Material layer extruding energy-saving grinding apparatus

A grinding and material layer technology, applied in the field of material layer extrusion energy-saving grinding equipment, can solve the problems of high grinding efficiency, low energy consumption, inapplicability, etc., to save maintenance costs, reduce working pressure, and easy material selection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

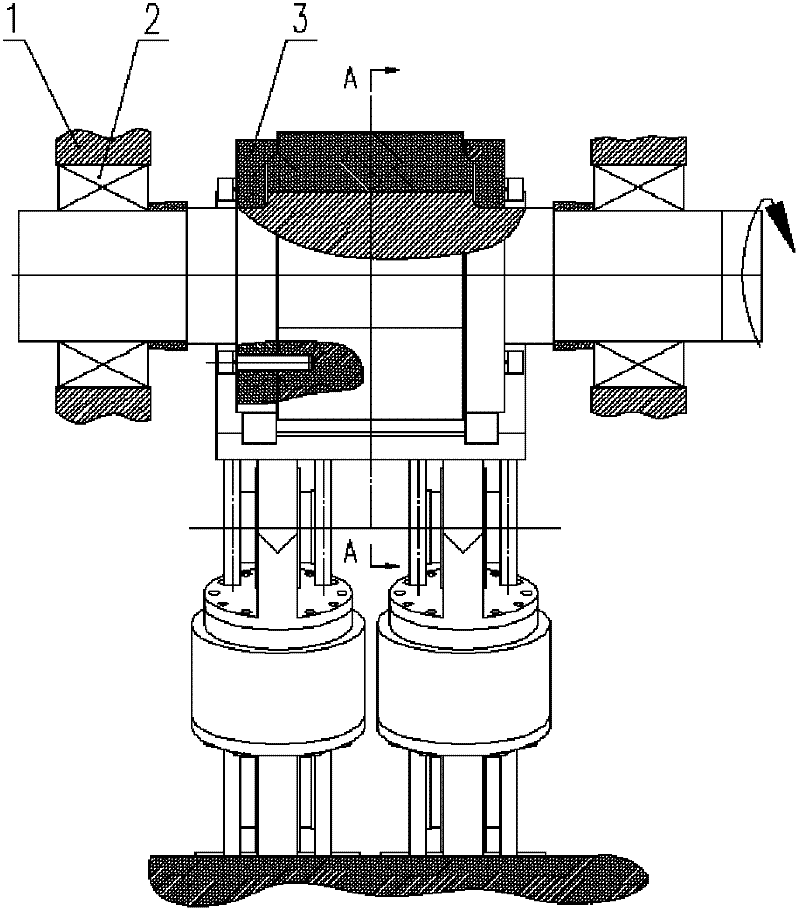

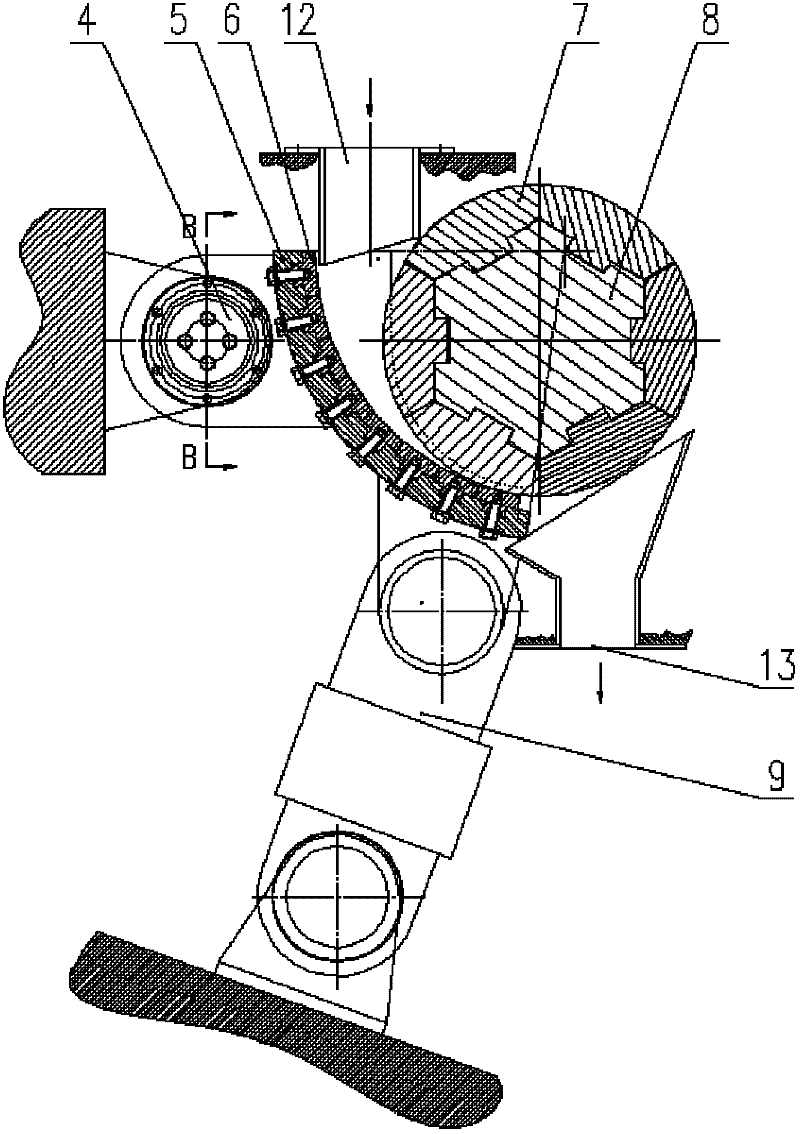

[0025] See Figure 1 ~ Figure 5 , A material layer extrusion energy-saving grinding equipment, including suspension device 4, arc-shaped support plate 5, lining plate 6, side baffle 