution; then place the obtained clear solution in a 150mL polytetrafluoroethylene stainless steel autoclave, keep it warm at 195°C for 24h, and cool After filtration, the precipitate was obtained; finally, the precipitate was heated up to 520°C at a rate of 4°C / min, and calcined in the air at 520°C for 3 hours to obtain a sponge-like porous g-C with a 3D network composed of porous nanosheets. 3 N 4 ;

[0046] (2) Synthesis of in situ g-C 3 N 4 / CNT composite material: first, 0.2 g of the sponge-like porous g-C obtained in step (1) 3 N 4 Dissolved in 200mL of deionized water, ultrasonic treatment for 60min to make a suspension; then add 0.14g of CNT to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com