Dual-elbow-rod punch

A technology of double toggle lever and punching machine, which is applied to punching machines, presses, manufacturing tools, etc., can solve the problems of reducing the service life of the slider and the slider guide seat, the body of the punching machine is heavy, and the mass distribution is unbalanced, etc. Achieve the effect of improving dynamic performance, small energy loss and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

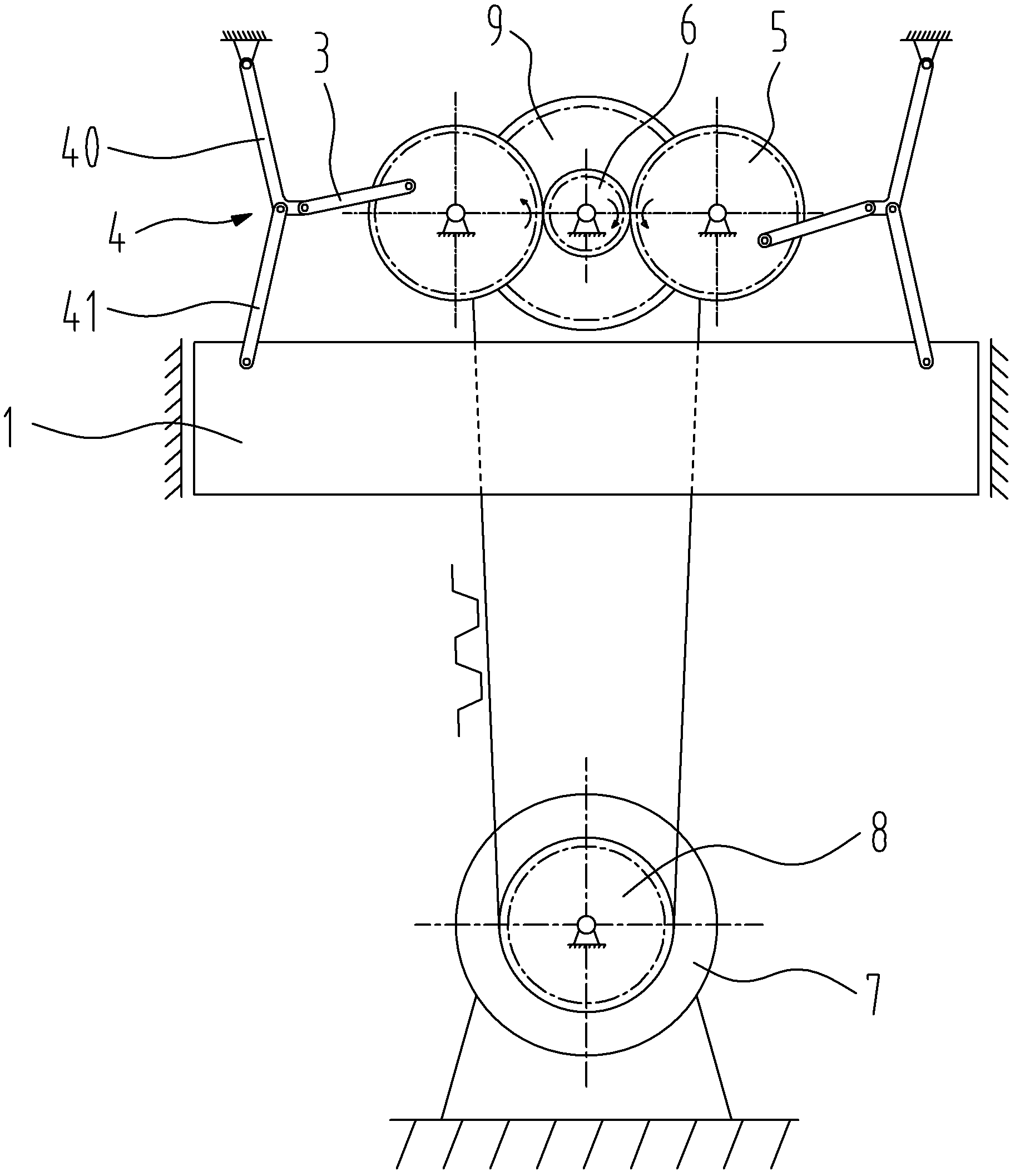

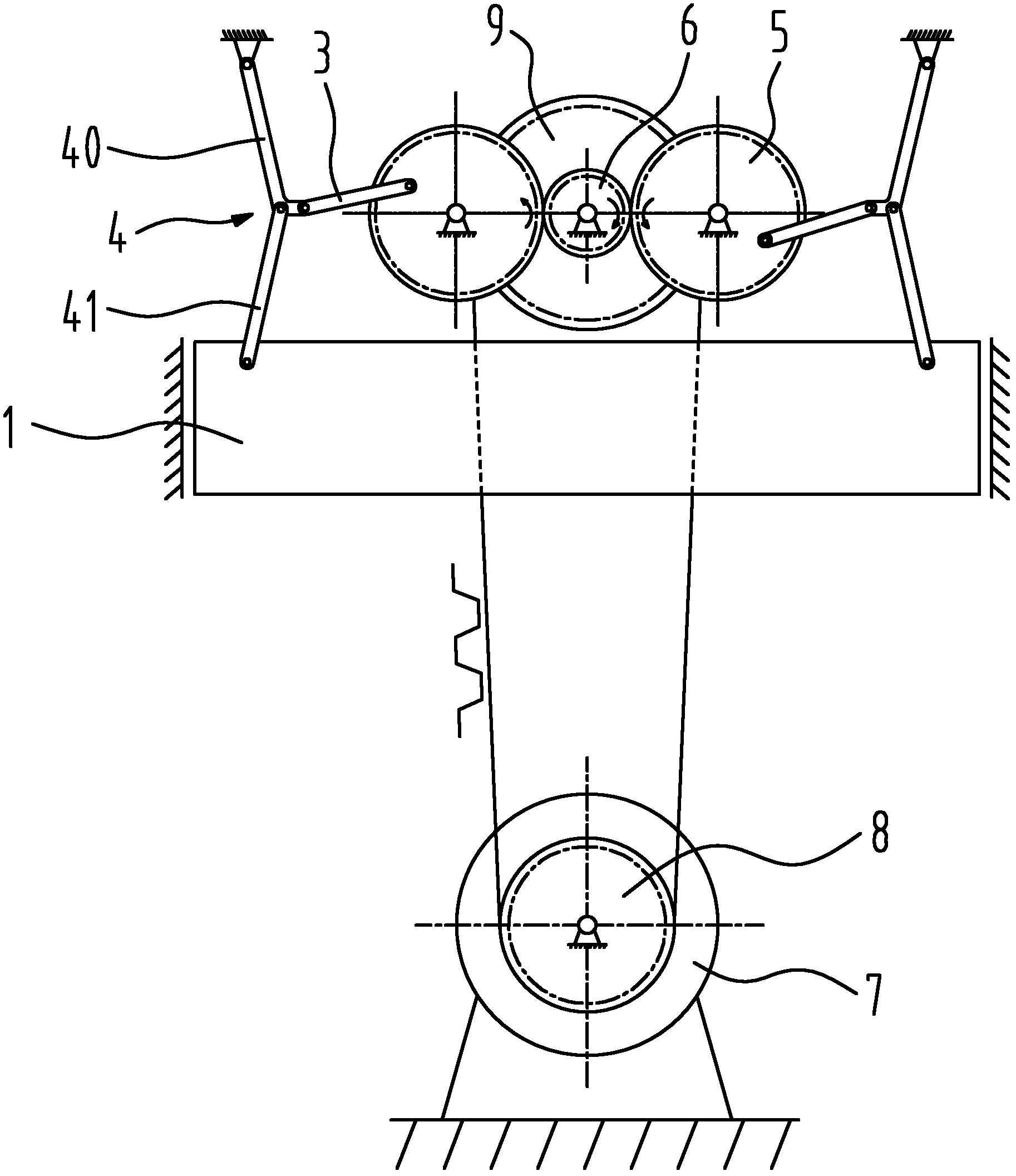

[0026] Embodiment one: see figure 1 As shown, a double toggle punch is provided with a punch 1, including a driving gear 6 and two driving mechanisms, and the driving mechanism is composed of a driven gear 5, a connecting rod 3 and a bilateral toggle mechanism 4. The bilateral toggle mechanism 4 is hinged by an upper toggle 40 and a lower toggle 41, one end of the connecting rod 3 is eccentrically hinged on the driven gear 5, and the other end is hinged with the upper toggle 40 of the bilateral toggle mechanism; The upper end of the upper toggle 40 is hinged on the punch body, and the lower end of the lower toggle 41 is hinged on the punch 1 .

[0027] The two driven gears 5 are symmetrically meshed on both sides of the driving gear 6 , and the hinge points between the connecting rod 3 and the driven gear 5 in the two driving mechanisms are symmetrical about the rotation center of the driving gear 6 .

[0028] Described double toggle type press also includes the motor 7 that ...

