Electric slide plate gate of circulating fluidized bed boiler

An electric and boiler technology, applied in the direction of windows/doors, door/window accessories, door/window applications, etc., can solve the problems of large dust, damage to the sliding door, and the failure of the travel switch to give signal control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

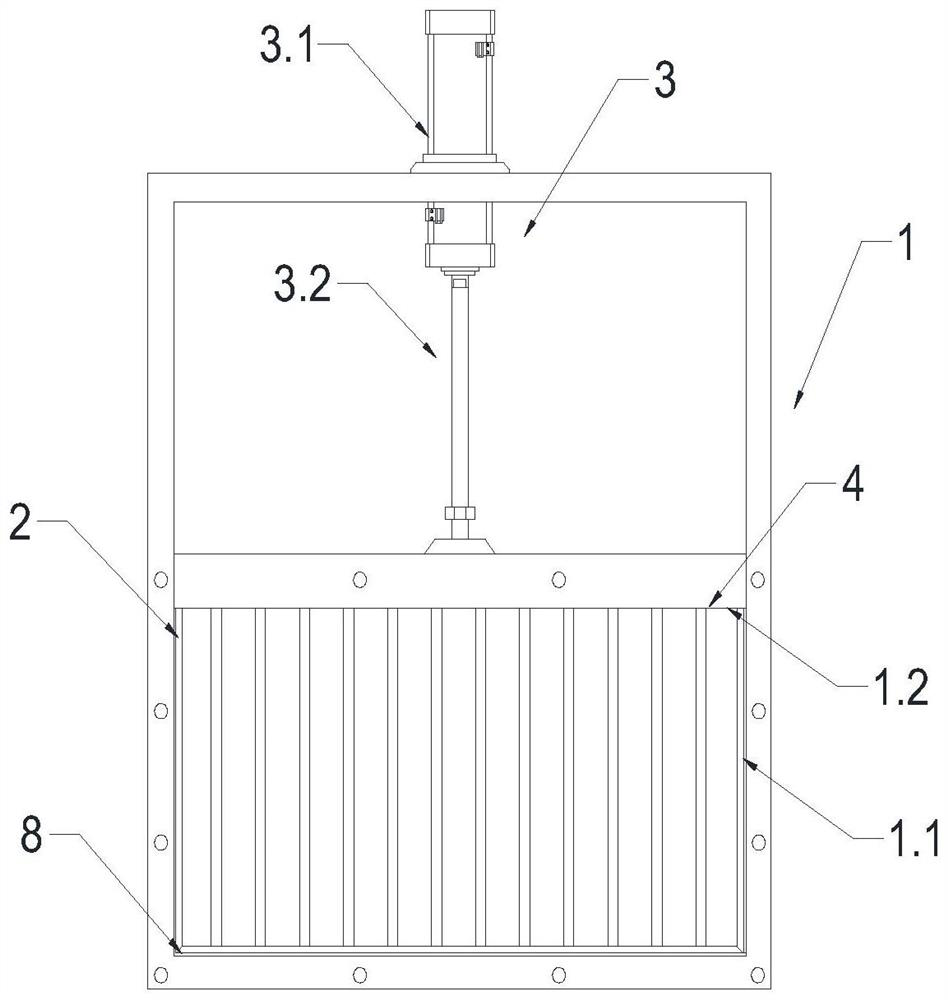

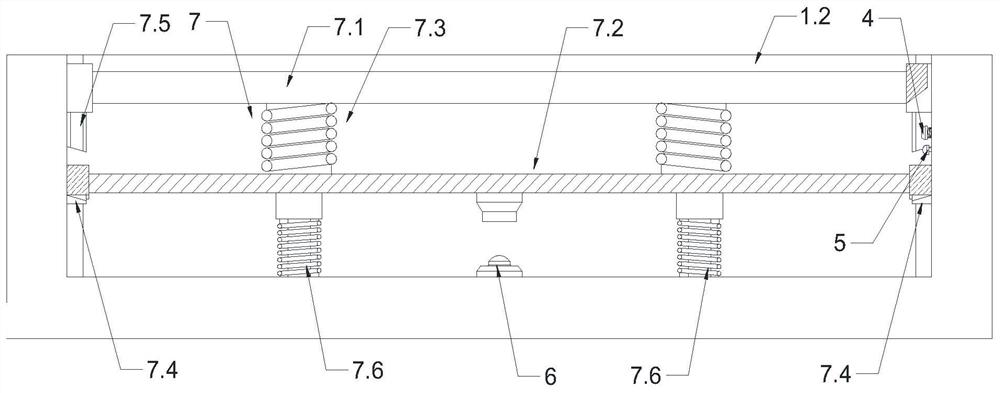

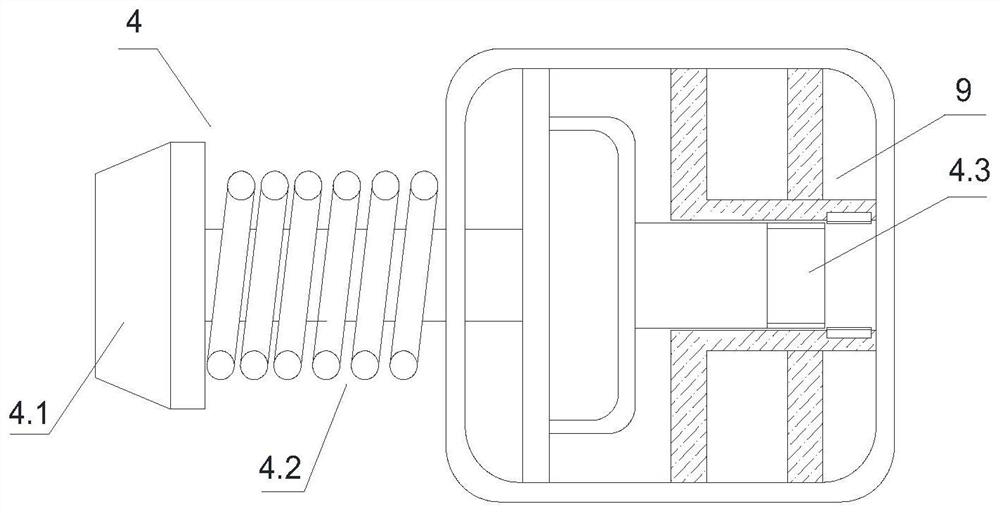

[0030] Such as Figure 1-8 As shown, the embodiment of the present invention provides an electric sliding panel door for a circulating fluidized bed boiler, which includes a door frame 1 and a door body 2. The door frame 1 is provided with a door opening 1.1, and a power device 3 drives the door body 2 to close the door. The reciprocating movement on the frame 1 is to open and close the door opening 1.1. The door frame 1 is provided with a travel switch and also includes a mechanical linkage mechanism 4. The door frame 1 is provided with the power input end of the mechanical linkage mechanism 4, and the power output of the mechanical linkage mechanism 4. Terminal is connected on the mechanical switch 9 of power unit 3.

[0031] Specifically, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com