Shot peening treatment method for steel product

A shot peening and product technology, applied in the direction of manufacturing tools, metal material coating processes, coatings, etc., can solve the problem of unestablished judgment, confirmation methods, and finding out whether the information on whether the compound layer is sufficiently removed is not at a practical level get usage and other issues

Active Publication Date: 2012-07-11

SINTOKOGIO LTD

View PDF11 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0017] Furthermore, molds needless to say, even in steel products including gears and coils, there is no established method of judging and confirming whether the compound layer has been sufficiently removed by shot treatment, and information on whether the compound layer has been sufficiently removed has not been established. Also not used on a practical level

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0092] Next, the present invention will be described in more detail based on examples (verification test whether to remove the compound layer).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Login to View More

Abstract

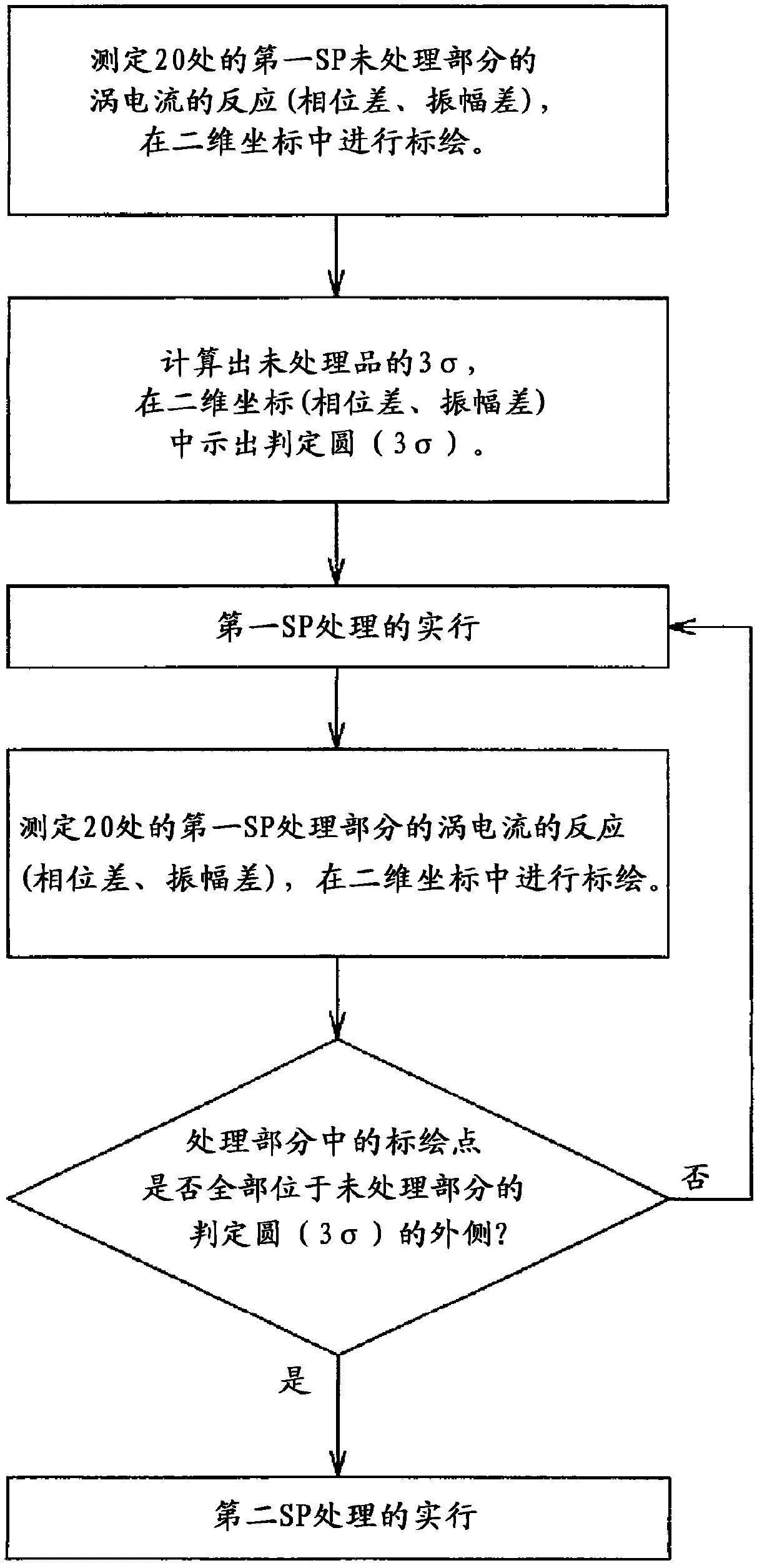

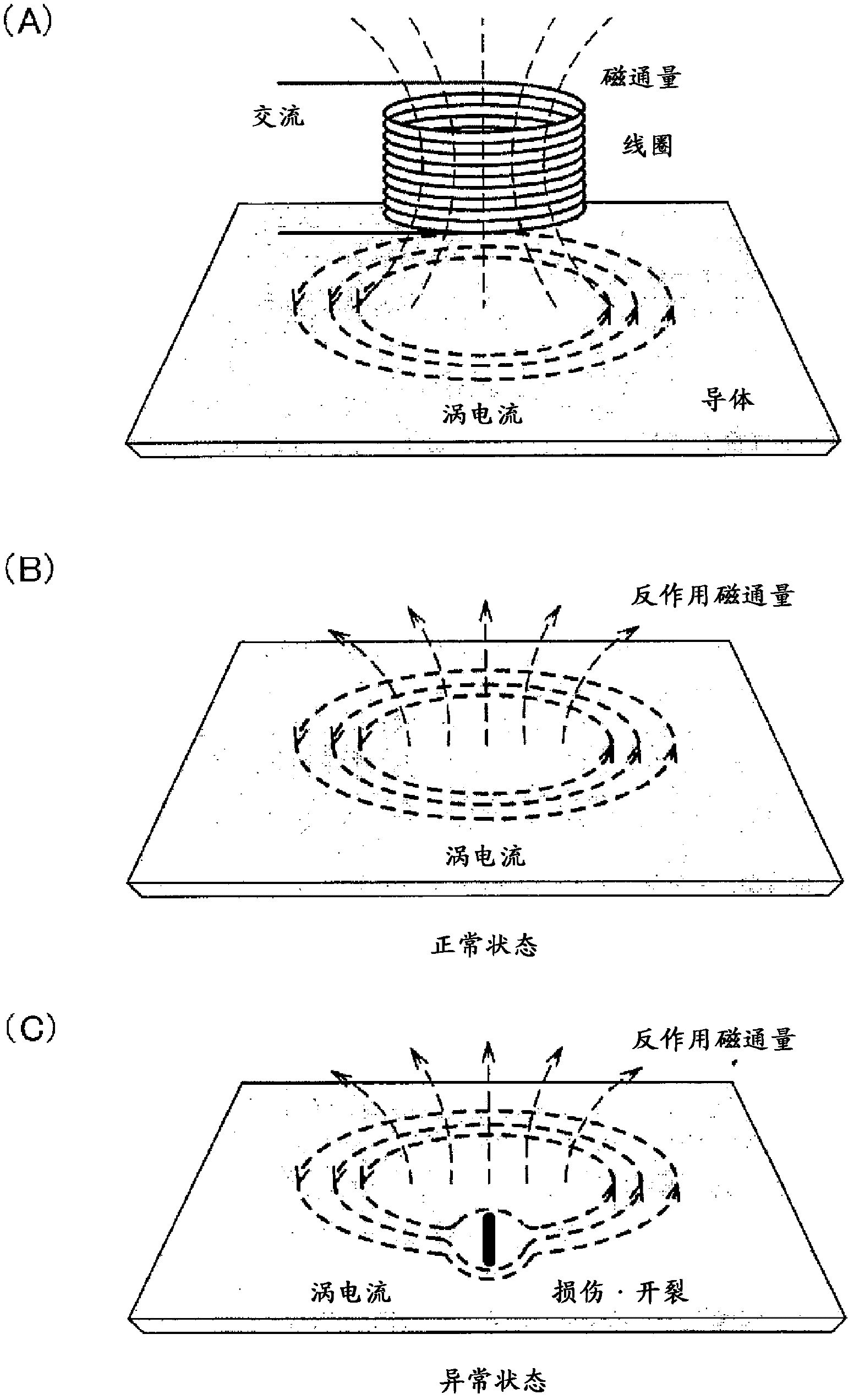

Provided is a method for performing shot peening (hereinafter abbreviated as "SP") on a treatment surface of a work piece which is a steel product that was subjected to heat hardening, the aforementioned method being such that it is possible to remarkably improve the durability (heat cycle resistance in particular) of the heat hardened surface of the aforementioned steel product. The aforementioned method for performing SP treatment on the work piece, which is the steel product subjected to heat hardening, includes a first SP treatment which removes a chemical compound layer (white layer) produced by heat hardening, as well as a second SP treatment which provides compressive residual stress to a first SP treated surface of the work piece subjected to the first SP treatment. By means of nondestructive inspection, an acceptance / rejection decision is made depending on whether or not the chemical compound layer is removed subsequent to the first SP treatment, and thereafter, the second SPtreatment is performed only on an accepted article.

