Industrial flexible object detection method based on machine vision

A technology of flexible objects and detection methods, applied in instruments, computer parts, image analysis, etc., can solve problems such as relative blanks, and achieve the effect of high real-time performance and low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

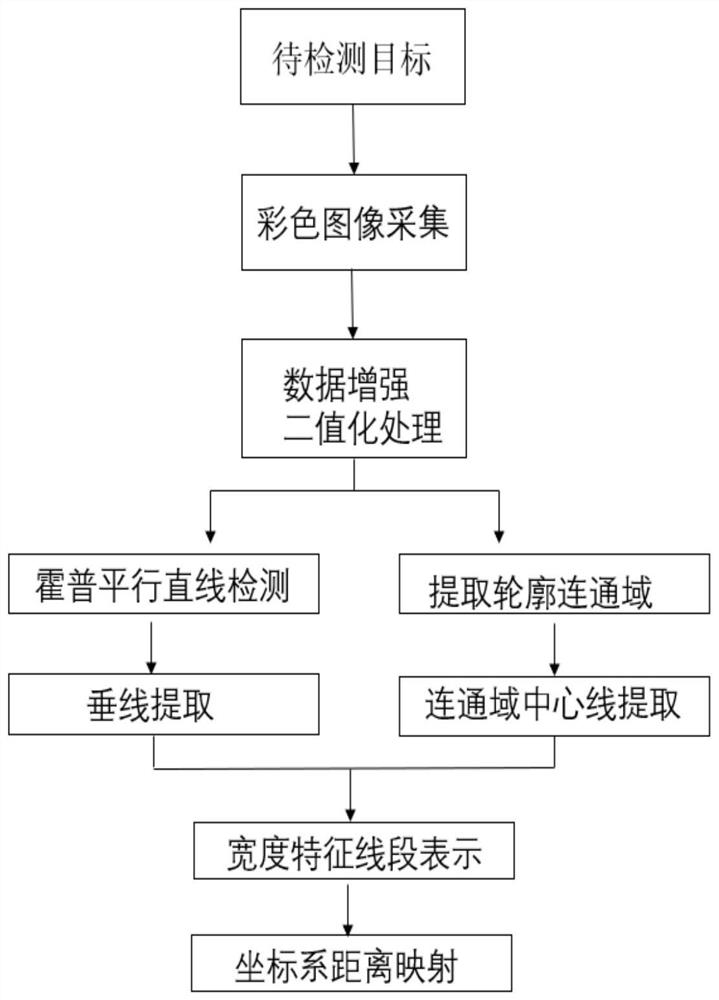

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The existing method for detecting industrial flexible targets is usually the projection method. This method is usually to select a product pattern with a regular appearance and contour produced by cutting on the assembly line and paste it on the sample holder, and use the magnifying glass scale method / digital The projector measures the target, selects the width measurement value of multiple positions for each target, and uses the average value of the width measurement of all sample product measurement points as the final width measurement value of the target. This method takes a long time and has low real-time performance. In addition, during the selection of the target product and the clamping process, the external force will have a seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com