Embodiment 2

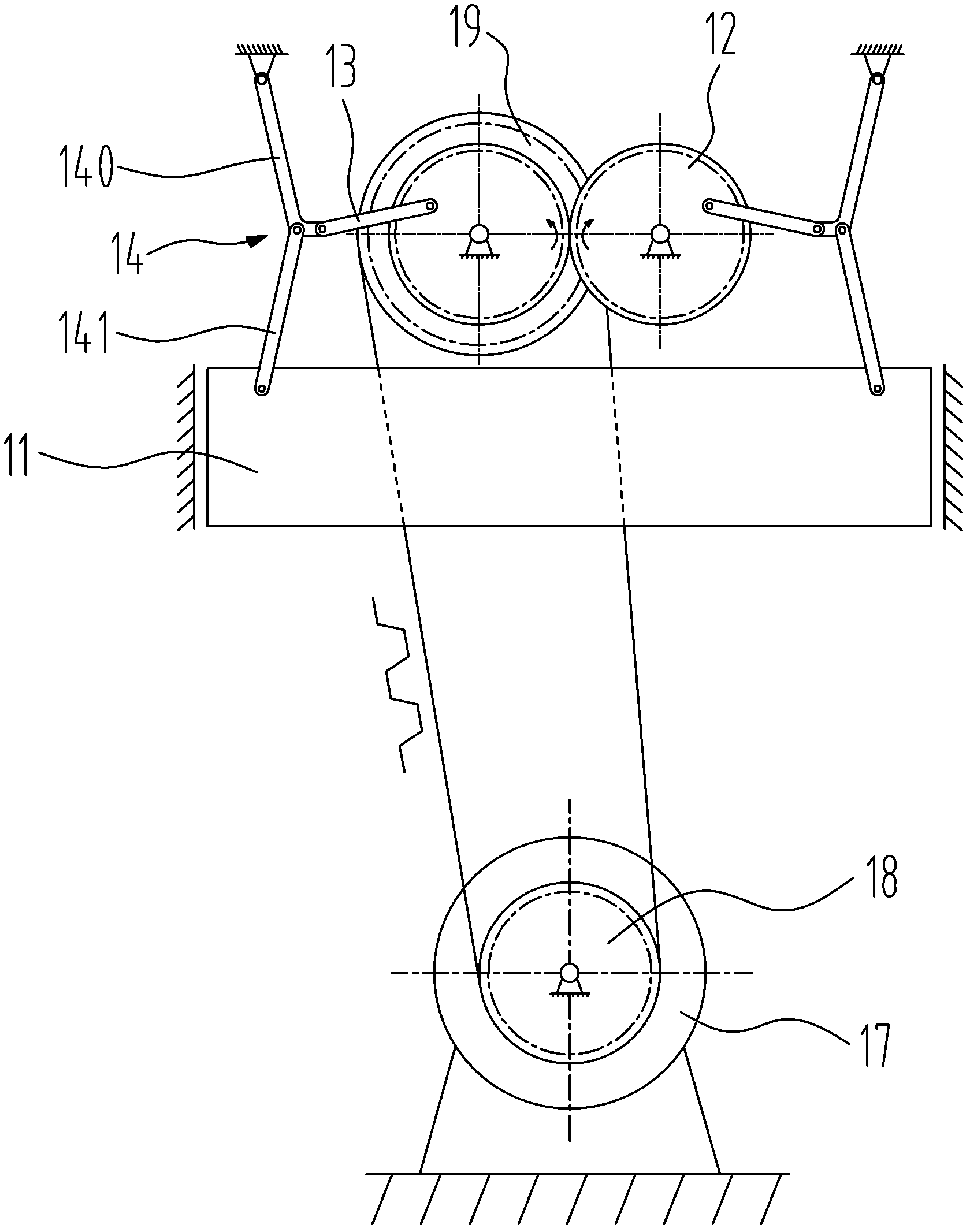

[0032]Embodiment 2: A kind of double-knuckle-type punch press, on which a punch is provided, including two identical transmission mechanisms symmetrically arranged in the horizontal direction, the transmission mechanism is composed of gears, connecting rods and bilateral toggle mechanisms, and the bilateral The toggle mechanism is hinged by an upper toggle 140 and a lower toggle 141, one end of the connecting rod 13 is eccentrically hinged on the gear 12, and the other end is hinged with the upper toggle 140 of the bilateral toggle mechanism; the upper toggle The upper end of 140 is hinged on the punch body, and the lower end of the lower toggle 141 is hinged on the punch.

[0033] Described double toggle type punch press also comprises the motor 17 that is located at double toggle type punch below, is fixed on the driving pulley 18 on the motor shaft, belt and driven pulley 19, and described driven pulley 19 and wherein A gear 12 is coaxially fixed, and the axes of the two ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com