Production process and device of a fully enclosed hydraulic composite bimetallic steel pipe

A bimetallic steel pipe and hydraulic composite technology, which is applied in the field of hydraulic composite metal pipes, can solve problems such as bending of finished products, uneven deformation of steel pipes, blasting, etc., and achieve constant elastic deformation, ensure mechanical properties, and uniform elastic deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

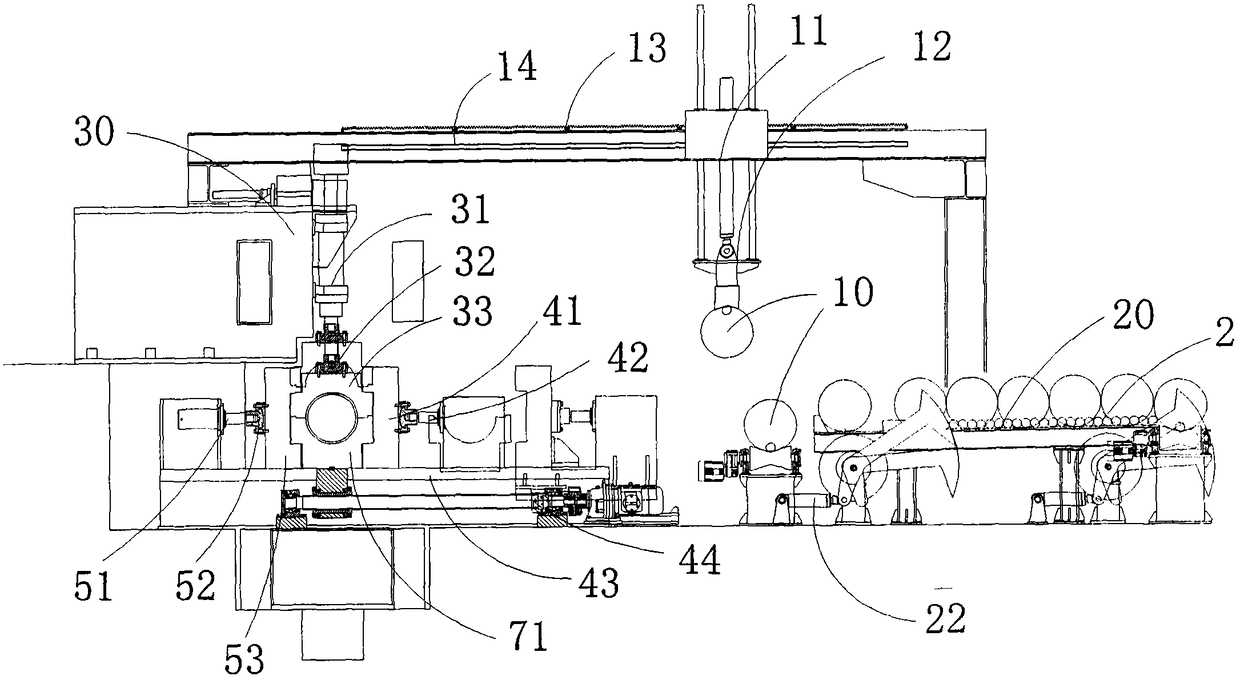

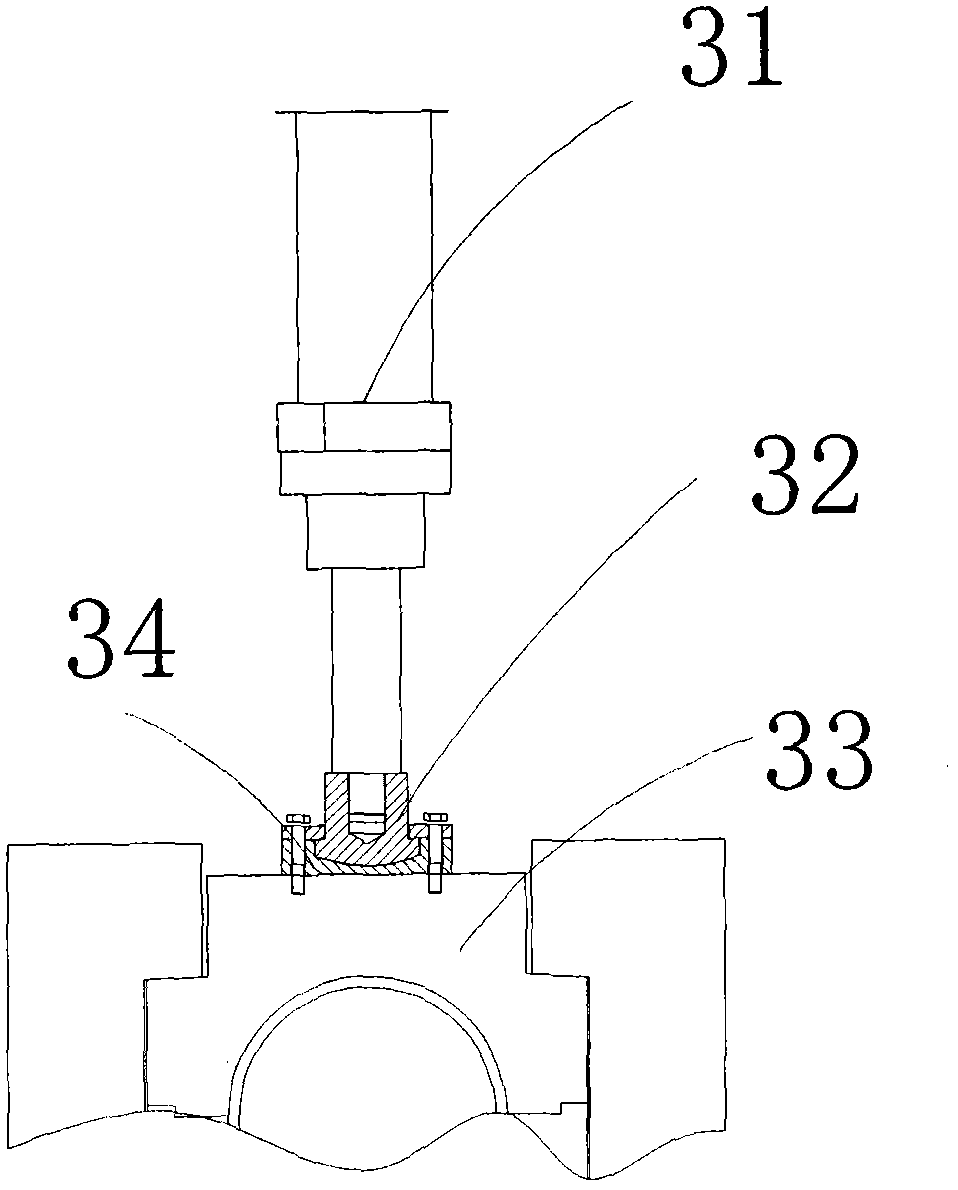

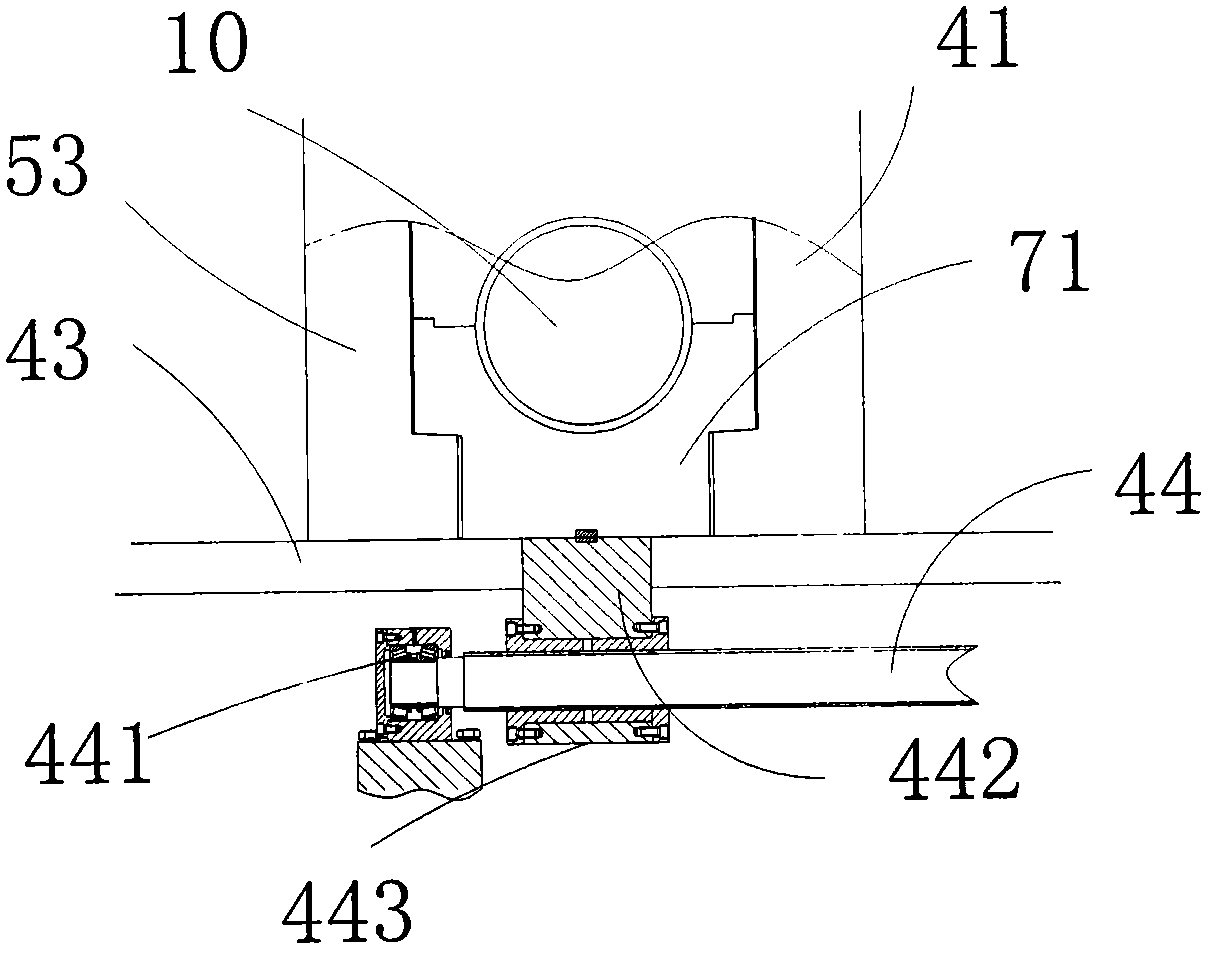

[0033] see Figure 1a As shown, it is a schematic cross-sectional structure diagram of the fully enclosed hydraulic composite bimetallic steel pipe production device of the present invention; the fully enclosed hydraulic composite bimetallic steel pipe production device of the present invention includes a material inlet and outlet unit 20, a lifting and hanging pipe unit 11, and an upper clamp device 30. Lower clamp device, left locking device, right locking device, left test head assembly, right test head assembly and supporting hydraulic system and electric control system; wherein, through the above-mentioned upper clamp device, lower clamp device, The left locking device and the right locking device hold the base pipe and control the elastic deformation of the base pipe so that the combined deformation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com