A wave stirrer for a microwave oven

A technology of agitator and microwave oven, applied in the field of microwave ovens, can solve the problems of microwave leakage, expensive manufacturing, damage to the wave agitator and the inner wall of the furnace cavity, etc., and achieves the effects of low hot spot and spark discharge danger, improved wave impedance, and low-cost production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

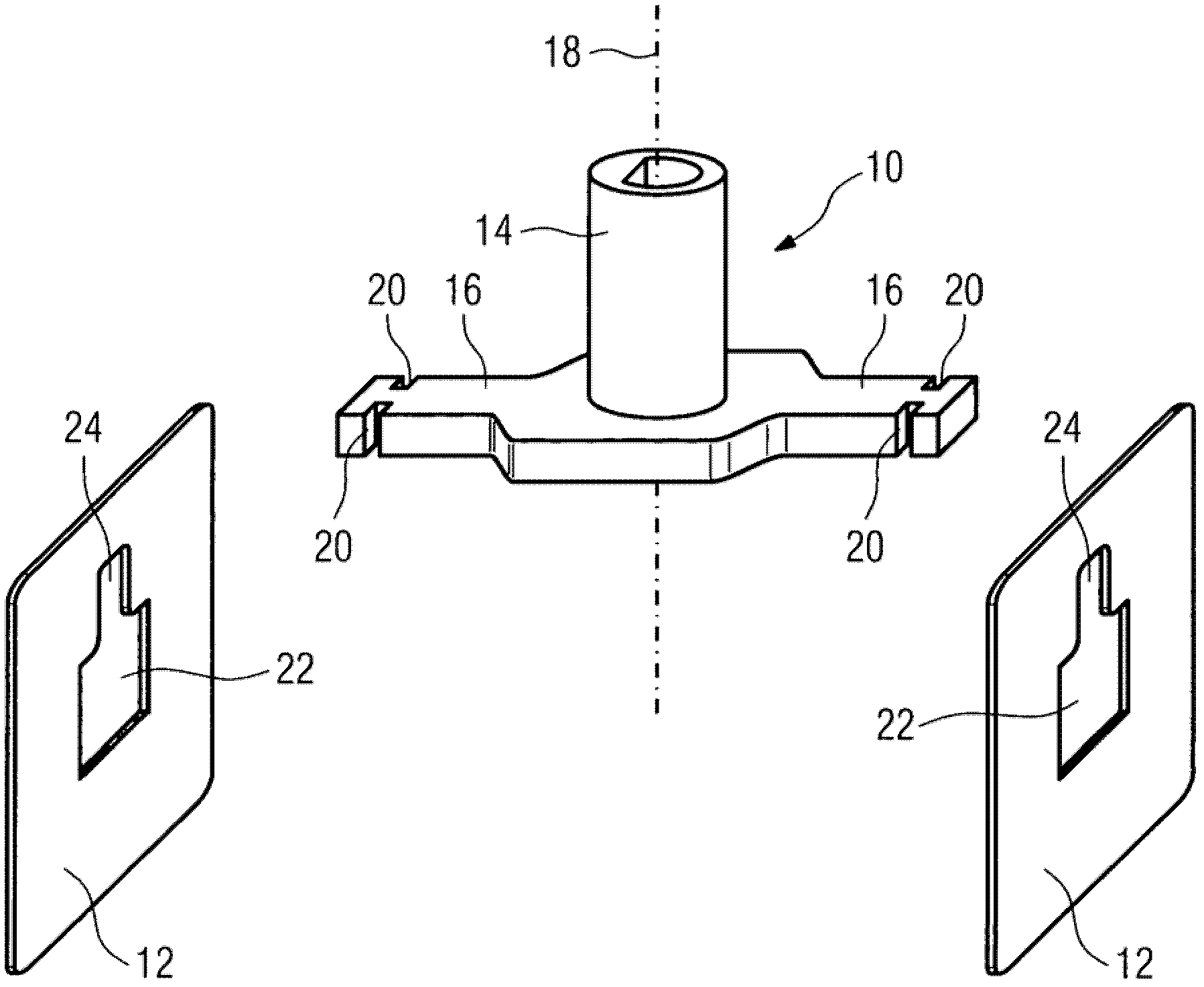

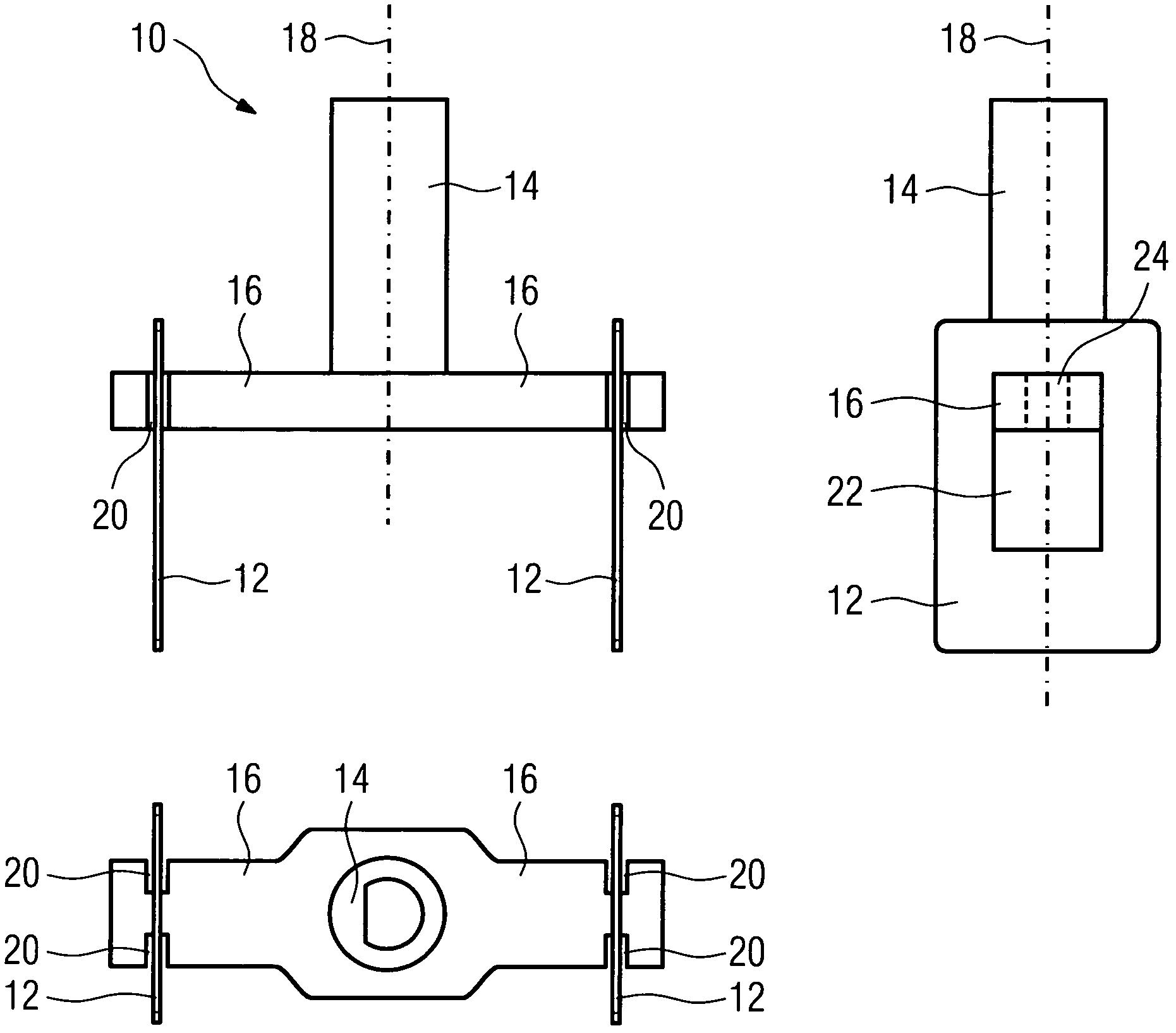

