Machine frame of battery pole piece rubbing mill

A battery pole piece, rolling mill technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of the reduction of the rigidity and stability of the stand, the unbalanced stress distribution of the stand, and the elastic deformation. Non-uniformity and other problems, to achieve the effect of improving production adaptability, balanced stress distribution, and protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

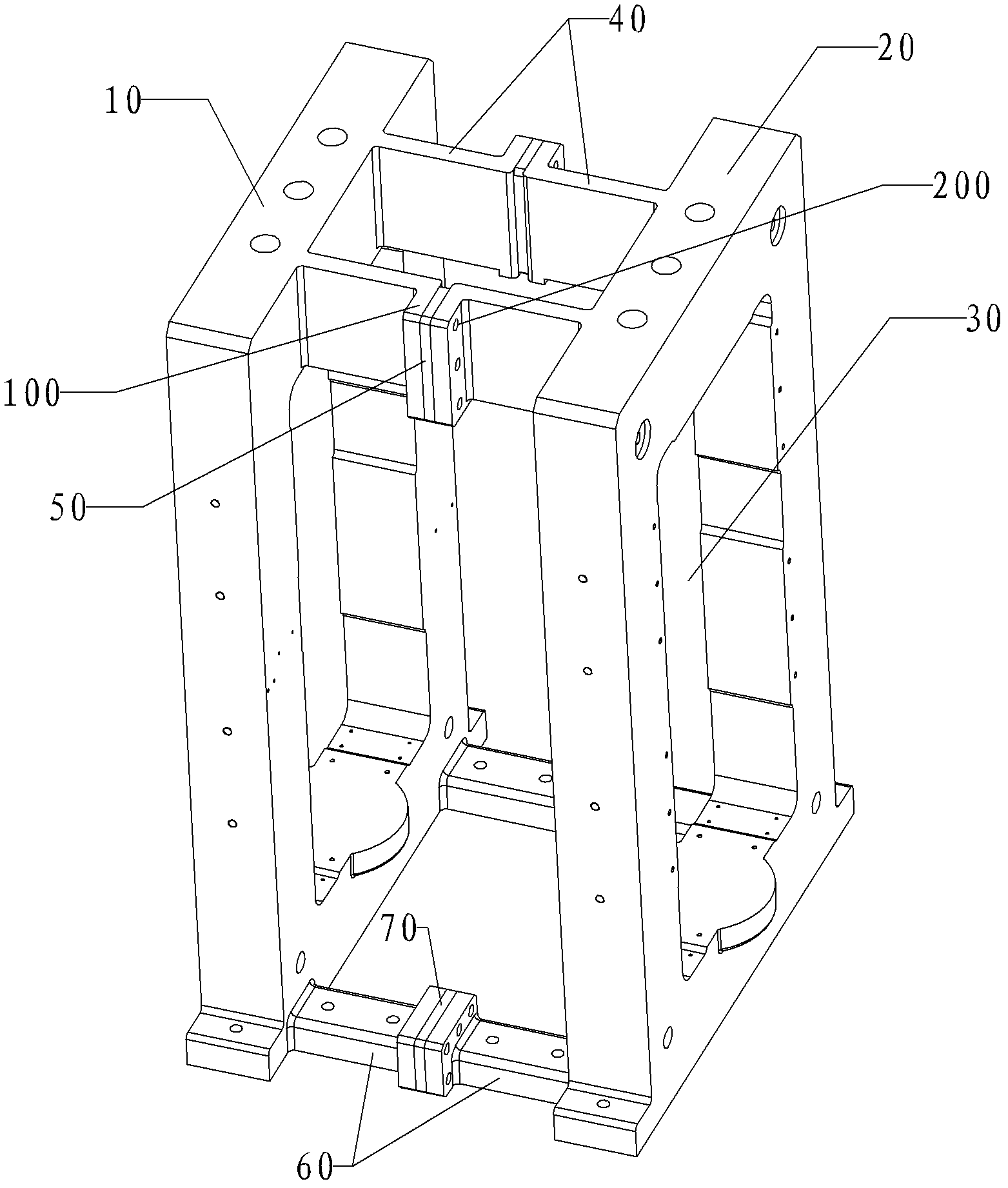

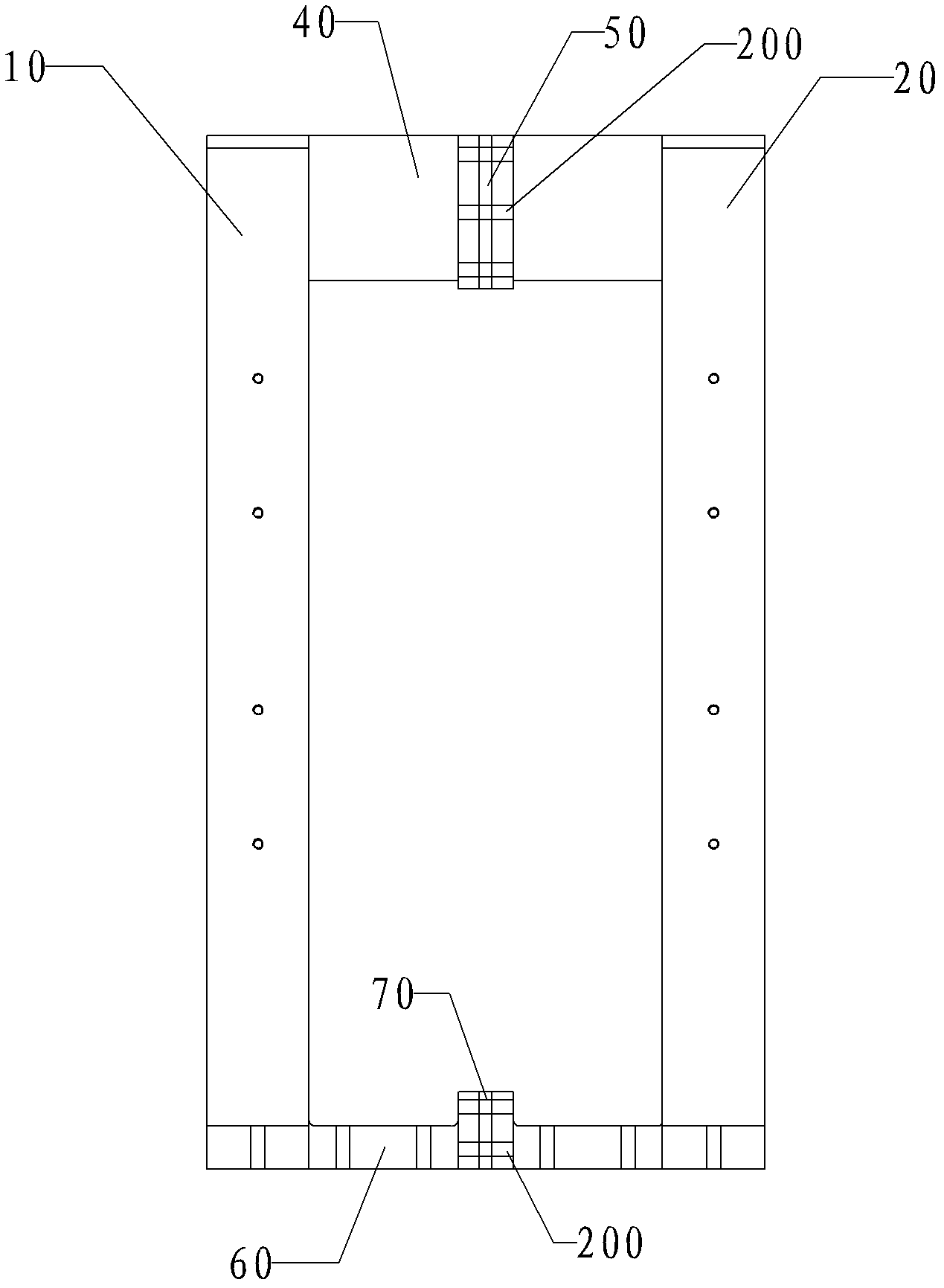

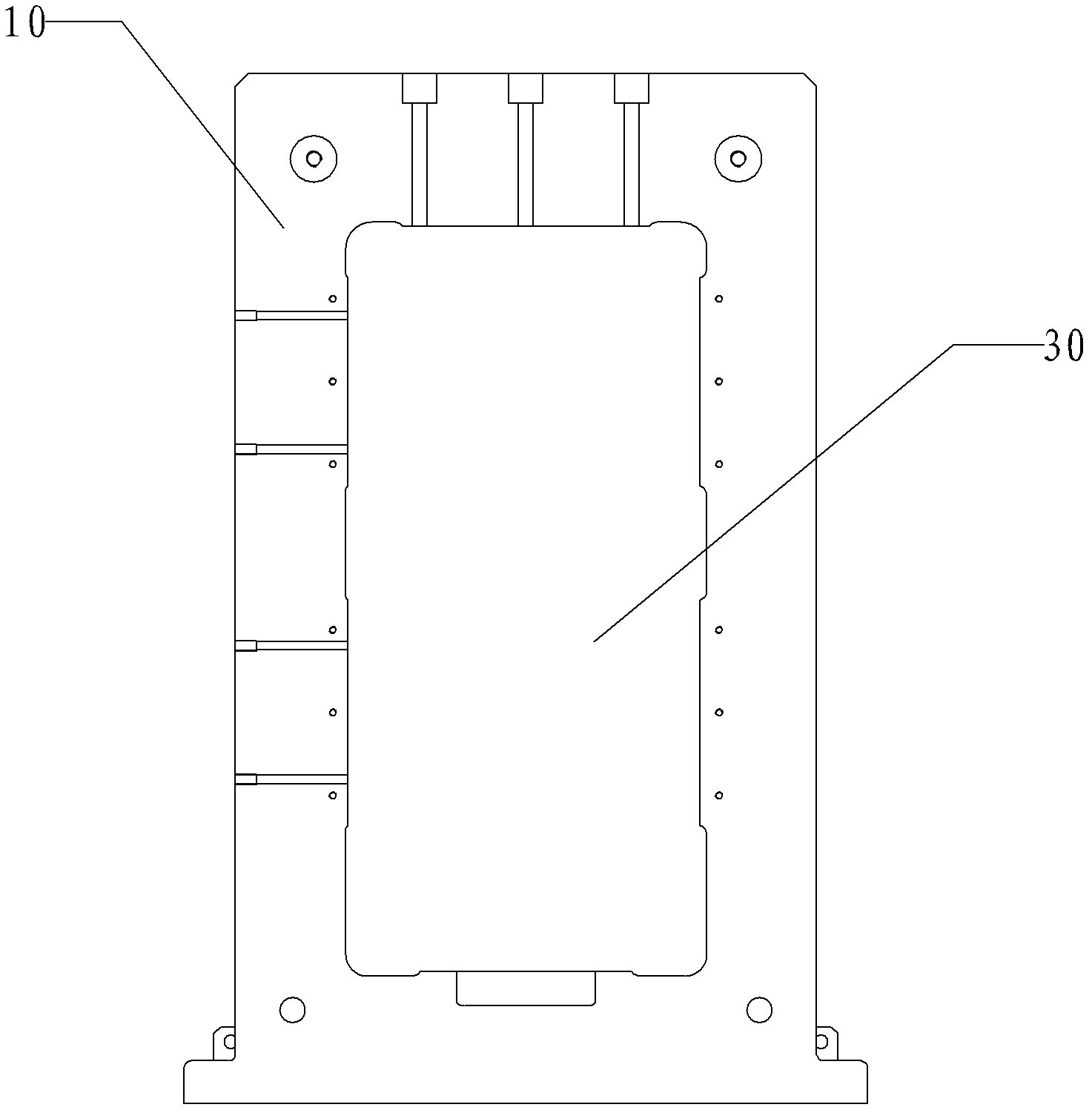

[0019] refer to Figure 1 to Figure 4 As shown, the frame of the battery pole piece rolling machine of the present invention includes a left frame 10 and a right frame 20, and the left frame 10 and the right frame 20 are respectively provided with bearing seats for placing roll ends. The carrying port 30, the shape of the carrying port 30 is a closed mouth shape, and also includes an upper connecting foot 40, an upper connecting piece 50, a lower connecting foot 60 and a lower connecting piece 70, the left frame 10 and the right frame 20 The upper ends of the upper ends protrude inward respectively to be provided with the upper connecting pins 40, the upper connecting pins 40 on the left frame 10 and the upper connecting pins 40 on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com