Description

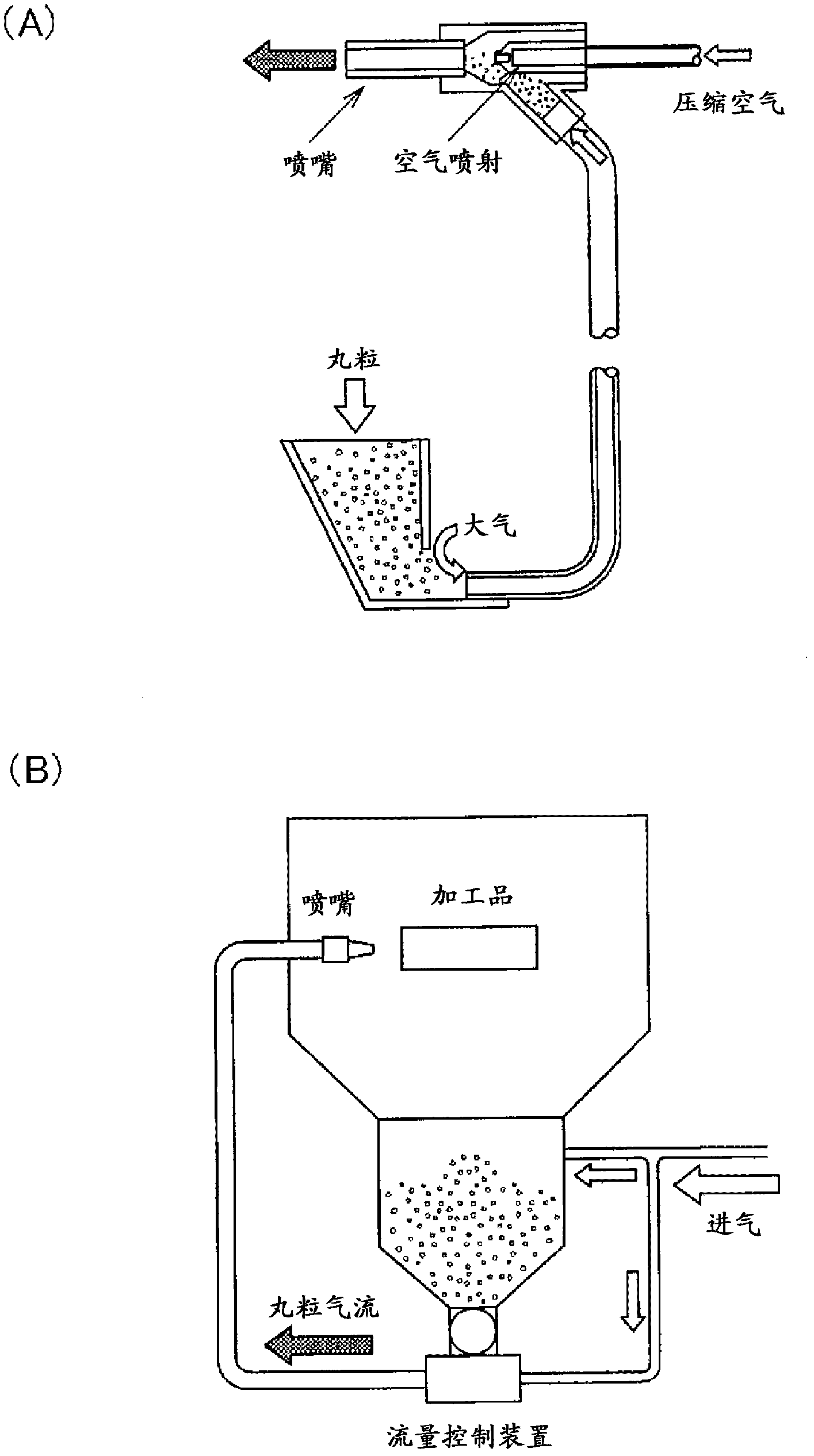

technical field [0001] The present invention relates to a shot peening method for steel products in which shot peening (hereinafter abbreviated as "SP") treatment of imparting compressive residual stress to a steel product after thermal hardening treatment, that is, a workpiece is performed. [0002] Here, as the thermal hardening treatment, a die (steel product) after nitriding treatment will be used as an example for description. In molds, especially molds for die casting of light alloys (Al, Mg), heating and cooling are repeated for each molding, resulting in the generation of small cracks (heat checks). Therefore, heat cracking resistance (thermal stress fatigue cracking resistance) and high precision are required for the shaping surface of the above-mentioned mold. [0003] However, the present invention is also applicable to other forging dies (cold and hot), and it goes without saying that it is also applicable to steel products such as gears and springs that require h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24C1/10B24C1/00C21D1/06C21D7/06C23C8/26

CPCC23C8/80C21D7/06B24C1/086B24C1/10B24C11/00C21D1/06C23C8/26

Inventor 小林祐次

Owner SINTOKOGIO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com