Evacuation apparatus

An evacuation device, gas technology, used in liquid variable volume machinery, liquid fuel engines, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

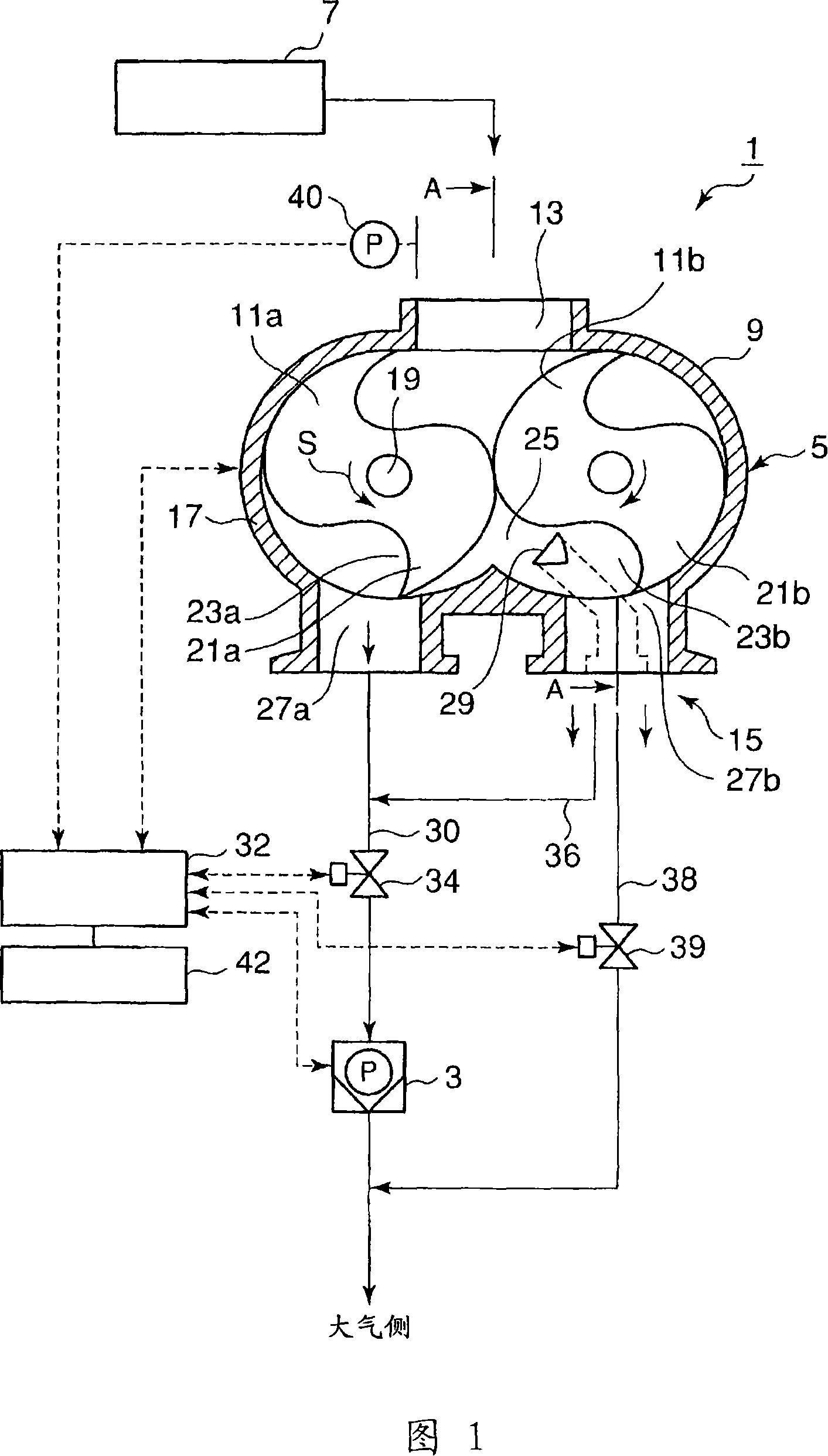

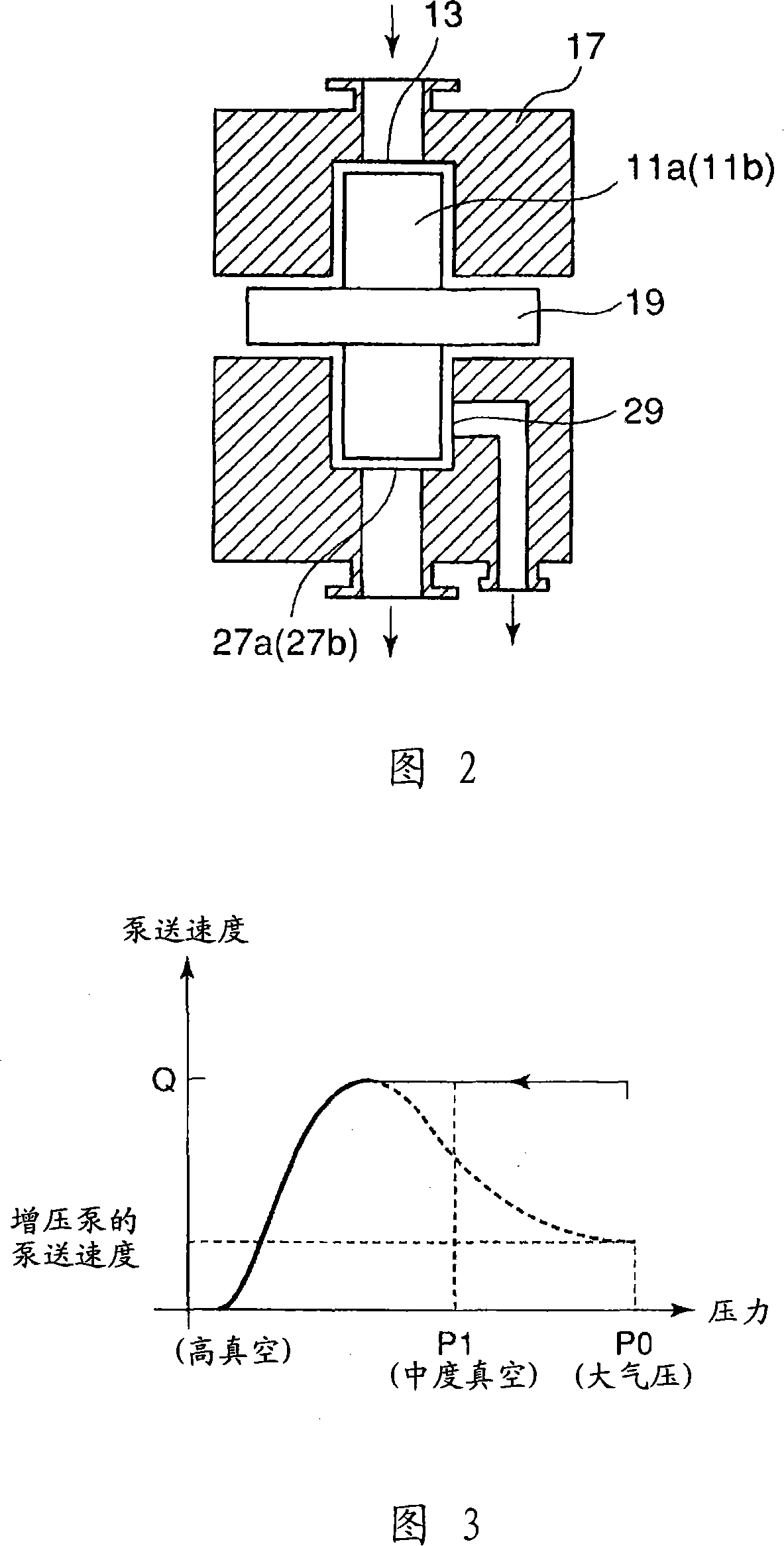

Method used

Image

Examples

no. 2 example

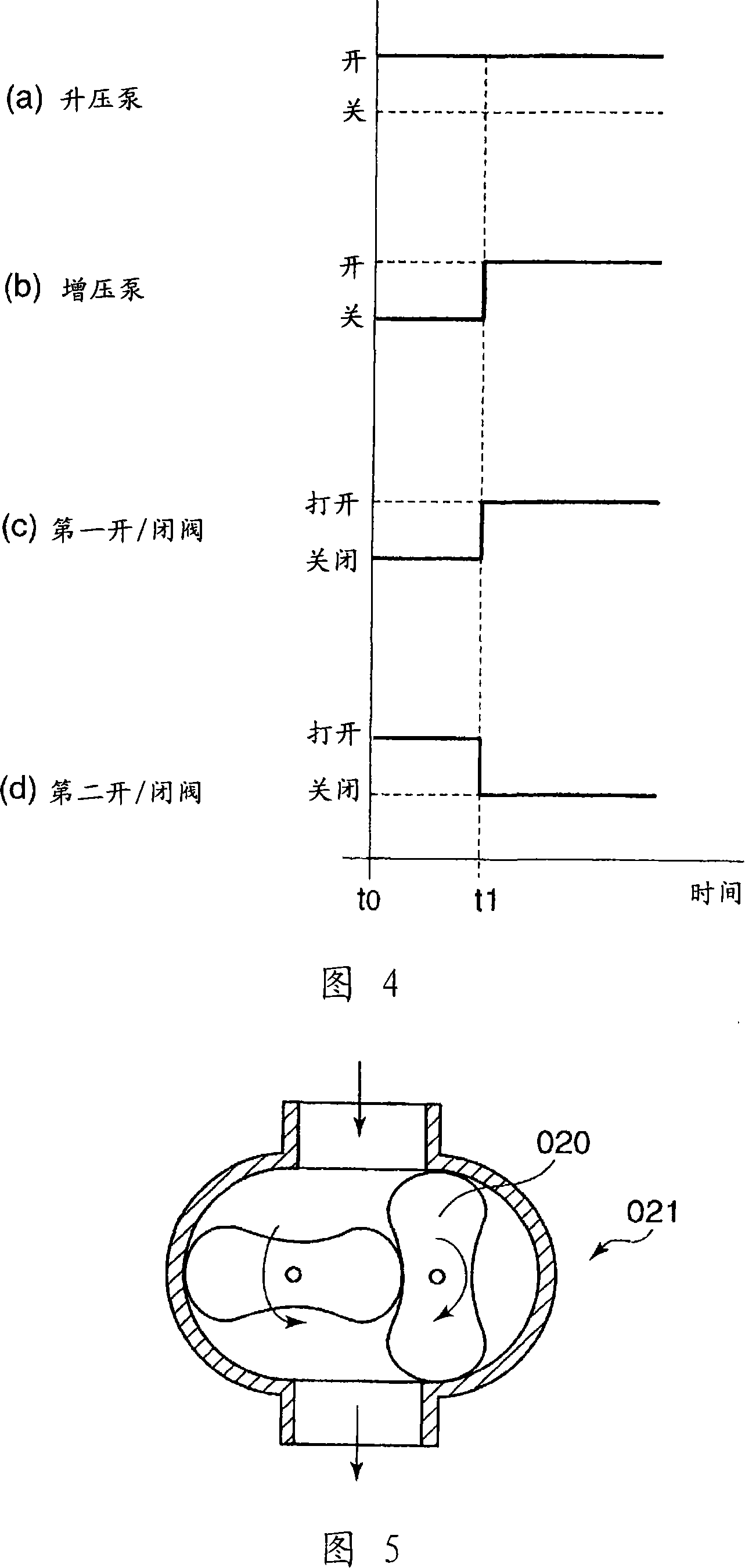

[0052] Then, a second embodiment will be described.

[0053] In this second embodiment, the elapsed time signal from the timer 42, rather than the pressure signal from the pressure sensor 40, switches the on / off state of the pumps 5 and 3, and also the on / off valve 34 and 39 on / off state conversion.

[0054] The time t1 is predetermined by calculation based on conditions such as the volume of the vacuum tank 7, the discharge capacity of the compression space 25 of the mechanical booster pump 5, specific operating factors of the mechanical booster pump 5, ambient temperature, etc. t1 is the time required for pressure P0 to drop to pressure P1 (medium vacuum).

[0055] When the controller recognizes that the time t1 has passed the time t0 through the signal from the timer 42, the controller controls the operating state so that the mechanical booster pump 5 is in the on state, the booster pump 3 is in the on state, and the first on The on / off valve 34 is in an open state, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com