Method for turning and milling to realize typical characteristics of aircraft landing gear

A technology of aircraft landing gear and processing method, which is applied in the fields of processing technology and mechanical processing technology to achieve the effects of avoiding tool marks, improving processing efficiency and improving clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] See Figure 11 , a typical characteristic turning and milling processing method of an aircraft landing gear of the present invention, the specific steps of the method are as follows:

[0055] 1. Orthogonal turning and milling roughing.

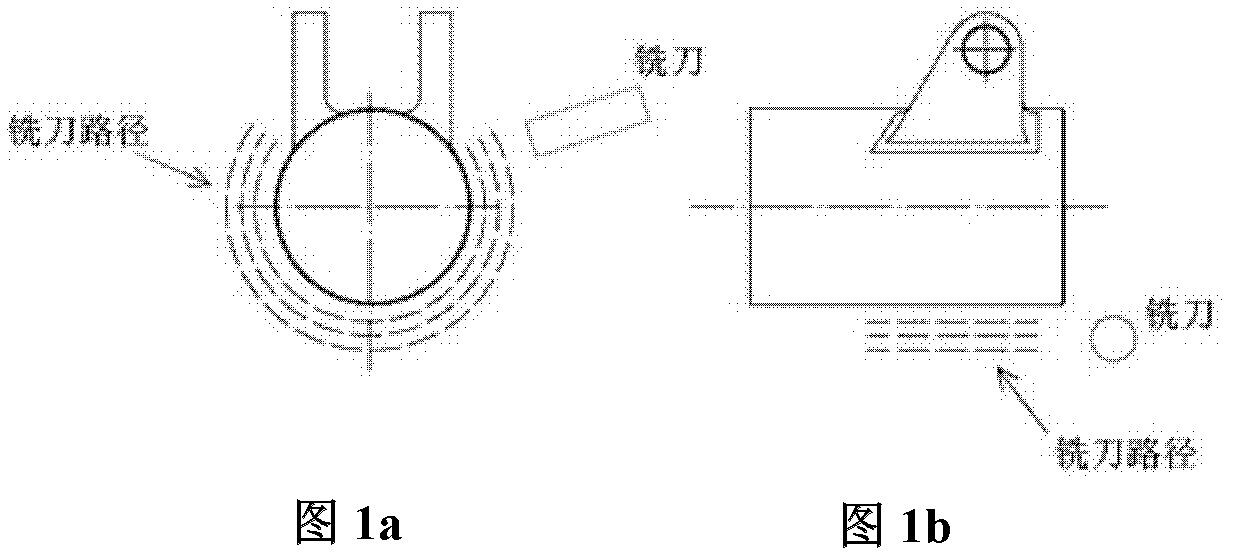

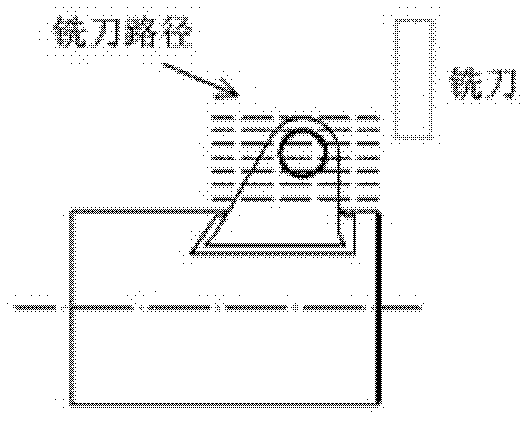

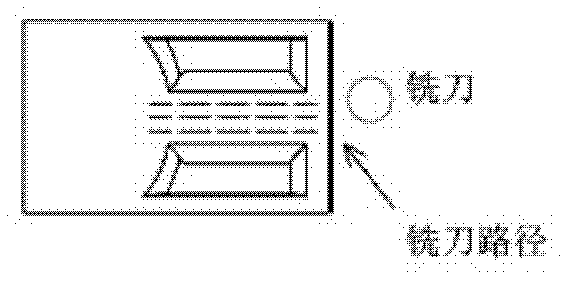

[0056] Prepare the blank, put it on the machine tool and clamp it for positioning. Orthogonal turning and milling of the landing gear lugs to remove most of the margin, such as Figure 1a , Figure 1b . The selected tool is a flat-bottomed fillet milling cutter, the tool diameter is recommended to be 20%-40% of the workpiece diameter, the Y-axis eccentricity is set to 50%-70% of the milling cutter diameter, and the processing method is forward and reverse milling, X, Y, Z, C four-axis linkage processing, the finishing allowance is about 0.2mm.

[0057]Due to the particularity of the clamping of the turn-milling machine tool, the rigidity of the tooling is generally poor. Therefore, the depth of cut should not be too large during pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com