Preparation method of hydrogen storage alloy composite material

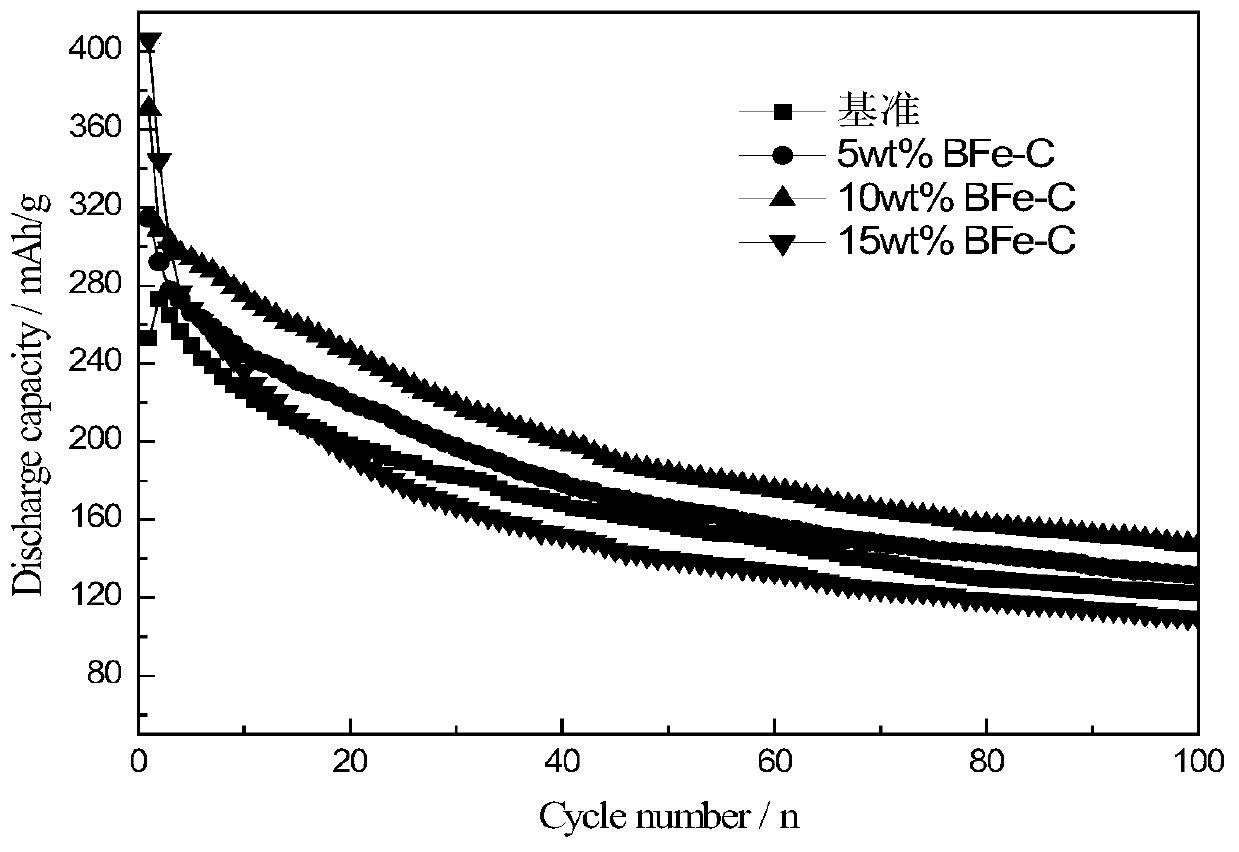

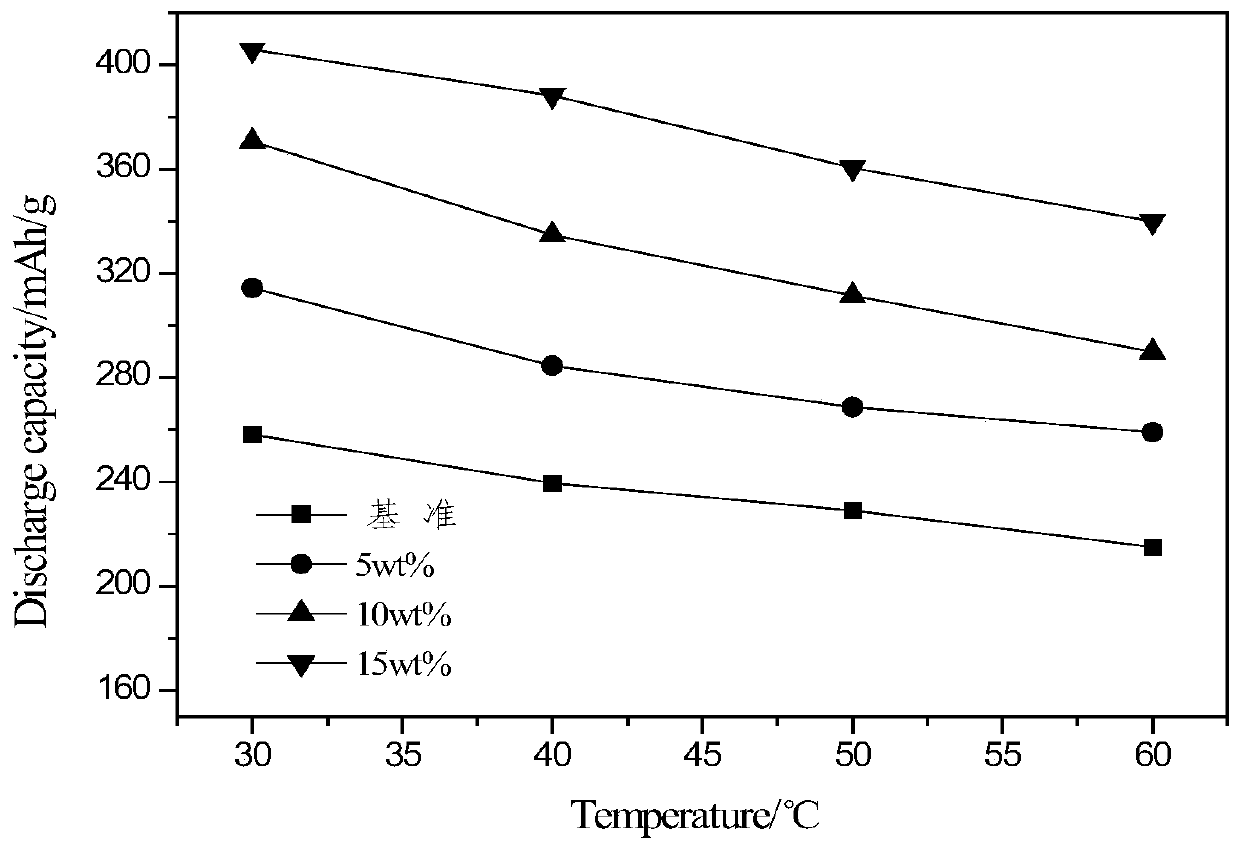

A technology of composite materials and hydrogen storage alloys, which is applied in the field of materials, can solve the problems that the discharge capacity is greatly affected by temperature and the battery’s high-rate discharge performance is poor, and achieve the effects of low cost, excellent discharge performance, and good discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Press LaY 2 Ni 9.5 mn 0.5 Al 0.5 The stoichiometric proportion of the molecular formula, La, Y, Ni, Mn, Al and other metals (purity higher than 99.9%) are placed in the melting furnace from low to high in order of melting point, and cooled and protected by circulating water In a copper crucible, it is arc smelted in an argon atmosphere, and then cooled naturally in the furnace to form an alloy ingot. In order to ensure the uniformity of the alloy, the alloy is turned over three times in the furnace, and the smelted alloy is naturally cooled and taken out. Grind it in an agate mortar and grind it, and sieve it with a 200-mesh sieve to obtain LaY 2 Ni 9.5 mn 0.5 Al 0.5 alloy powder.

[0029] Take 99.9% BFe alloy and citric acid and place them in a ball milling jar at a ratio of 1:1, then take small balls with a ball-to-material ratio of 1:15 and put them in a ball milling jar, pass protective gas argon into the ball milling jar, and place In the high-energy ball m...

Embodiment 2

[0034] Press LaY 2 Ni 9.5 mn 0.5 Al 0.5 The stoichiometric proportion of the molecular formula, La, Y, Ni, Mn, Al and other metals (purity higher than 99.9%) are placed in the melting furnace from low to high in order of melting point, and cooled and protected by circulating water In a copper crucible, it