Longitudinal whirlwind purification water tank

A water tank, vertical technology, applied in the field of vertical swirl purification water tank, can solve the problems of difficult control of ozone concentration, large water consumption, low ozone solubility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

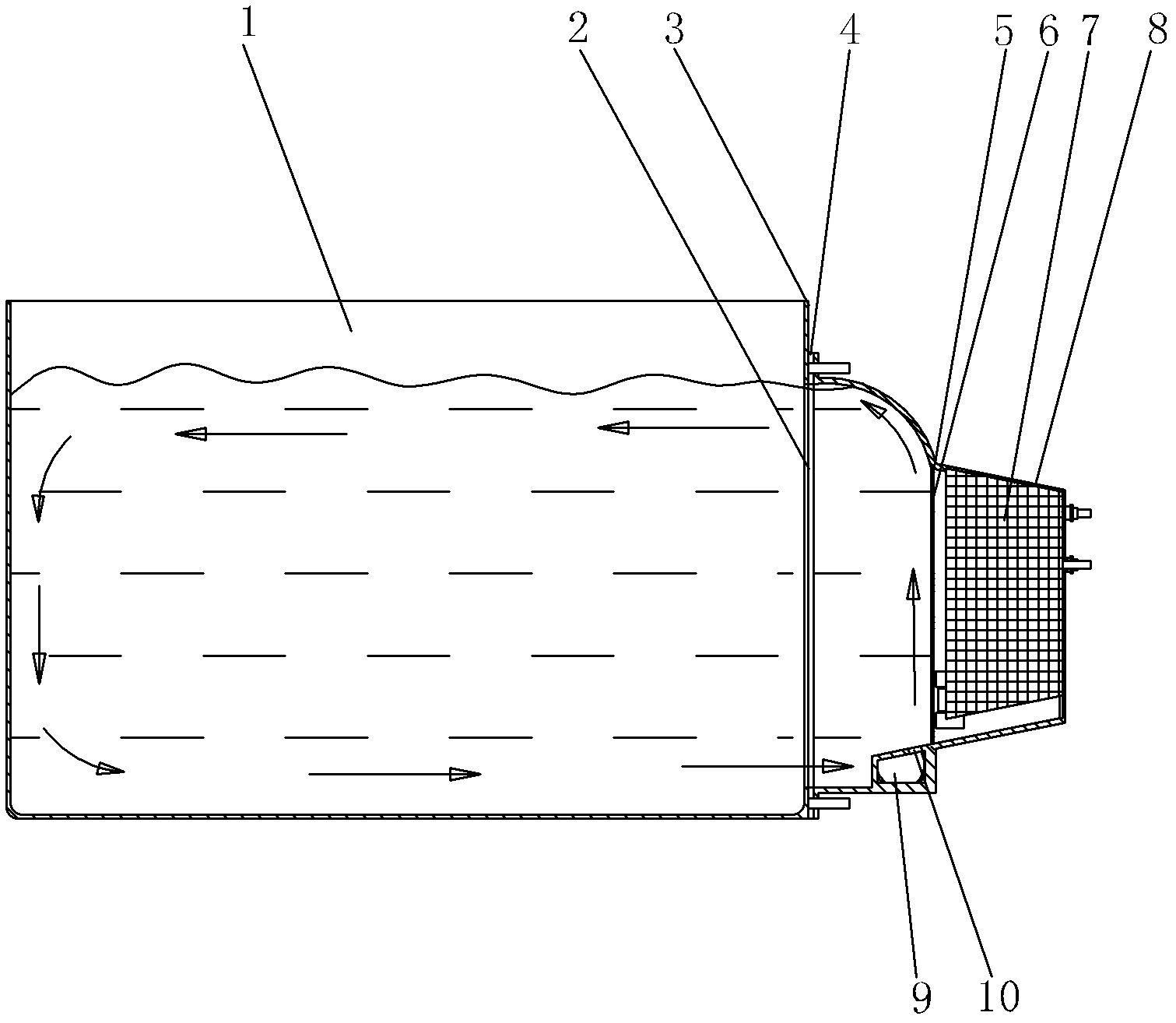

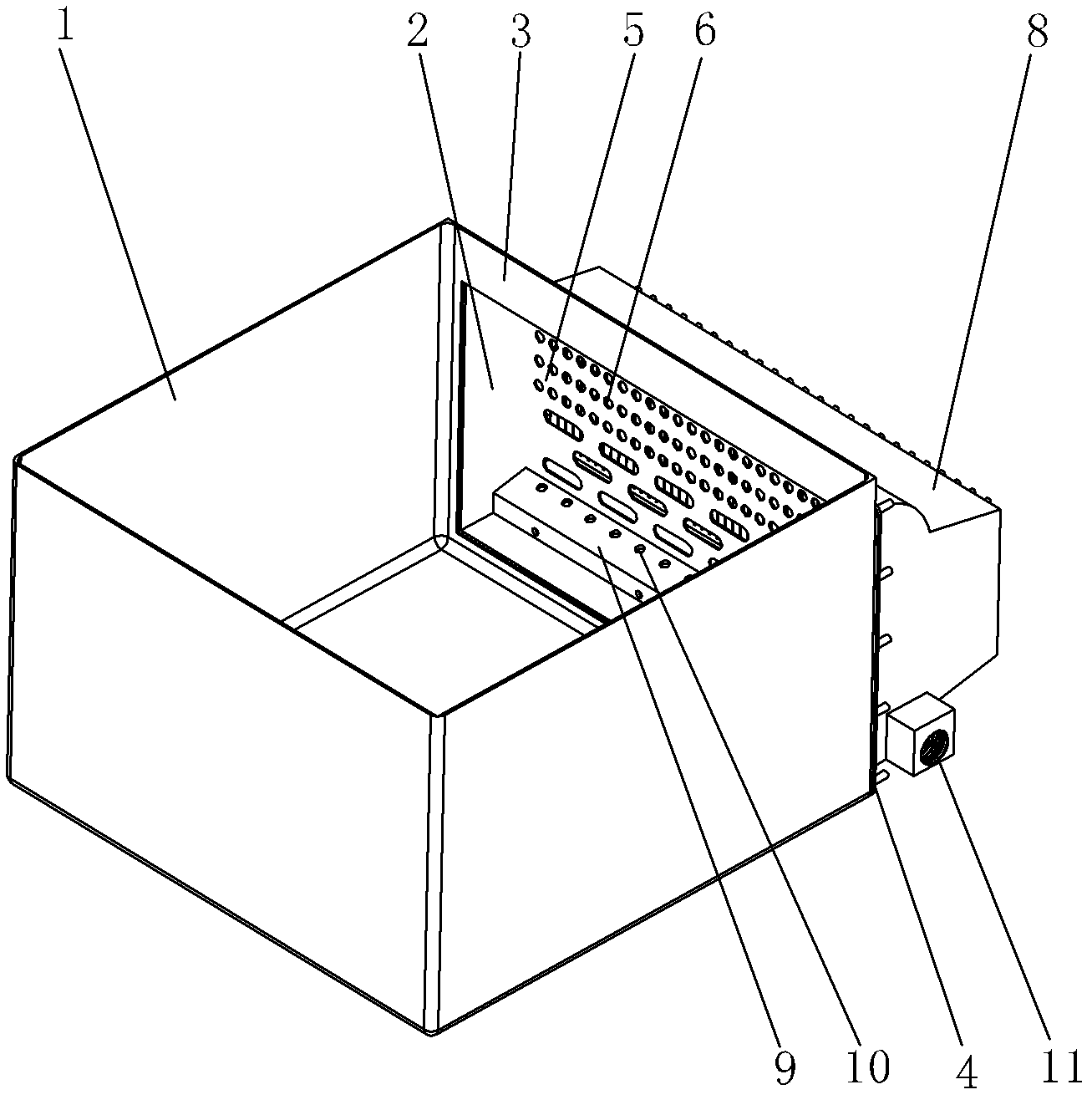

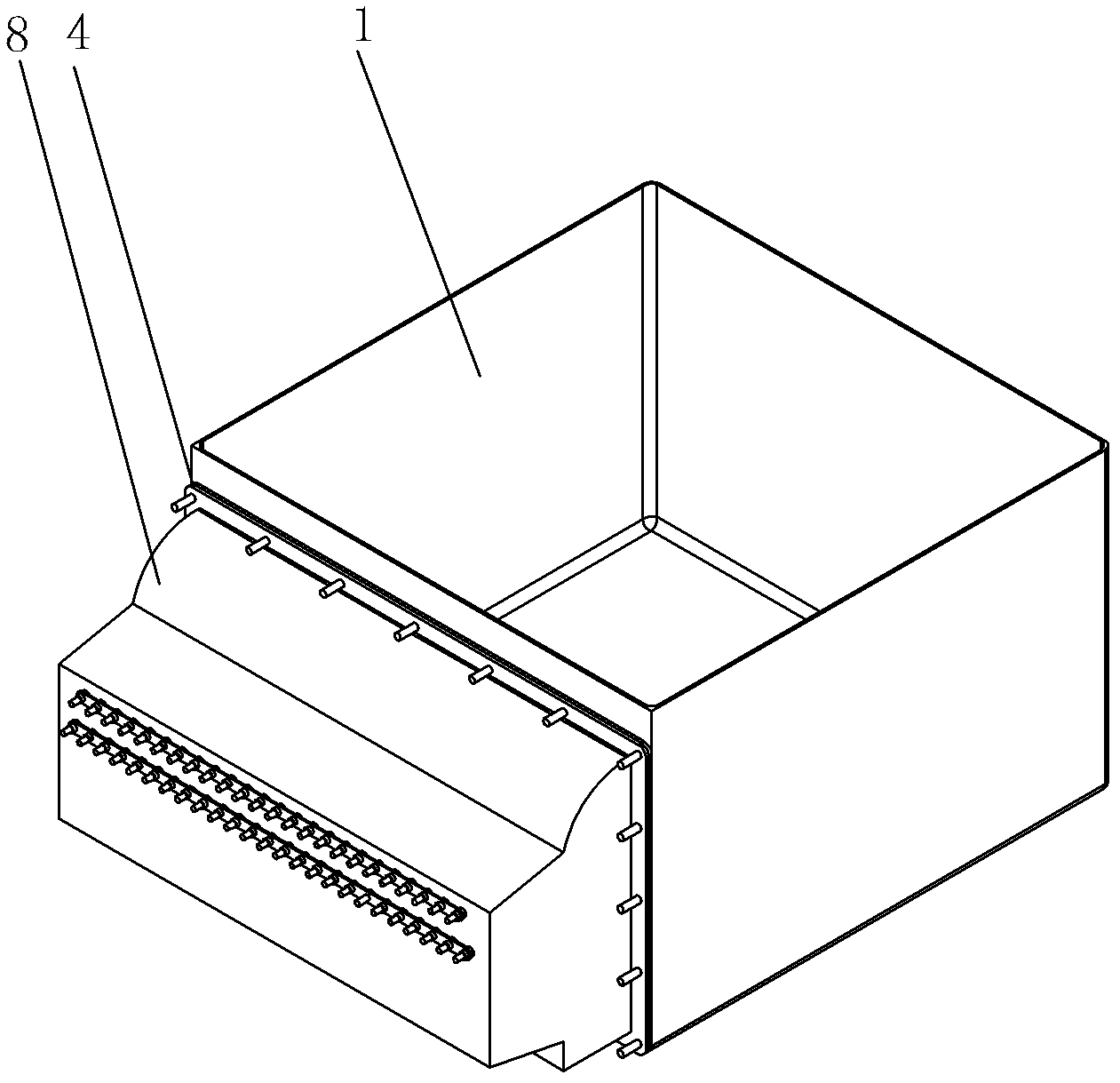

[0018] The specific implementation of the vertical swirl purification water tank of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 , 2 , 3 shows the vertical swirl purification water tank of the present invention, the main components include a water tank 1, a generator box 8 and a water catalyst generator 7, wherein: a water flow channel 2 is opened on the side wall 3 of the water tank 1, and the generator box 8 is fixed on the water tank 1 The outside of the water flow channel 2 on the side wall 3 can be welded to the outside of the water tank 1, or the generator box 8 is fixedly connected to the outside of the water tank 1 by bolts. If bolts are used, it should be on the side wall of the water tank 1. 3 and the generator box 8 use a sealing ring 4 to prevent water leakage; the porous protective plate 5 divides the generator box 8 into two compartments, and the water catalyst generator 7 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com