A continuous production line waste water recycling control device

A technology for the production of waste water and control devices, which is applied in the direction of electrical program control and comprehensive factory control, etc. It can solve the problems of not being able to know whether the pump is running normally, spare parts such as the pump body and mechanical seal are heating, and the height difference is large, so as to reduce Fault occurrence frequency, fault repair and maintenance cost reduction, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

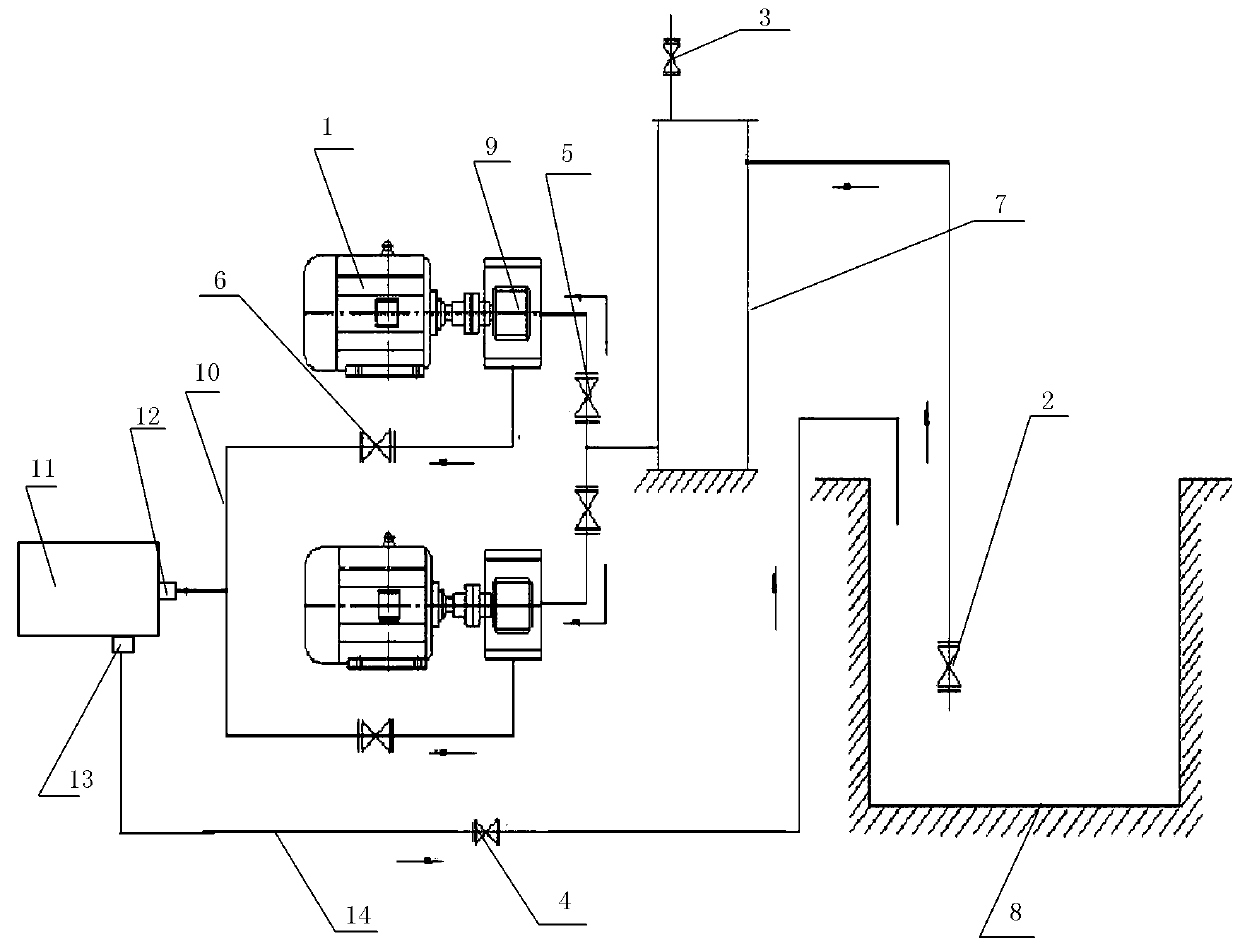

[0008] Embodiment one, in figure 1 Among them, the present invention provides a continuous operation line production waste water recovery control device, which is provided with several motors 1, several self-priming pumps 9 and water storage buckets 7, the water storage buckets 7 are set as PP water storage buckets, and the motor 1 is set as frequency conversion Motor, the present embodiment is provided with two motors 1 and two self-priming pumps 9, wherein one motor 1 and one self-priming pump 9 are in use, and another motor 1 and another self-priming pump 9 are standby state, each motor 1 corresponds to each self-priming pump 9, each motor 1 is connected to each self-priming pump 9, and the water inlets of the two self-priming pumps 9 are connected to the water outlet of the water storage tank 7 , the water outlet of each self-priming pump 9 is connected to the water inlet 12 of the sewage station 11 through the water outlet pipe 10, and the water outlet pipe 10 connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com