Slab width detection system and detection method

A technology of width detection and slab, which is applied in the direction of length measuring device, metal processing equipment, metal rolling, etc., can solve the problems of excessive width and dimension deviation of raw materials, a large amount of money for width measuring equipment, and defective finished strip steel, etc., to achieve Reduce scrap rate, avoid product width defects, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

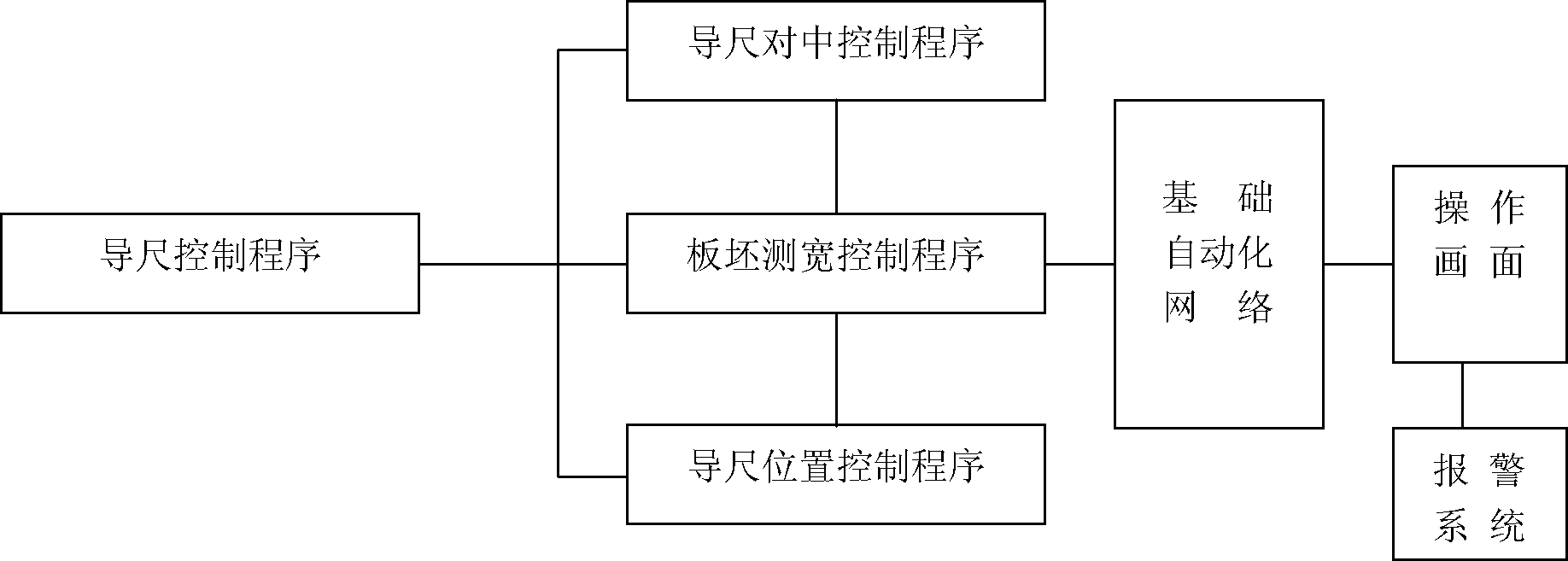

[0017] It can be seen from the attached drawings that the slab width detection system is mainly composed of guide ruler centering control program, guide ruler position control program, slab width measurement control program, basic automation network, operation screen and alarm system. In the present invention, a slab width measurement control program is added to the original control program of the guide ruler of the fixed-width press. The slab width measurement control program is also connected to the basic automation network, which communicates with the operation screen, and the operation screen is connected to the slab deviation alarm system, so as to quickly record, feedback, calculate and display the slab width deviation, and send out an alarm Alert slab width detection control system.

[0018] The slab width detection control process and concrete steps of the present invention are:

[0019] 1. Before the slab enters the fixed-width press, the entrance guide bar is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com