11, pressure device 9, roller shaft 8, roller sleeve 7, drive device, inlet The material device 12, the material device 13, and the frame 1.

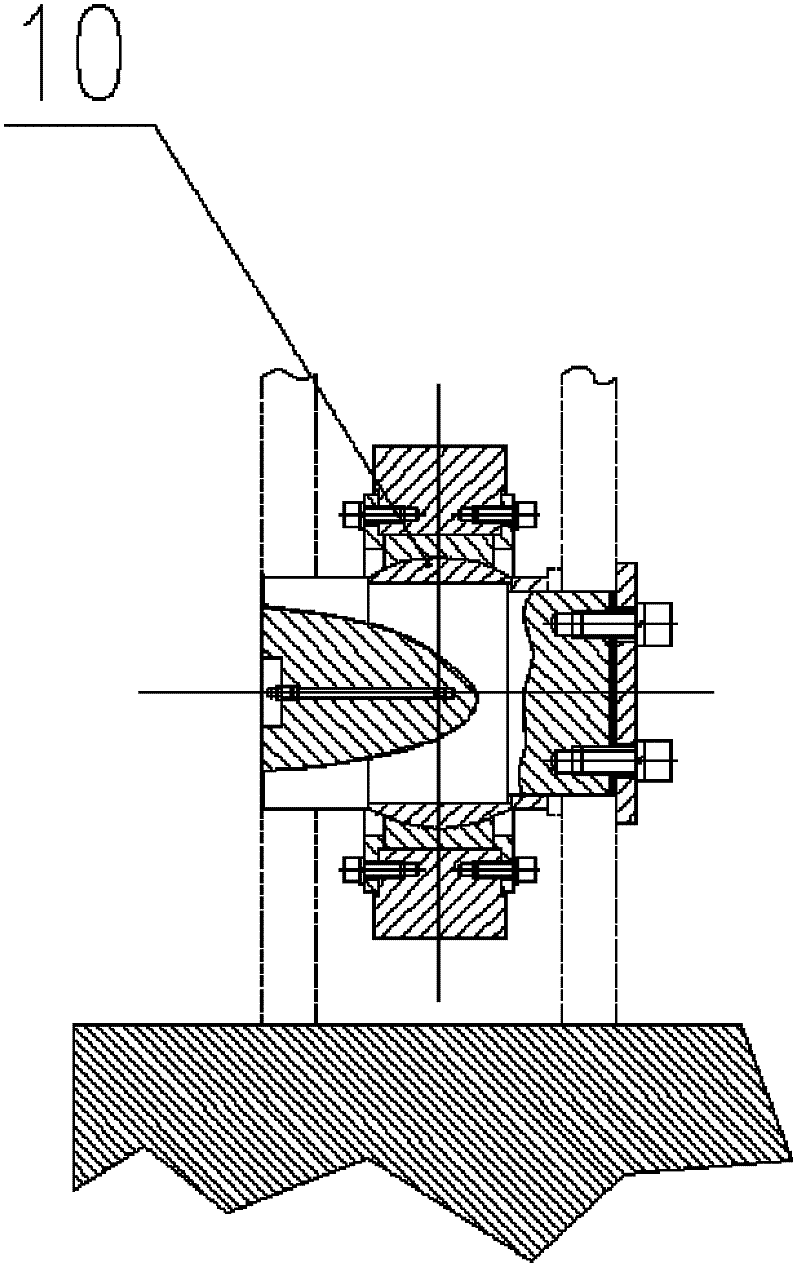

[0026] The outer surface of the arc-shaped support plate 5 is provided with an upper lifting lug and a lower lifting lug. The upper lifting lug is connected with the pin on the frame 1 through the joint bearing 10 in the suspension device 4, and the lower lifting lug is connected to the pin on the frame 1 through the pressurizing device. The joint bearing is connected to one end of the pressurizing device 9, and the other end of the pressurizing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com