micromechanical resonator

A micromechanical resonator and resonator technology, applied in the directions of instruments, microstructure technology, electrical solid devices, etc., can solve problems such as damage to resonance performance, and achieve the effect of reducing manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

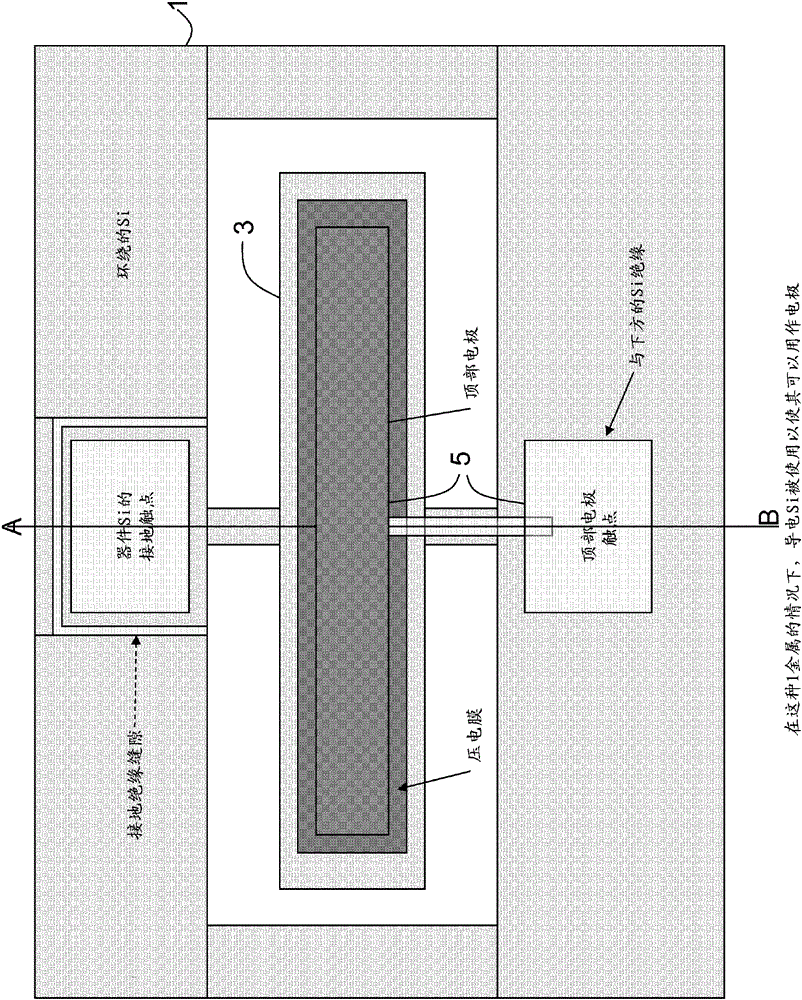

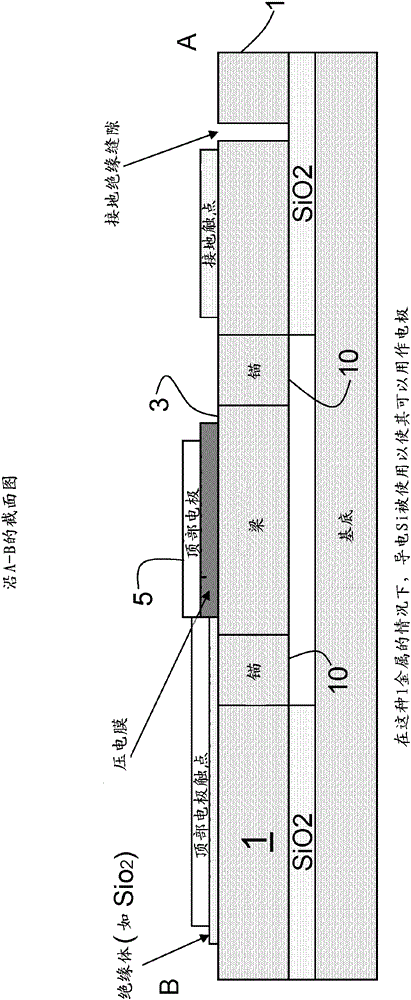

[0044] according to Figure 1 to Figure 4 , the invention relates to micromechanical structures in which a resonator 3 is suspended to a support structure 1 by means of anchors 10 . In a typical embodiment of the invention, the support structure 1 is a silicon device layer of an SOI (silicon on insulator) wafer. The dimensions and suspension of the resonator 3 are such that when the resonator 3 is excited by a corresponding electrical signal, the resonator 3 will move at a specific frequency f 0 vibration. The typical length of a beam resonator is 320 μm and its typical height is 20 μm. Excitation can be done capacitively by electrodes 5 formed on the resonator 3 and on the substrate, or alternatively, by Figure 2a or Figure 4 The piezoelectric structure is completed.

[0045] Electrical signals may be conducted to the structure through electrodes or by making the entire structure conductive to the electrical signal. Typical materials in resonators are Si for conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com