breech devices for hand-held firearms

A breech and firearm technology, applied in the breech mechanism, weapon accessories, firing/trigger mechanism, etc., to achieve the effect of simple structure and functional safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

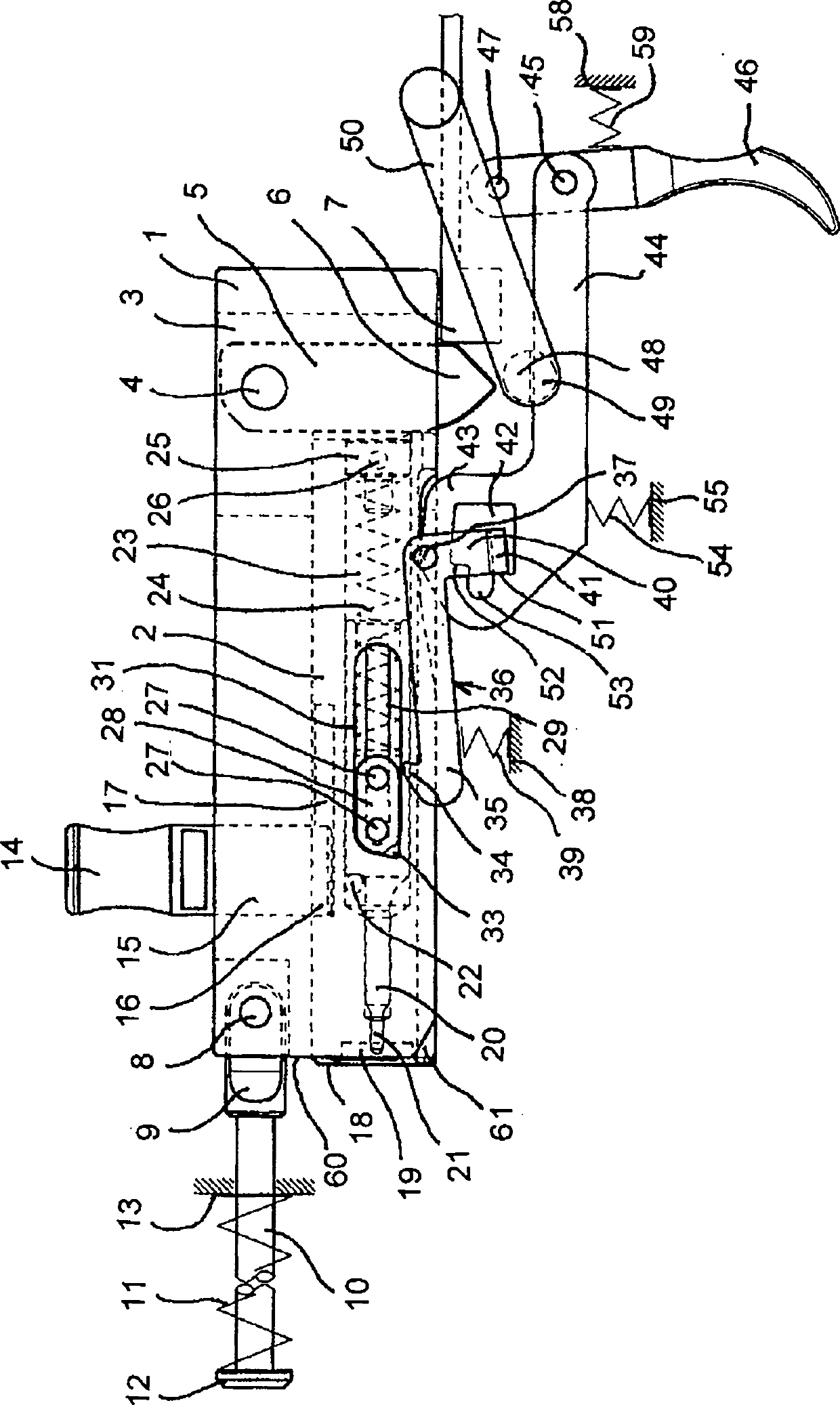

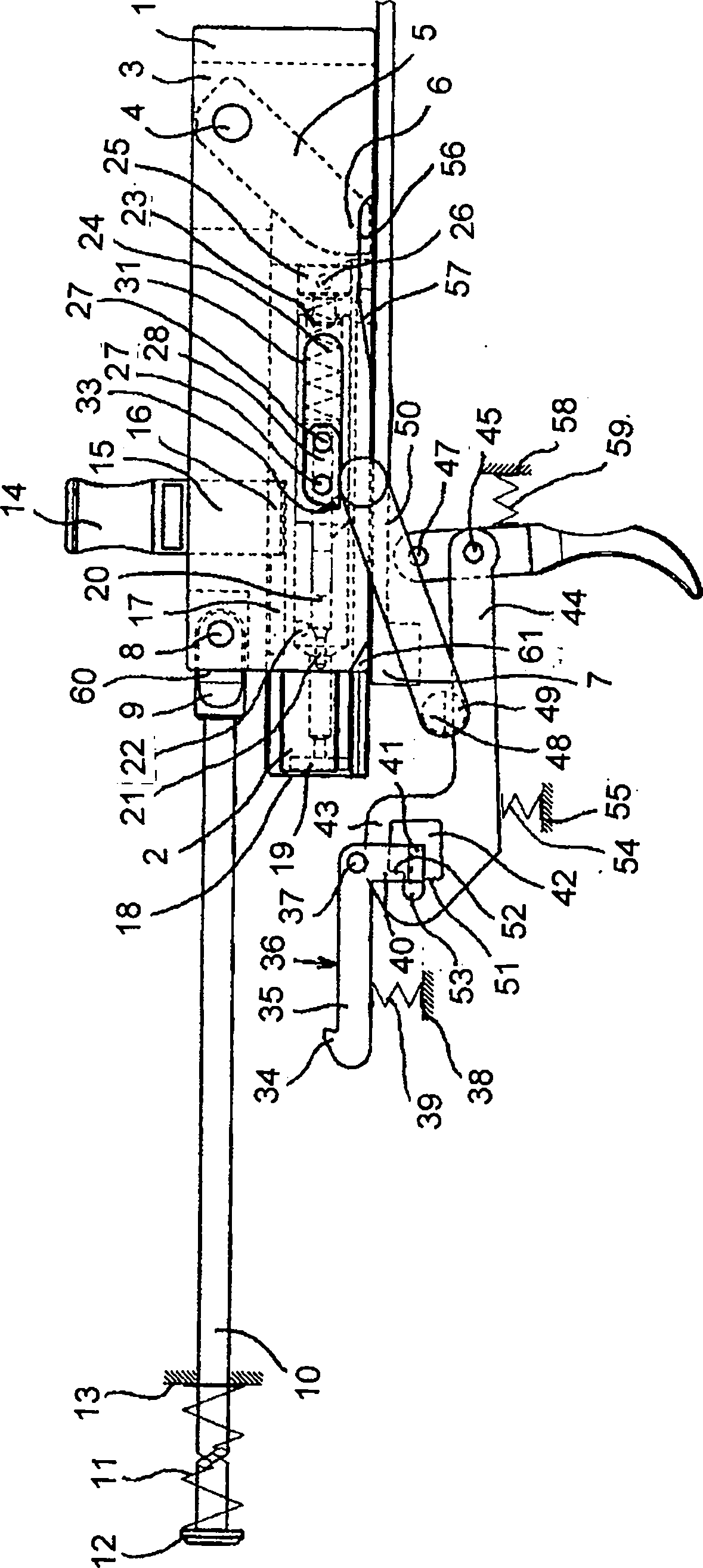

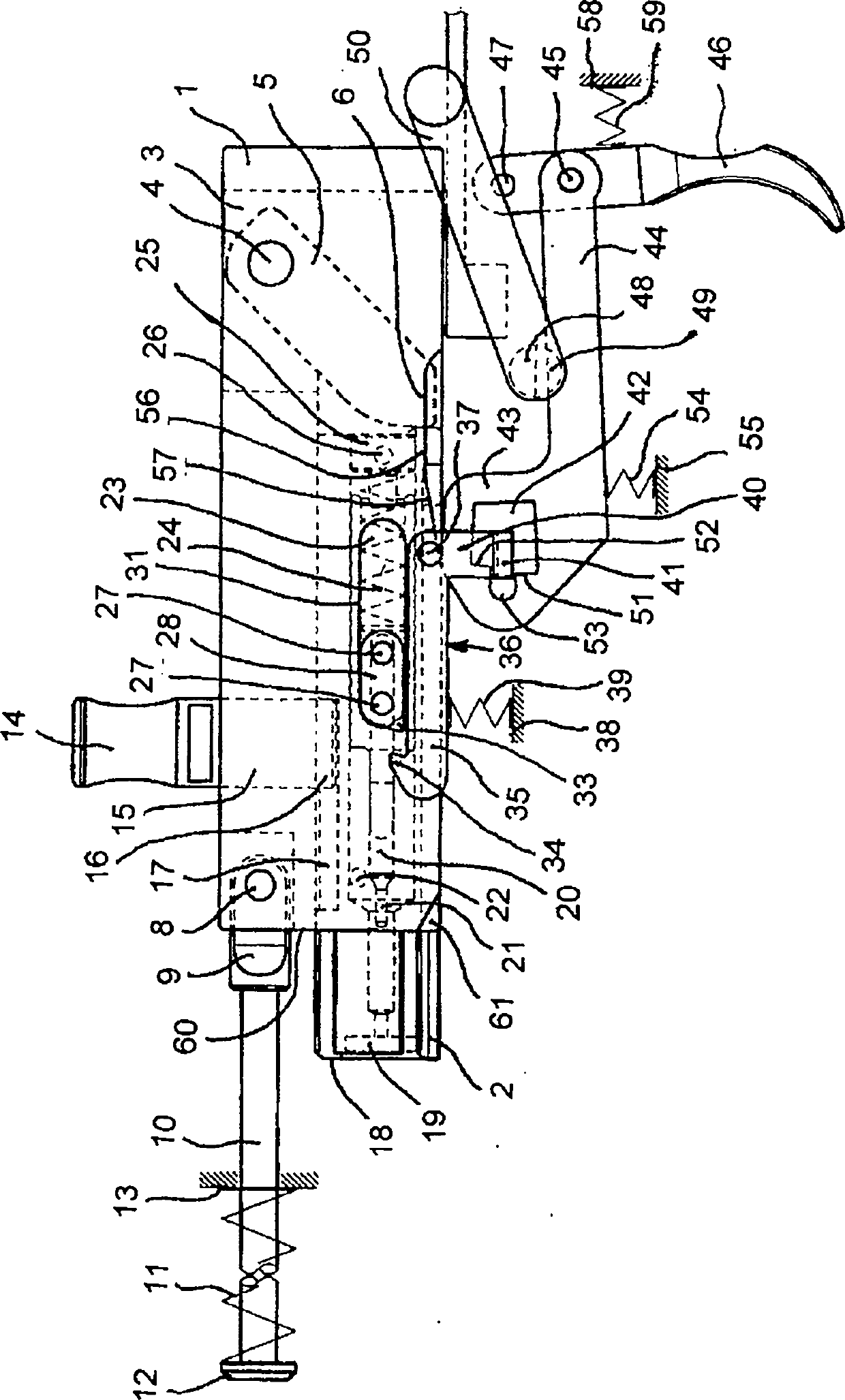

[0039] The breech device according to the invention comprises a carrier 1 slidably arranged in the housing and a breech block 2 slidably arranged in the carrier 1 . The rear part of the carrier 1 is at least partly open in the vertical direction, advantageously in the form of a well 3, inside the well 3 the locking arm 5 pivots on the support pin 4, and the free end 6 of the locking arm 5 is designed To engage with the lateral stop 7, which is a non-movable part of the firearm casing. At the front part of the carrier 1, the end 9 of the guide rod 10 is hinged on the fixed pin 8, the forward spring 11 is sleeved on the guide rod 10, and one end of the forward spring 11 is fixed at one end of the guide rod 10 by a The collar 12 bears and the other end of the forward spring 11 bears at a bearing area 13 of the firearm housing (not shown). The tensioning pin 15 is provided with a grip 14 and is vertically anchored in the carrier 1 , the end 16 of the tensioning pin 15 extending i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com