Positive plate and secondary battery

A cathode sheet and cathode film technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of soaring heat production, thermal runaway, combustion, etc., to achieve good discharge capacity, ensure stability, and improve safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

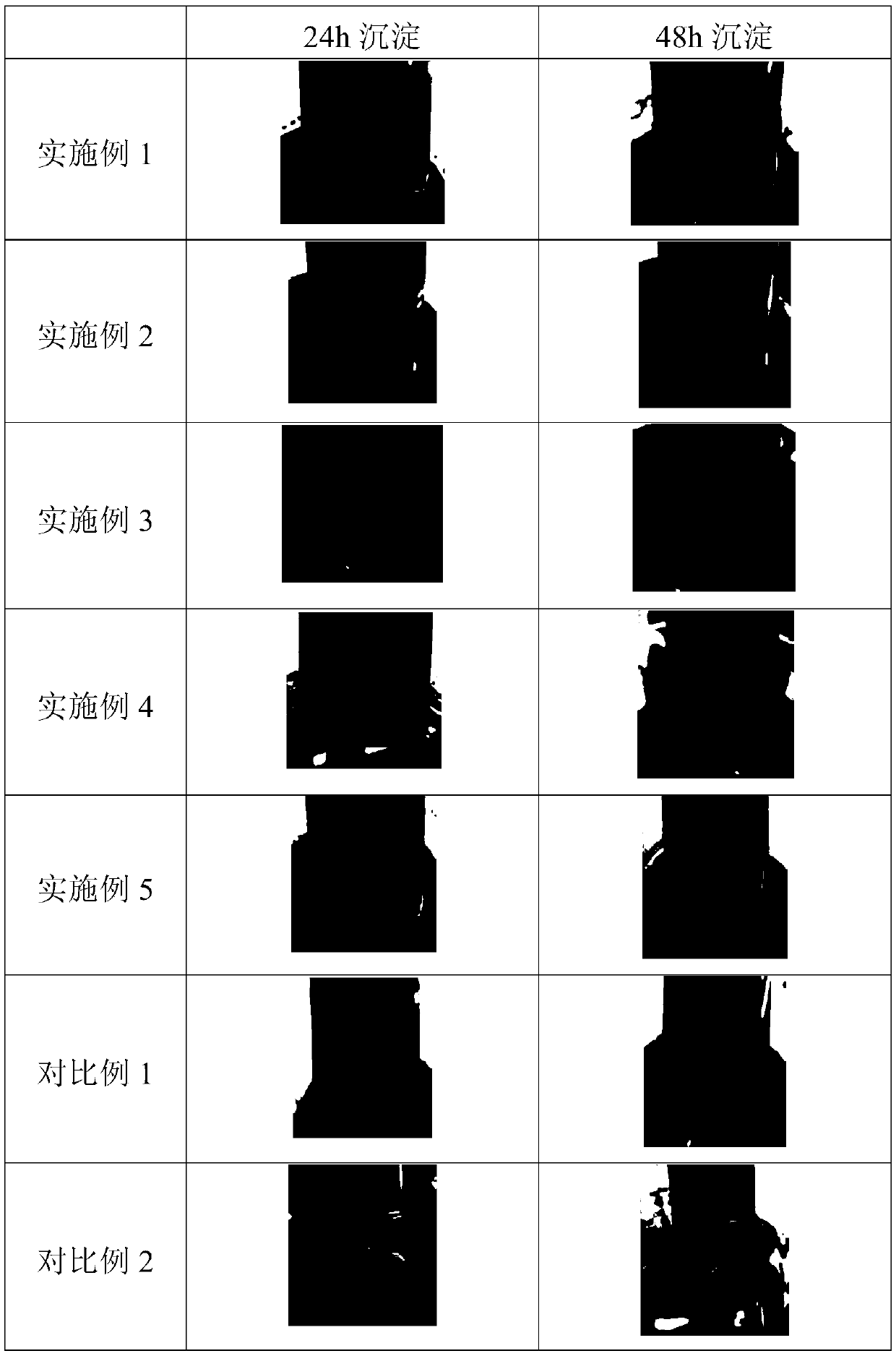

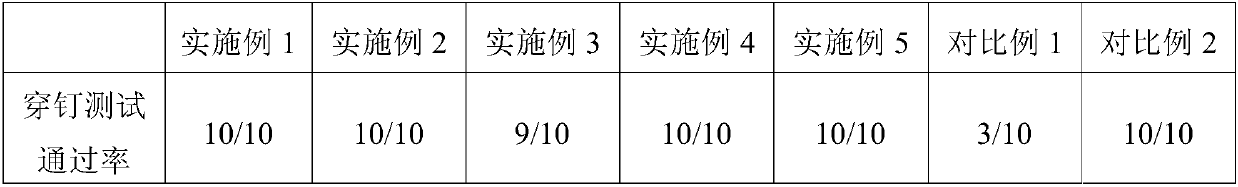

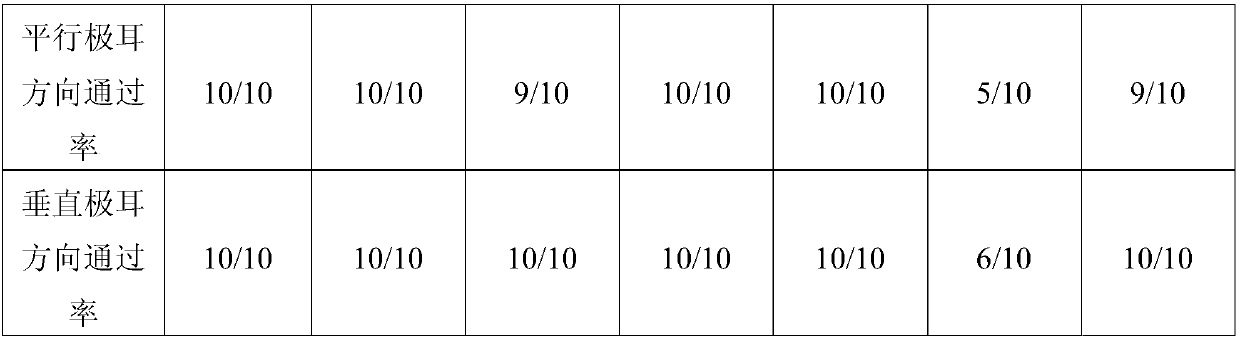

Examples

Embodiment 1

[0048] (1) Preparation of the second binder

[0049] In parts by weight, take 100 parts of E44 epoxy resin, 8 parts of curing agent dicyandiamide, 1 part of accelerator chlorourea, and 1 part of toughening agent dioctyl phthalate, stir on a planetary mixer to obtain a uniform mixture the second binder.

[0050] (2) Preparation of cathode slurry

[0051] At room temperature, mix the positive electrode active material LCO, the conductive agent SP, the first binder PVDF (model is HSV900), and the second binder in a weight ratio of 95:2:2:1, and add the solvent N-methylpyrrolidone (NMP), through high-speed stirring to obtain a homogeneously mixed positive electrode slurry.

[0052] (3) Preparation of positive electrode sheet

[0053] The positive electrode slurry is evenly coated on both sides of the positive electrode current collector aluminum Al foil with a thickness of 12 μm by using a coating machine. After drying at room temperature, it is transferred to an oven at 130 ° ...

Embodiment 2

[0059] The preparation process of lithium ion secondary battery is identical with embodiment 1, difference is:

[0060] (1) Preparation of the second binder

