Overhead filter press cloth washing mechanism and double-click guiding cleaning method

A filter press, top-mounted technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of intensified rust of bottom connecting parts, unstable lifting mechanism, and unsatisfactory cleaning effect, etc. Uniform cleaning, simple structure, stable lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

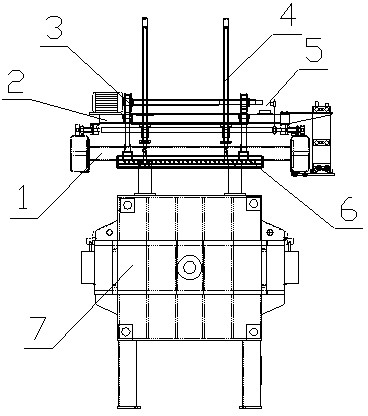

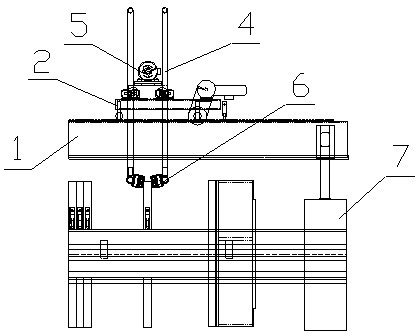

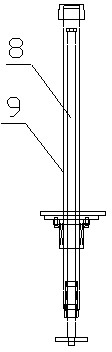

[0011] Embodiment 1: with reference to attached Figure 1~3 . A top-mounted filter press cloth washing mechanism, which includes a top-mounted support beam 1, a walking cleaning frame 2, a lifting assembly 3, a two-stage guide mechanism 4, a walking assembly 5, and a cleaning assembly 6. The above-mounted support frame 1 Fixed on the top of the filter press frame 7, the chain is matched with the driving sprocket of the walking cleaning frame 2, one end of the chain is fixed, and an adjustable tension device is installed at the other end, the lower part of the chain is padded with a PP board, and the walking cleaning frame 2 passes through the The motor of component 5 drives the sprocket to move back and forth on the upper support beam 1. The lifting component 3, the two-stage guide mechanism 4, the walking component 5 and the cleaning component 6 are all installed on the walking cleaning frame 2. The walking cleaning frame Four double-stage guide rods are installed on the 2. ...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, a two-stage guided cleaning method for the cloth washing mechanism of the upper filter press, the walking cleaning frame 2 moves back and forth on the upper supporting beam 1 under the drive of the motor of the walking assembly 5, during which Adjust the tightness of the chain through the adjustable tension device at one end of the chain, so that the running of the walking cleaning frame 2 is smooth, and the moving cleaning frame 2 reaches the middle of the filter plate under the filter press frame 7, and the plate pulling manipulator pulls a filter plate Pull to the middle of the two cleaning brushes of the cleaning assembly 6 and stop. The hoist of the lifting assembly 3 releases the cloth belt, so that the cleaning assembly 6 drives the inner guide rod 8 of the two-stage guide rod to move downward under the action of gravity. When cleaning When the component 6 reaches the upper part of the filter cloth of the filter plate, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com