is arc smelted in an argon atmosphere, and then cooled naturally in the furnace to form an alloy ingot. In order to ensure the uniformity of the alloy, the alloy is turned over three times in the furnace, and the smelted alloy is naturally cooled and taken out. Grind it in an agate mortar and grind it, and sieve it with a 200-mesh sieve to obtain LaY 2 Ni 9.5 mn 0.5 Al 0.5alloy powder.

[0035] Take 99.9% BFe alloy and citric acid and place them in a ball milling jar at a ratio of 1:1, then take small balls with a ball-to-material ratio of 1:15 and put them in a ball milling jar, pass protective gas argon into the ball milling jar, and place In the high-energy ball mi...

Embodiment 3

[0040] Press LaY 2 Ni 9.5 mn 0.5 al 0.5 The stoichiometric proportion of the molecular formula, La, Y, Ni, Mn, Al and other metals (purity higher than 99.9%) are placed in the melting furnace from low to high in order of melting point, and cooled and protected by circulating water In a copper crucible, it is arc smelted in an argon atmosphere, and then cooled naturally in the furnace to form an alloy ingot. In order to ensure the uniformity of the alloy, the alloy is turned over three times in the furnace, and the smelted alloy is naturally cooled and taken out. Grind it in an agate mortar and grind it, and sieve it with a 200-mesh sieve to obtain LaY 2 Ni 9.5 mn 0.5 al 0.5 alloy powder.

[0041] Take 99.9% BFe alloy and citric acid and place them in a ball milling jar at a ratio of 1:1, then take small balls with a ball-to-material ratio of 1:15 and put them in a ball milling jar, pass protective gas argon into the ball milling jar, and place In the high-energy ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Maximum discharge capacity | aaaaa | aaaaa |

| Maximum discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com