Double-function food purifier

A food purifier, dual-function technology, applied in food preparation, food science, home appliances, etc., can solve the problems of increasing equipment cost and energy consumption, inability to achieve thorough cleaning effectively, and low ozone solubility, so as to save energy consumption and equipment cost, food purification effect is clean and thorough, and the purification effect is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

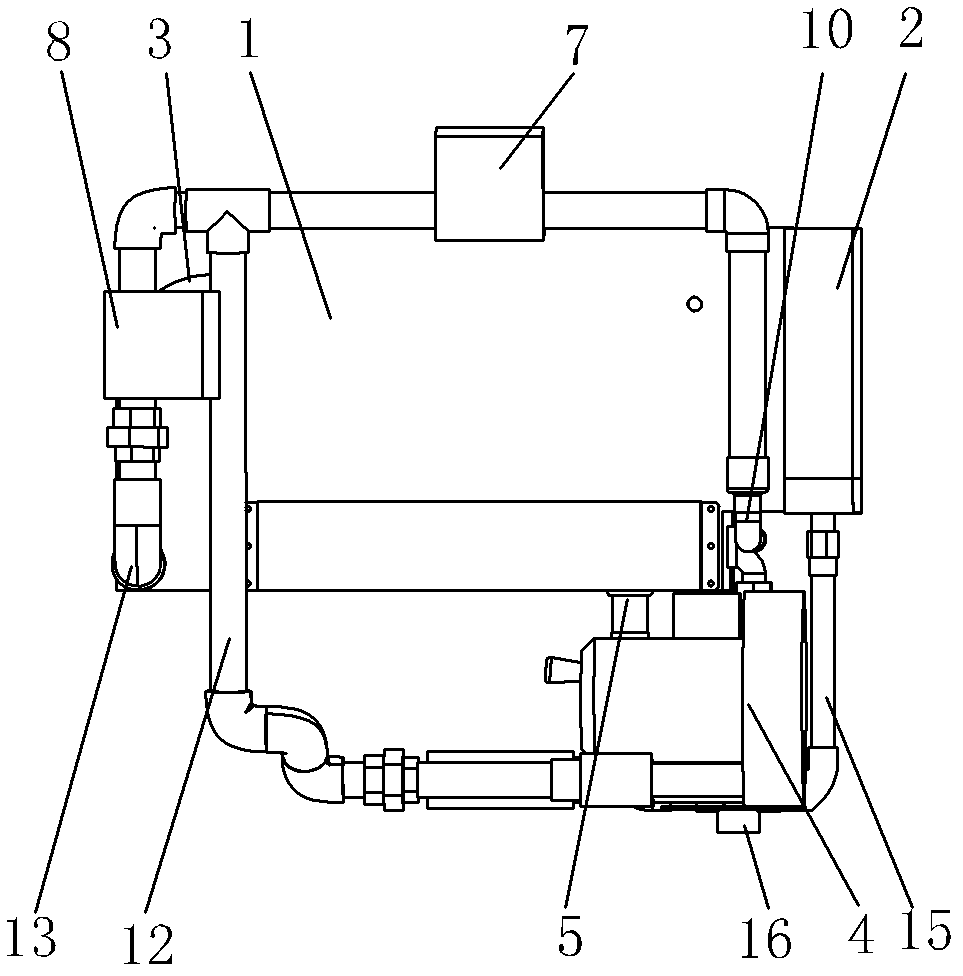

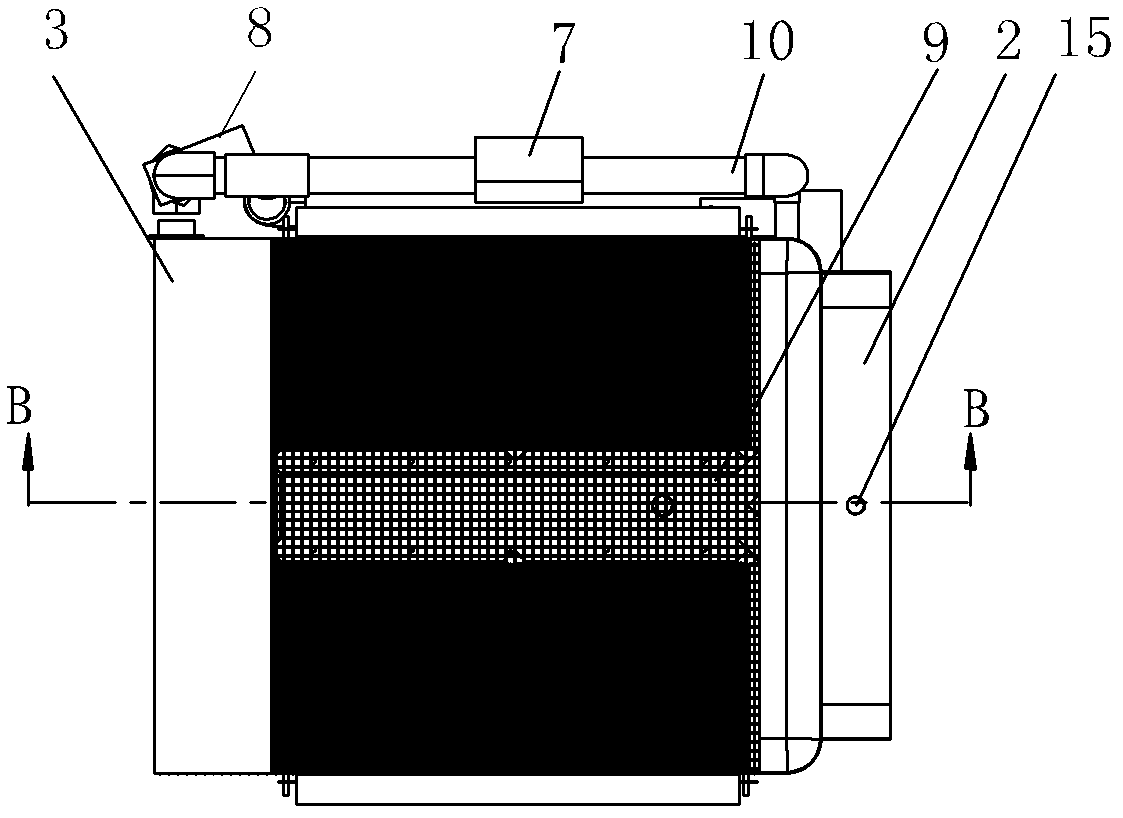

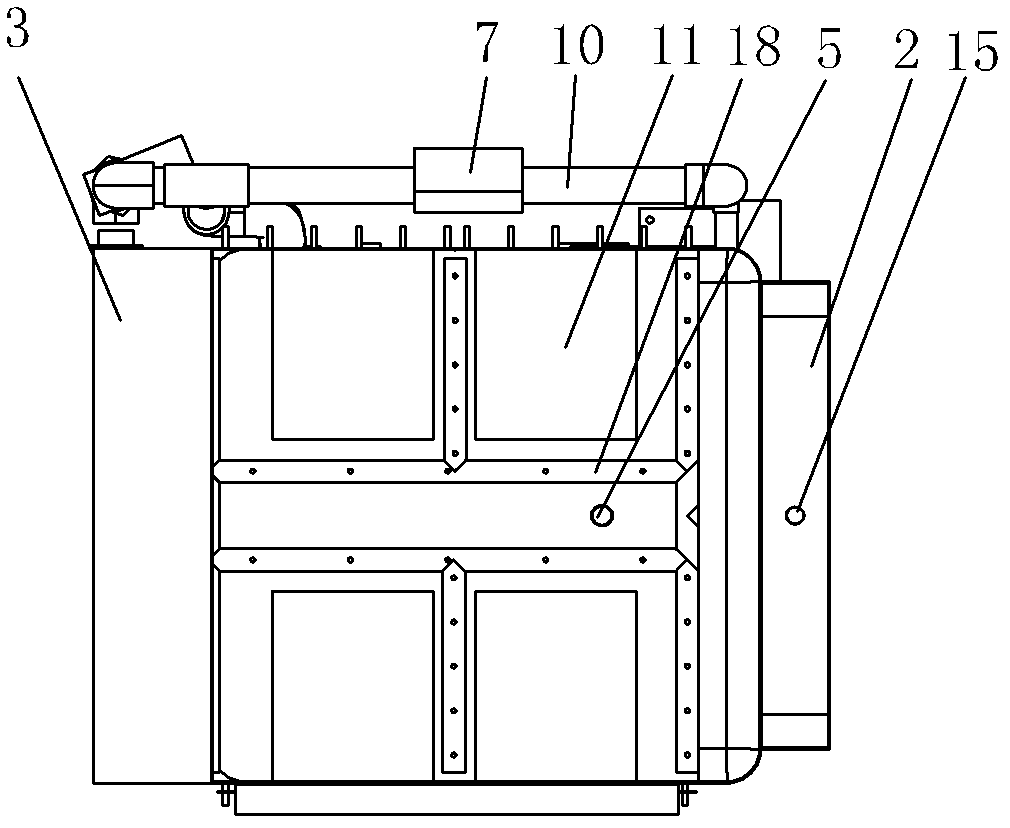

[0022] The specific implementation of the dual-function food purifier of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] like figure 1 , 2 , 3, 4, 5, 6, and 7 show the dual-function food purifier of the present invention, and the main components include a water tank 1, a water catalyst generator 11, an air pump 4, an air intake pipeline, and a drainage pipeline, wherein:

[0024] The water catalyst generator 11 is fixed at the bottom of the water tank 1. The water catalyst generator 11 is composed of multiple titanium-based sintered electrode plates. Under the condition of energization, the water flows through the gap between the electrode plates and is polarized to generate hydroxyl radicals with strong oxidation. Hydroxyl radicals enter the water tank to kill and decompose food, residual pesticides, insect eggs, bacteria, etc. on the surface of vegetables and other substances harmful to the human body. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com