[0061] In terms of parts by weight, take 100 parts of E51 epoxy resin, 15 parts of curing agent adipic acid dihydrazide, and 1 part of toughening agent dioctyl phthalate, and stir on a planetary mixer to obtain a uniformly mixed second viscous Binder.

[0062] (3) Preparation of positive electrode sheet

[0063]Use a coating machine to evenly coat the positive electrode slurry on both sides of the aluminum foil of the positive electrode current collector with a thickness of 12 μm, dry it at room temperature, transfer it to an oven at 120°C to dry for 5 minutes, and then pass through a roller press machine for compaction, stripping, and cutting The positive electrode sheet is obtained after the sheet. The fan frequency of the coating machine is 35Hz-50Hz, and the belt speed is 5m / min.

Embodiment 3

[0065] The preparation process of lithium ion secondary battery is identical with embodiment 1, difference is:

[0066] (1) Preparation of the second binder

[0067] In parts by weight, take 100 parts of Ex48 epoxy resin, 5 parts of curing agent boron trifluoride monoethylamine complex, and 1 part of toughening agent dioctyl phthalate, stir on a planetary mixer to obtain a uniform mixture the second binder.

[0068] (3) Preparation of positive electrode sheet

[0069] Use a coating machine to evenly coat the positive electrode slurry on both sides of the aluminum foil of the positive electrode current collector with a thickness of 12 μm, dry it at room temperature, transfer it to an oven at 120°C to dry for 5 minutes, and then pass through a roller press machine for compaction, stripping, and cutting The positive electrode sheet is obtained after the sheet. The fan frequency of the coating machine is 35Hz-50Hz, and the belt speed is 5m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com