Method for stamping precisely porous bottom plate for sealing

A technology for stamping and sealing, applied in the field of stamping, which can solve the problem that the surface roughness and the position and size of the holes do not meet the design requirements, the quality of the bottom plate cannot meet the design requirements, the dimensional accuracy of the extrusion ribs of the bottom plate is difficult to meet the requirements of the design drawings, and the equipment and operations occupied Problems such as too many personnel, to achieve the effect of ensuring position accuracy and surface roughness requirements, good quality consistency, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

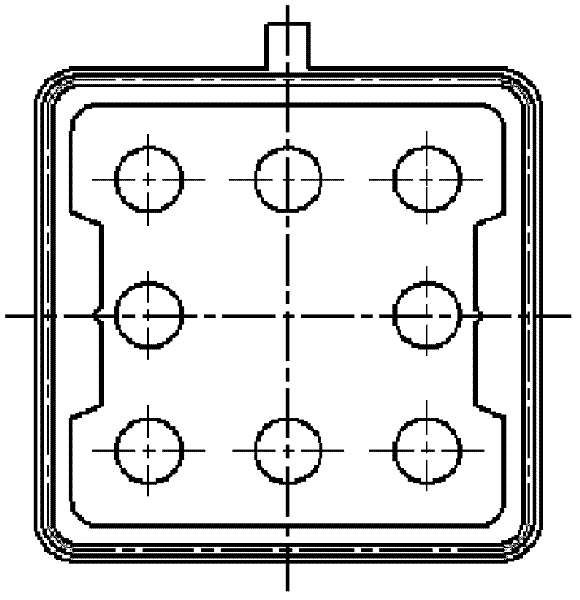

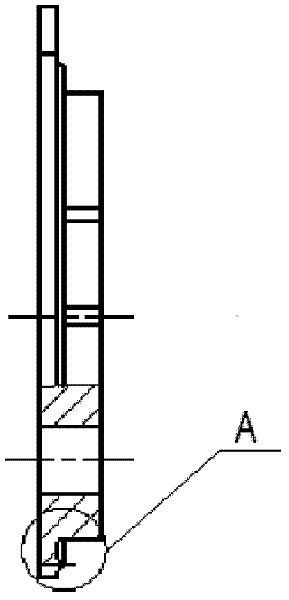

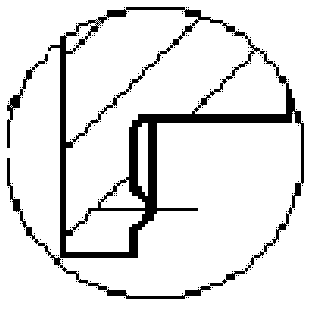

[0025] Example 1. Such as Figure 1-Figure 11 As shown, the precision porous base plate for sealing is composed of 8 holes, bosses and ribs. The stamping method of the base plate is: the strip material is fed into the mold according to the step distance through the automatic feeder, and the press (punch) Next, complete the following steps: step 1 punching, step 2 guiding, step 3 guiding, step 4 punching waste, step 5 empty step, step 6 empty step, step 7 punching waste, step 8 Step empty step, step 9 punching pre-hole, step 10 punching pre-hole, step 11 empty step, step 12 extrusion platform, step 13 empty step, step 14 extrusion rib, step 15 empty step, step 16 Step empty step, step 17 fine punching, step 18 empty step, step 19 blanking, while blanking step 19, steps 1 to 18 are also carried out simultaneously, so that the press (punch) moves At one time, the stamping and forming of a bottom plate can be completed. Steps 1 to 19 are carried out simultaneously in one pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com