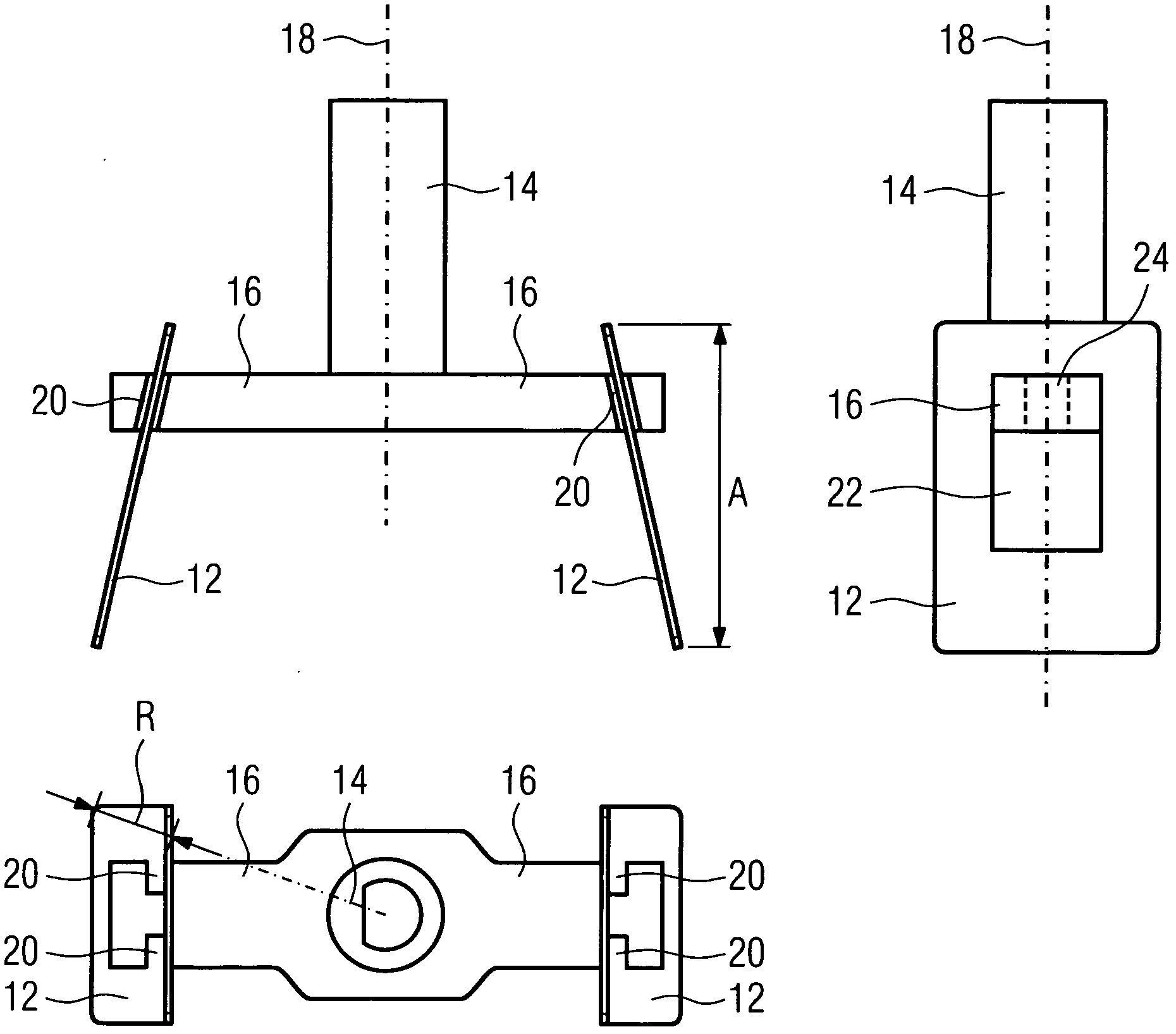

[0033] figure 1 A schematic perspective view of the wave stirrer in a disassembled state according to the first embodiment of the present invention is shown. The wave stirrer includes a holding device 10 and two stirrer blades 12.

[0034] The holding device 10 is made of a dielectric material. Preferably, the holding device 10 is made of ceramic or polymer having high temperature resistance. For example, the holding device 10 is made of LCP.

[0035] The holding device 10 includes a shaft 14 and two cantilever arms 16. The shaft 14 extends concentrically along the vertical rotation axis 18. The elongated cantilever 16 is mounted at the lower end of the shaft 14 on opposite sides of the shaft 14. The cantilever 16 extends perpendicular to the shaft 14 along the common axis. Each cantilever 16 protrudes from the rotating shaft 18 in the radial direction. In this example, the two cantilevers 16 are formed as a single piece.

[0036] The cantilevers 16 each include two mounting g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com